- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- generating sets

Results for

Generating sets - Import export

NORIS GROUP GMBH

Germany

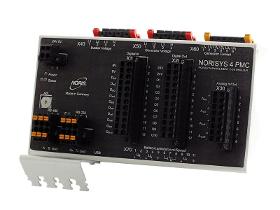

NORISYNC 4 is our new power management system (PMS) and optimises the generation and use of electricity. Core of the system is the new power management controller NORISYS 4 PMC. It is based on our open automation platform NORISYS 4 that was especially developed to automate marine applications. As a customised solution, NORISYNC 4 efficiently manage the power distribution, load depending start and stops of diesel generators, the load sharing, synchronising the generator set power and also the use of the energy storage system (ESS) of hybrid and fully electric propulsion systems. CPU based multi-master system for flexible system scalability Safety through redundant communication Different operation modes Easy system configuration Intelligent control of energy storage systems Standardised interfaces to higher level systems Remote access for maintenance and service Approvals in preparation: BV, DNV-GL, LR

Request for a quote

NORIS GROUP GMBH

Germany

Power Management Controller for power supply and system protection Can be used as an independent system or as an extension to a NORISYS 4 automation platform Option for connecting a colour touch panel as HMI and visualisation USB port for configuration and service RS-485 for NORISYS 4 ExtBus communication Generator set control with automatic start/stop function Parallel and isolated operation Automatic synchronisation Generator protection functions, 3-phase Power supply protection function, 3-phase Approvals pending: BV, DNV, GL, LR

Request for a quote

HEXPOL TPE GMBH

Germany

In the injection moulding process TPE pellets are fed into the machine through a hopper and then into a heated barrel. The heat from the barrel turns the material into a liquid resin which is then injected into a closed mould under high pressure. After allowing the molten polymer to cool, the finished part can be removed from the mould. Injection moulding is a high-volume, high tooling cost process, the advanced properties of our TPE compounds deliver short cycle times allowing parts to be produced at a rapid rate. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information Settings Equipment Conventional injection moulding machine Compression set At least 2:1. Special screws with short sections and higher compression ratios (3:1 to 4:1) may be good at low screw speeds Shrinkage Between 1.0% and 2.5% depending on the grade, type of application and location of the gate. Moul

Request for a quote

HEXPOL TPE GMBH

Germany

In the extrusion process the TPE pellets are poured into a hopper are heated in the barrel and turned into a melt by this heat and shear. A screw carries the melted plastic through a shaped die to produce continuous lengths of shapes with the same profile, which are then cooled by air or water. Our TPE compounds are easily extruded into single and complex profiles. They can also be co-extruded with other materials to yield a part with both rigid and soft components. They exhibit improved profile flexibility. The SEBS compounds, with their saturated intermediate blocks, are very stable against thermal degradation. On the other hand, the SBS compounds degrade if overheated or if a screw with excessively high compression ratio is used. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information SEBS based materials Equipment Extruders used for polyolefines are best for TPE comp

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Generating sets - Import exportNumber of results

4 ProductsCountries

Company type