- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine vision system

Results for

Machine vision system - Import export

QUELLTECH GMBH

Germany

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

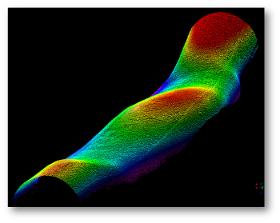

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

PLANISTAR LICHTTECHNIK GMBH

Germany

Flat led backlight system with border illumination for transmitted light- and contour applications for machine vision systems. At nearly all of our back lightings we are working with border illumination. The LEDs are not situated in the lighting area itwelf but below the unlighted edge. The light of the LEDs will be injected into the border of a flat light conductor and uncoupled equally via a calculated dot matrix system. This technique comes originally from the premises of planistar. The dot matric course are sitll being calculated from us an manufactured ba very precise UV print machines. So the square light has an very diffus and even light on the measuring surface. We can produce from very small led lights to very big monster lights every size you need for your vision light system. The high-power led backlights are with switch input for steady or flashing. The controller for the current are always inside.

Request for a quote

PLANISTAR LICHTTECHNIK GMBH

Germany

workplace light with a special reflector technology: Highly effective task luminaire light with a very uniform illumination of the workplace. The high quality light for working places and inspection tables with a very efficient reflector system makes an very homogen light on the table. You will have an very good color spectrum >RA85 and an light color of 5000K. robust machine light: machine light and general light with high light output. Using for machine lighting and industrial vision systems. The have no IR and UV spectrum. signal lights according to customer specification: edge light systems and border illumination: lightpanels for border illuminations. The LEDs are not situated in the lighting area itwelf but below the unlighted edge. The light of the LEDs will be injected into the border of a flat light conductor and uncoupled equally via a calculated dot matrix system. This technique comes originally from the premises of planistar. The dot matric course are sitll being calculated from us an manufactured ba very precise UV print machines. The main advantage of this system ist the hight constancy o fhte illumination area also for a long period of time. An unequal aging or unequel brigntness's of the particular LED ships will be distributed through the light conductor in the shortest distance.

Request for a quoteResults for

Machine vision system - Import exportNumber of results

9 ProductsCountries

Company type