- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- composites

Results for

Composites - Import export

ISOVOLTA AG

Austria

Bare, uncovered Laminates based on commercial style glass fabrics

Request for a quote

ISOVOLTA AG

Austria

As 1B Laminate but with white Tedlar on one of the two sides

Request for a quote

ISOVOLTA AG

Austria

High performance laminate based on a matrix of modified phenol pressed in multilayers with fibre glass, for use in aircraft interiors, meets FST requirements in accordance with FAR 25.853 and FAR 25.855

Request for a quote

ISOVOLTA AG

Austria

Prepreg with a modified phenolic resin system specially developed for processing in presses (crushed core) where short processing cycles can only be achieved through higher cure temperatures with lay-ups and de-moulding in presses that are still hot (hot in / hot out).

Request for a quote

DEMIR SAFETY

Turkey

-Composite Toecap -Double density PU outsole, PU midsole -Breathable, suede leather air file textile -Abrasion resistant breathable sweat absorbent textile.

Request for a quote

DEMIR SAFETY

Turkey

-Composite Toecap -Double density PU outsole, PU midsole -Breathable, water resistant, printed screw leather -Abrasion resistant breathable sweat absorbent textile

Request for a quote

DEMIR SAFETY

Turkey

-Composite Toecap -Double density PU outsole, PU midsole -Breathable, water resistant crazy leather -Abrasion resistant, air permable high quality airfile textile.

Request for a quote

DEMIR SAFETY

Turkey

-Composite Toecap -Double density PU outsole, PU midsole -Breathable suede leather, air file textile -Abrasion resistant, air permable high quality airfile textile.

Request for a quote

KOLAS ALUMINYUM A.S.

Turkey

Composite sheets are strong and can be preferred in larger openings compared to other building materials. According to the different designs of modern architecture, they can be applied as desired. Aluminum composite panel facades are one of the first choices of customers who want to have a different design especially for aesthetic concerns. If you need such a system, you can contact us without any hesitation.

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

PU composites are mainly found in the production of moulded parts resistant to bending. The skilful combination of materials puts the topic of lightweight construction into the spotlight (honeycomb technology applications). Sophisticated surface designs are supported by corresponding PU / UP resin systems. Thanks to the reduced component weight, moulded part applications are used in the automotive sector – and, with corresponding flame protection formulations, also in rail vehicle construction. Typical properties Moulded part density of 450–1100 kg/m³ Fibre proportion from 30 % Available foaming agents: usually water Reinforcing materials Glass fibre rovings Glass fibre mats and non-crimp glass fibre fabrics Carbon fibres Natural fibres (hemp, sisal, coconut etc.) Special formulations and versions Honeycomb materials for sandwich structure components Paper honeycombs Waterproof paper honeycombs (patent-pending process) Plastic honeycombs Aluminium honeycombs Systems with a large processing window Use of polyols based on renewable resources Self-parting with simultaneous good lamination properties Flame protection formulations Automotive: FMVSS 302 Rail vehicle construction: DIN 5510 (S4, SR2, ST2) Aircraft construction: FAR 25853, ABD 0031 Construction industry: DIN 4102 B2

Request for a quote

UMIT ALUMINIUM

Turkey

* For standard 4mm thick Alfabond composite panel: * Sheet Alloy - Condition : EN AW-3105 / H46 * Aluminium Sheet Thickness : Üst Levha / Top Sheet: 0,30mm (±0,02mm) * Bottom Sheet: 0,30mm (±0,02mm) * Composite Panel Total Thickness : 4mm (±0,2mm) * Filling : Yangın Tepki Sınıfına Göre Değişken - Kalınlık: 3,4mm * Depending On The Flammability Class - Thickness: 3,4mm * Top Sheet Coating : Kynar 500 Bazlı HDP Boya (20+5 mikron) * Kynar 500 Based HDP Paint (20+5 micron) * Bottom Sheet : Polyester Based Protective Paint

Request for a quote

BAUENZ TECHNOLOGY LTD

United Kingdom

Today, on the market of innovative building materials, composite mesh is the best solution! Composite mesh is a glass fiber thread bonded with epoxy resin. Replaces a metal mesh. Does not magnetize, does not conduct electricity. Not a "bridge of cold". Composite fiberglass mesh is elastic. It is produced by us on the most modern high-tech equipment in two convenient formats - cards or rolls.

