- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- generating sets

Results for

Generating sets - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

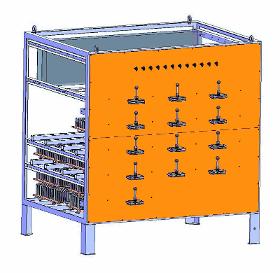

CSN® Load, Testing and Special Resistors are used to test generators and emergency generating sets to test battery capacity as dummy load when testing circuit breakers to discharge capacitors for starting, controlling and breaking of electric drives CSN® Load, Testing and Special Resistors are characterized by technically mature and proven design for operations both indoors and outdoors optimal design to suit all current values and load cycles reliable control of all operating voltages even in most adverse service environments longterm stability highly reliable technology CSN® Load, Testing and Special Resistors are designed and manufactured individually to customer requirements and specific application.

Request for a quote

LOSBERGER GMBH

Germany

The AMD Ultra-Fast Deployable Shelters provide an all-in-one shelter solution, where all equipment (air-conditioning, heating, groundsheet, sunscreen accessories, tools, lighting, generator set) is fitted on a single all-terrain trailer. This makes these shelters ideal for field maintenance operations in remote and hard to access areas. Thanks to their innovative hydraulic shaft system, AMD shelters are quick and easy to assemble with only two operators at ground level, and without the need for specific tools or engines. Their connectable groundsheet means the shelter is fully air- and watertight, while their integrated sunscreen helps limit air-conditioning power consumption.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Smart handling • The well-proven principle of operation of the GESIPA® hand riveting tool Flipper® spares up to 40% of the hand force for setting blind rivet nuts • A special lever design as well as the ratchet mechanism provide a reduction of hand force • Exchange of nosepiece and threaded mandrel • The total stroke is 9 millimeter long for setting of new generation multigrip blind rivet nuts like new the GESIPA® PolyGrip® blind rivet nuts • Tool-free setting of stroke and threaded mandrel lengths allows simple setting of blind rivets of different lengths Working range Blind rivet nuts from M3 up to M6 aluminium as well as from M3 up to M5 steel Technical data Total stroke: 9 mm Single action stroke: 1,8 mm Weight: 750 g

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Sentinel-ES™ Control Panel brings you the very best technology to monitor oxygen and dewpoint in situations where an in-situ probe is not practical. The combination of fast response times, low sensor replacement cost, no modifications necessary for your furnace or generator, and simple set-up and calibration make the Sentinel-ES™ an obvious choice for difficult applications.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers. Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORIS GROUP GMBH

Germany

NORISYNC 4 is our new power management system (PMS) and optimises the generation and use of electricity. Core of the system is the new power management controller NORISYS 4 PMC. It is based on our open automation platform NORISYS 4 that was especially developed to automate marine applications. As a customised solution, NORISYNC 4 efficiently manage the power distribution, load depending start and stops of diesel generators, the load sharing, synchronising the generator set power and also the use of the energy storage system (ESS) of hybrid and fully electric propulsion systems. CPU based multi-master system for flexible system scalability Safety through redundant communication Different operation modes Easy system configuration Intelligent control of energy storage systems Standardised interfaces to higher level systems Remote access for maintenance and service Approvals in preparation: BV, DNV-GL, LR

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN manufactures various cleaning machines acc. to ATEX (ATmosphère EXplosibles) for the use of combustible liquids. The cleaning machines can be used separately or in combination with other methods. The cleaning tanks must be operated at a well ventilated place. The combustible cleaning agent can be filled in directly into the tanks. The ultrasonic generators are set up separately. A safety thermostat (setting 15°C below the flash point) controls the adherence to a max. temperature and in case of excess temperature it switches the machine off. The cover included in the delivery avoids emissions from the tank during standstills. The machines can also be used in connection with aqueous cleaning methods. Options: • heating • extraction • cooling tube • ultrasonic frequencies 30 and/or 40 kHz • automation system • product carrier

Request for a quote

HEXPOL TPE GMBH

Germany

In the injection moulding process TPE pellets are fed into the machine through a hopper and then into a heated barrel. The heat from the barrel turns the material into a liquid resin which is then injected into a closed mould under high pressure. After allowing the molten polymer to cool, the finished part can be removed from the mould. Injection moulding is a high-volume, high tooling cost process, the advanced properties of our TPE compounds deliver short cycle times allowing parts to be produced at a rapid rate. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information Settings Equipment Conventional injection moulding machine Compression set At least 2:1. Special screws with short sections and higher compression ratios (3:1 to 4:1) may be good at low screw speeds Shrinkage Between 1.0% and 2.5% depending on the grade, type of application and location of the gate. Moul

Request for a quote

HEXPOL TPE GMBH

Germany

In the extrusion process the TPE pellets are poured into a hopper are heated in the barrel and turned into a melt by this heat and shear. A screw carries the melted plastic through a shaped die to produce continuous lengths of shapes with the same profile, which are then cooled by air or water. Our TPE compounds are easily extruded into single and complex profiles. They can also be co-extruded with other materials to yield a part with both rigid and soft components. They exhibit improved profile flexibility. The SEBS compounds, with their saturated intermediate blocks, are very stable against thermal degradation. On the other hand, the SBS compounds degrade if overheated or if a screw with excessively high compression ratio is used. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information SEBS based materials Equipment Extruders used for polyolefines are best for TPE comp

Request for a quoteResults for

Generating sets - Import exportNumber of results

10 ProductsCountries

Company type