- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine vision system

Results for

Machine vision system - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories use for mechanical housing.

Request for a quote

QUELLTECH GMBH

Germany

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

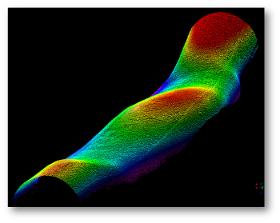

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

SAMSYS GMBH

Germany

With the robot camera Eyes from OnRobot, the provision of image processing for almost all collaborative applications becomes easy and cost-effective. Eyes is suitable for the sorting of a large number of objects. For example for CNC machines with metal parts defined by their outer shape and many other pick-and-place applications where alignment is important. Calibration and part recognition with only one single shot takes only a few minutes. Programming is intuitive and fast. And with Eyes’ advanced, affordable 2.5D vision, you benefit from depth perception and the ability to stack parts without adding complexity. The simple one-system setup for all leading robot manufacturers comes with software that is easy to install and program. Even employees without a technical background can perform the setup. Calibration and part recognition with a single shot. Simply take an image of the work surface to calibrate the camera view. One image for each part you want the system to detect.

Request for a quote

LEICA MICROSYSTEMS

Germany

Streaming directly and live HD-images from the microscope to the student’s mobile end devices:These 5-megapixel cameras make it possible! With the ICC50 W and its integrated Wi-Fi-signal several tablets and smartphones can be connected with the microscope camera. This way, images send per live stream can be captured with the own output device immediately. The ICC50 E uses the Ehternet, to connect the student’s output devices with the camera. With the specially developed Leica AirLab App images easily can be captured, measured, archived and shared via social networks by Students. The app is available for iOS and Android, free of charge, in iTunes or Google Play.

Request for a quote

LEICA MICROSYSTEMS

Germany

Inspection and review system for the inspection of samples with a diameter of 12 inches/300mm. Integrated macro mode for four times the field of view of conventional scanning objectives. Top resolution from any angle with the Oblique UV mode (OUV), which combines oblique illumination with UV light. Optimized airflow in the cleanroom due to the integrated LED illumination. With only one touch of a button magnification, illumination and contrast methods can be changed.

Request for a quote

LEICA MICROSYSTEMS

Germany

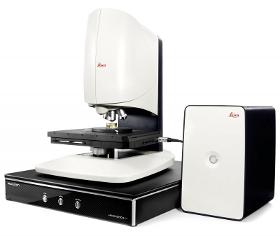

Optical profilometer for contactless 3D surface metrology. Combines confocal metrology in HD with interferometry to a versatile dual core system. High-performance software, simple module selection with one click and confocal scanning without movable parts help to make the analysis very efficient and fast. HD confocal measurement with vertical resolution up to 2nm for surfaces with sloping areas and intricate structures. Interferometry with a resolution up to 0,1 mm for even surfaces with microstructures. Fast, reproducible data capture due to innovative HD microdisplay scanning technology without any movable parts in the sensor head. The integrated HD CCD-Camera has an extra-large field of view, for the analysis of bigger areas. Realistic color imaging due to four varicolored LEDs in the sensor head.

Request for a quote

LEICA MICROSYSTEMS

Germany

Reliable and easy to handle inspection microscope for routine tasks in metallography, earth science, forensic investigation, materials quality control and research. Constant color temperature for all contrasting methods thanks to the universal LED-illumination. Smallest surface structures and defects are visualized due to the integrated oblique illumination. The macro objective with a 0.7x magnification enables you to see 40mm of the sample at a glance. Three objective series for selection, objective magnifications from 0.7x up to 150x. Simple, fast and accurate adjustment of objective magnification, contrast and depth of field with the Color Coded Diaphragm Assistant.

Request for a quote

POLYPLAST MÜLLER GMBH

Germany

Because quality is the basis for your success, we offer you our knowhow and our production facilities for contract manufacturing Many wellknown manufacturers take advantage of this service and develop – jointly with Polyplast Müller – specific products that are exclusively manufactured. Every product is developed jointly with you in our wellequipped quality laboratories that greatly exceed industrial standards. Stateoftheart production processes such as Buss kneaders, twin screw extruders, as well as continuous and discontinuous mixers can be selected for the most varied applications. At the same time, the extensive quality assurance system ensures consistent product quality. The stricter the requirements, the more attractive will be the challenge for the Polyplast Müller engineers – because only when we can put our entire expertise to work will the product be optimal.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight D900 is a smart camera powered by In-Sight ViDi software designed specifically to run deep learning applications. This embedded solution helps factory automation customers easily solve challenging industrial OCR, assembly verification, and random defect detection applications anywhere on the line that have gone uninspected because they are often too difficult to program with traditional, rule-based machine vision tools. In-Sight ViDi applications are deployed on the In-Sight D900 smart camera without the need for a PC, making deep learning technology accessible to non-programmers. It uses the familiar and easy-to-use In-Sight spreadsheet platform which simplifies application development and factory integration.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. The In-Sight 5705C offers color image filtering in addition to grayscale filtering and allows you to train multiple color models using the color library to identify which color the target part is. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7900 series is a full-featured, high-resolution and flexible vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 2800 vision system combines deep learning technology with traditional rule-based vision tools to solve a wide range of applications. From simple presence/absence detection to advanced categorization and sorting tasks, In-Sight 2800 provides an easy to deploy solution for error-proofing. Designed for factory automation, In-Sight 2800 enables manufacturers of all size to: — Increase product quality – Catch small, subtle defects with optimized error detection. — Maximize operational efficiency – Leverage your existing workforce and keep your lines running with fast, intuitive job setup. — Streamline integration – Take the guesswork out of image optimization and identify the correct combination of accessories in a few button clicks. Automate error detection in minutes – no experience required