Request for a quote

BIOPOWDER.COM (SCHILLING LTD.)

Malta

Fine micronized powder/granules as a bio-filler material for the following applications: 1. Cosmetics: cosmetic filler and abrasive - microbead replacement 2. Polymer Applications (thermoplasts, duroplasts, resins) 3. Paints, Adhesives, Resins: reactive filler Our product can be supplied in a variety of micron size ranges - from fine powders in the nano and micrometer range up to coarse granules of several millimeters. Product variants are: 1. Natural grade: untreated, consisting of 100% olive stones in food quality 2. Irradiated grade: sterilized grade 3. Silane-treated grade: hydrophobic variant 4. Colored grade: permanently colored bio-flakes We ship small and large volumes worldwide.

Request for a quote

IMICRYL DENTAL PRODUCTS

Turkey

Universal Composite, nano-hybrid, light curing

Request for a quote

TFP TECHNOLOGY GMBH

Germany

With our CNC-wire-laying technology is it very easy to integrate functions like heaters for Anti-Icing/De-Icing or surface sensors for detections of structural problems in carbon or glass fiber parts. We can manufacture dimensions up to 2500x8000mm.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Ceramic Composites Elevate your applications with our PEEK ceramic composite. This advanced material combines the exceptional properties of PEEK with the added strength and durability of ceramic. Experience enhanced mechanical performance and wear resistance, making it the perfect choice for demanding industrial solutions. Choose PEEK filled with ceramic for precision and resilience in extreme conditions.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALUXFOIL - BAZIS GMBH

Hungary

18my aluminium / glass fibre fabric / PE composite foilThe polyethylene coating allows welding to the insulating material. For laminating on hard foam (PUR and PS) or on glass and rock wool, e.g. felt plates, pipe shells. steam-tight Sd-value > 1500 m heat-reflecting

Request for a quote

LISINE EPSTEIN COSMETICS BV

Belgium

A composition with fresh and oriental notes, combining the powerful energy of lemon with the warm oriental accords of sandalwood, vetiver and vanilla. Top notes are Lemon and Bergamot Middle notes are Sandalwood and Woody Nuts Base notes are Vanilla and Vetiver. Parfen N° 686 is a new dimension of style, a perfect balance between formal elegance and confident uniqueness. An explosive alchemy of hot and cold. Exudes a masculine allure with a unique charm. A truly creative statement. This lemon accord gives the perfume energy that continues into the heart where sandalwood and tonka await you. The sweetness of both ingredients covers the lemon. It adds more depth without completely overpowering the citrus. The base uses vetiver and vanilla to give the final finishing touch. Vetiver takes the sandalwood in a more traditional woody direction. The vanilla harmonizes with the tonka for a comforting accord. All this while the lemon pulses in the middle of it all.

Request for a quote

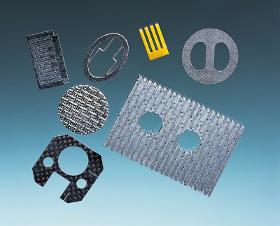

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in assemble flashlight accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are made by aluminium, used for the mechanical support and connection, after process then doing sandblasting + natural oxidation.

Request for a quote

ID GROUP

France

2 in 1: antifatigue and antistatic function quick and efficient dissipation of static electricity thanks to the upper surface which is connected with a ground cord exceptional comfort thanks to high quality nitrile foam improves employee productivity bevelled edges to avoid the risk of falling Resistivity from 106 to 109 Ohms conforms to standards EN 1000151, IEC 6134052 and EN 1815

Request for a quoteResults for

Composites - Import exportNumber of results

367 ProductsCountries

Company type

Category

- Aluminium alloys (63)

- Woodworking - machinery and equipment (22)

- Frameworks, concrete (13)

- Bearings - ball, needle and roller (11)

- Coatings, insulating (10)

- Knives, industrial (10)

- Façade work contractors (9)

- Flame retardant construction materials (9)

- Woollen fabrics (9)

- Footwear, safety (5)

- Acoustic panels (5)

- Cables & Networks (5)

- Couplings, mechanical (5)

- Cosmetics (4)

- Façade bricks (4)

- Shearing - steels and metals (4)

- Steel (4)

- Windows, aluminium (4)

- Aluminium coatings (3)

- Bronze (3)