- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- functional testing

Results for

Functional testing - Import export

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

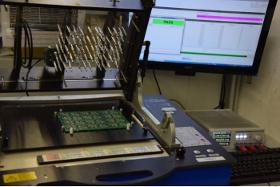

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. PRUFREX is a manufacturer of test systems and software. In close collaboration with our own test equipment developers, we manufacture beds of nails for the in-circuit test (ICT) and functional test (FCT), alongside test equipment and production aids. Using the entire range of available test procedures, we will develop a strategy that suits your product.

Request for a quote

BERATRONIC GMBH

Germany

Our services •Layout creation •Material procurement •SMD assembly •Manual and semi-automatic •Mounting •Reflow and wave soldering •Selective soldering •Automatic Optical Inspection (AOI) •X-ray inspection •System assemblies •In circuit tests and •Function test •Revision and repair •Rework Station •Short delivery times

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. This electrical test process is ideal for testing smaller numbers of units, such as for pre-production, prototype or pilot series. The rapid test creation process allows, among other things, flexible reaction to product changes. Flying probe tests can be rapidly set up and are cost-efficient.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Control Panels for electrical process heaters OhmEx has extensive experience in the design of heater control systems and requirements for ‘load splitting’. Loads can also be divided into stages to give thyristor control and in addition combinations of thyristor and contactor control can be supplied to provide a fully synchronised system and limit impact on the power generating system. We can recommend cost-effective solutions to clients, outline requirements, or work to detailed specifications. In-house design facilities are supported by experienced engineers, backed-up by modern CAD facilities. OhmEx adopts an integrated project management approach to each contract, which provides effective co-ordination of design, procurement, manufacture, test and, where required, commissioning. Attention is paid to ensuring that each system is built to the demanding standards of our client, the environment and current legislation. Each control system is fully function-tested for correct operation, as a standard. Each test is simulated using the correct type of input signals to avoid start up and commissioning problems. A range of temperature control systems suitable for anything from small space heating systems to large process heating systems, including full PID control can be offered.

Request for a quote

COMPUR MONITORS GMBH & CO. KG

Germany

New Gas Generator to check personal Gas Detectors A 100% Test in just 10 Seconds Personnel working in chemical plants protect themselves with personal gas detectors from gas exposure. Gas leaks are very unlikely to occur, so the gas detector will always display „0“. An instrument displaying zero can do so for two reasons: a) The concentration is zero. b) The instrument is defective. For good reasons a daily check of the instrument is mandatory. It would be too time consuming to perform a complete calibration every day. The daily functional test with the gas generator makes sure that no instrument failure caused by abuse or wear and tear will go unnoticed. To perform a test, it is sufficient to expose the sensor to a short puff of gas and see if the instrument gives an alarm. To make this test as fast, easy and cheap as possible, no accurate gas concentration is used, but approximately twice the value of the alarm threshold. The gas generator stops gas generation after 10 seconds automatically. If the detector fails to alarm within this time interval it is not safe to be used. The amount of gas produced when activated is very small. Therefore no restrictions regarding transportation and storage of the gas generator apply.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The PWT 101 is a testing device for the functional testing and adjustment of incremental and absolute HEIDENHAIN encoders. Thanks to its compact dimensions and sturdy design, the PWT 101 is ideal for portable use. Operation and visual display are performed on a 4.3-inch color flat-panel touchscreen. The PWT 101 supports a variety of functions depending on the encoder and the interface. With encoders featuring the EnDat interface, for example, you can display the position value, export online diagnostic data, shift datums, and perform further inspection functions.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quoteResults for

Functional testing - Import exportNumber of results

11 Products