Request for a quote

COGNEX CORPORATION

Germany

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers: — High scan rates (up to 18 kHz) at full measurement range — Maximum resolution images (2,000 profile points) — Fast high dynamic range (HDR) image These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

Request for a quote

COGNEX CORPORATION

Germany

Machine vision tools and barcode reading systems produce a lot of insight-rich data across manufacturing and logistics facilities. The expansion of Industry 4.0 through the Industrial Internet of Things (IIoT) focuses on improving operations by collecting and analyzing data in an efficient way like at “the edge” of the production line as opposed to sending data to the cloud and back. The Cognex Edge Intelligence (EI) platform transforms big data into smart data and provides real-time system performance monitoring and device management to improve overall equipment effectiveness (OEE) and throughput. EI device setup is fast and simple for both new and existing automation lines, preventing downtime and boosting productivity for your operation. Easily connect to the EI platform through any web browser to start collecting data right away. Additionally, users can configure and manage several devices at once.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 3D-L4000 is a breakthrough in three-dimensional (3D) vision technology. This unique vision system combines 3D laser displacement technology with a smart camera allowing factory engineers to quickly, accurately, and cost effectively solve a wide variety of inspections. The patented speckle-free blue laser optics, an industry first, acquires high quality 3D images and on-board high-performance processing powers a comprehensive set of true 3D vision tools, without the need for external processing. 3D vision tools are set up as easily as 2D vision tools thanks to the familiar and robust In-Sight spreadsheet environment. The intuitive In-Sight spreadsheet interface quickly and easily sets up and runs 3D applications without the need for programming. The In-Sight 3D-L4000 provides the capability to combine 2D and 3D vision tools in a single job to solve a wider variety of applications.

Request for a quote

EDMUND OPTICS GMBH

Germany

Edmund Optics® offers a wide range of Imaging Lenses suited for many imaging needs. Several TECHSPEC® Imaging Lenses are available that offer unique imaging capabilities that are not capable with standard lenses, such as TECHSPEC® Telecentric Lenses for edge contrast imaging or TECHSPEC® SWIR Imaging Lenses, which have been optimized for use with shortwave infrared wavelengths. A large selection of Imaging Lens accessories is also available including mounts or adapters for additional functionality.

Request for a quote

COGNEX CORPORATION

Germany

The 3D-A5000 offers a variety of fields of view and measurement ranges to accommodate applications in the automotive, consumer goods, and logistics industries. Other features and benefits include: — Patent-pending 3D LightBurst technology enables rapid image acquisition — More than 1.5 million 3D data points detect fine features on parts — High Dynamic Range (HDR) mode captures scenes with high contrast — Powerful 3D tools in VisionPro solve challenging 3D applications — Factory-calibration delivers results in real-world units — Rugged IP65-rated housing provides protection in harsh factory environments

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 2000 series vision sensors combine the power of an In-Sight vision system with the simplicity and affordability of a vision sensor. Ideal for solving error-proofing applications, these vision sensors set new standards for value, ease of use and flexibility thanks to a powerful combination of proven In-Sight vision tools, a simple setup, and a modular design featuring field-changeable lighting and optics. Together with the In-Sight Explorer EasyBuilder interface, which provides a fast, step-by-step application setup, these vision sensors allow even novice users to achieve extremely reliable inspection performance in nearly any production environment. In-Sight 2000 series vision sensors can also be configured for in-line and right-angle mounting installation. This modular body design provides maximum flexibility to mount in tight spaces, allows for customized wiring and optical paths, and minimizes the need to design new mechanical fixtures.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 2000C series vision sensors combine the power of an In-Sight vision system with the simplicity and affordability of a vision sensor. Ideal for solving error-proofing applications (monochrome or color), these vision sensors set new standards for value, ease of use and flexibility thanks to a powerful combination of proven In-Sight vision tools, a simple setup, and a modular design featuring field-changeable lighting and optics. Together with the In-Sight Explorer EasyBuilder interface, which provides a fast, step-by-step application setup, these vision sensors allow even novice users to achieve extremely reliable inspection performance in nearly any production environment. In-Sight 2000 series vision sensors can also be configured for in-line and right-angle mounting installation. This modular body design provides maximum flexibility to mount in tight spaces, allows for customized wiring and optical paths, and minimizes the need to design new mechanical fixtures.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7800 series is a full-featured, powerful vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quoteResults for

Machine vision system - Import exportNumber of results

40 ProductsCountries

Company type