- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control systems

Results for

Control systems - Import export

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements on process and quality monitoring and builds customised viscosity control systems for you. Viscosity control systems are mainly used for monitoring and optimising processes and product quality. In accordance with your needs IFA Technology implements complete plants which are equipped with mixing tanks, dosing units and consumption data acquisition. The viscosity sensors are used as rotation sensors, inline sensors or resonance frequency sensors, depending on the area of application. The connected controller is freely parameterisable and can be connected directly to higher-level control systems via an interface.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The coherent operating logic with integrated protection functions guarantee reliable operation of the boiler systems. — For intelligent control of multi-boiler systems and individual boiler systems — Easy connection to higher-level visualisation and control systems — Integrated monitoring and protection functions to prevent faulty operation — Extensive storage of operating parameters and operating signals — Secure remote access via MEC Remote — Intuitive operation with graphical symbols and state-of-the-art touchscreen displays

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Comprehensive monitoring and alarm functions enable you to react quickly as needed to ensure the reliable availability of heating energy and process heat. — Convenient remote monitoring of your boiler system and access to all important operating parameters — Simply integrate the remote technology for connection via Internet or a company network — Fast and cost-efficient online support from Bosch experts on request — Safety first: Certified, multilevel security concept for your remote access — Automatic alarm notification by text message or e-mail as an option so you can react quickly when needed

Request for a quote

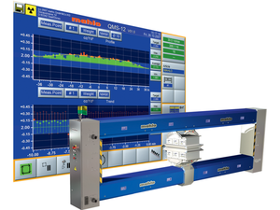

MAHLO GMBH & CO. KG

Germany

Web process control The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight, coating weight, thickness, moisture etc.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

Temperature is one of the most measured physical parameters. Despite this, precise temperature measurement is one of the most difficult tasks in motor technology. To meet the constantly increasing requirements for improved motor performance, higher efficiency and reduced emissions, it is necessary to use reliable and precise sensors in modern motor control systems. The increased requirements over the last few years regarding measurement accuracy and reliability of temperature measurements has meant that many equipment operators must reconsider the suitability and performance capacity of their temperature measurement equipment. Resistant thermometers can be used between -200 °C and +850 °C. An important common property is that their output parameters are available in the form of electric signals that can be relatively easily transferred to measurement and control instruments for processing, storage and display.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

What you can see is easier to understand. Therefore we visualise IFA Technology plants and systems with "WinCC", "WinCC Flexible", "WinCC TIA", "InTouch" or "Panelview". Special programs are also possible. These tools provide a reliable interface between the user and the machine (user interface) and allow a quick overview of the most important control parameters of the plant or system. The integrated error reporting system facilitates troubleshooting and reduces the time required for this to a minimum. Language toggling allows the operator to choose between different languages for the user interface.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

Automatically controlled systems In automated systems, parts are moved through the plant using a hoist in a fully-automatic, PLC controlled process. The bath parameters, the exposure time for parts in the baths, and the process steps are all saved in the PLC. The system runs through the process fully automatically. Operating personnel are primarily responsible for monitoring the system. Fully automated systems can significantly optimize manufacturing processes for small and large-scale series production through precision and economic efficiency (consumption quantities, energy management).

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

Manually controlled systems In manual systems, goods are moved through the system by hand or using a chain hoist. A hardware controller is used to set and monitor the individual bath parameters. Upon request, a small PLC can be installed for regulation and logging purposes. The electroplater sets the exposure time for the individual baths on each bath. The quality of the individual process steps, and therefore the parts themselves, is therefore greatly dependent on the precision of system personnel. Manual systems are used when semi- or fully automated operation would not be reasonable from an economic or technological standpoint.

Request for a quote

MANUFAKTUR VON DOBERSTEIN

Germany

Jumping jet systems produce spectacular computer-controlled water effects paired with exclusive lighting effects. The water jet rises from the opening and flies as cut on a predetermined parabolic orbit accurately in a small collecting opening. In this case, the transparent water jet is continuous or cut in different lengths representable. This can be the combine different water launch variants. Accompanied by state-of-the-art LED technology, the jet of water appears to fly independently in a variety of variations. Jumping jet systems can be operated in the indoor and outdoor areas alike.

![Distillation Control System ILUDEST® [DC / MoS]²](/filestore/vig280/opt/product/ea/9a/distillation-control-system-dc-mos2_3ede0556.jpg)

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The use of a computeraided system is well suited for the control and regulation of distillation and rectification plants the wide range of measurement and regulating tasks, the need for flexibility, ease of operation and a display of the operating parameters make the use of a computer with the relevant software and peripherals appear the ideal solution.

Request for a quote

NORIS GROUP GMBH

Germany

The N3500 (NORIMOS 3500) is our cost-efficient alarm, monitoring and control system for engines and auxiliary systems. The system is based on two central, redundant PC master stations. They collect and monitor the measurement data from the connected I/O modules. With up to 9,000 I/Os, a matching alarm extension system for accommodation and a monitoring display for the bridge, the system can be easily extended and adapted to any application. The N3500 is based on robust components and can be used flexibly: from simple data acquisition systems up to complex alarm and monitoring systems with integrated control functions for pumps, valves and fans. The system is approved by all conventional shipbuilding classification societies (ABS, BV, CCS, DNV-GL) and thus, is the ideal companion for all aspects of the monitoring and control of shipboard propulsion systems.

Request for a quote

NORIS GROUP GMBH

Germany

NORIMOS 4 – The High Performance PLC-based Alarm, Monitoring and Control System The N4 is our alarm, monitoring and control system (AMCS) for highest demands in operating comfort, usability, flexibility and system availability and is based on our NORISYS 4 open automation platform. It is used to monitor and control ship technology, such as engines and other auxiliary systems. The N4 is a PLC (IEC 61131) based AMCS with decentrally placed subsystems. Each subsystem is operating independently with a high performance I/O CPU master and its slave units and is connected to the other subsystems. The system is based on extremely robust components, can be used flexibly and furthermore, it can be extended with a comprehensive package of standard functions on request: whether as a simple data acquisition system, alarm and monitoring system, with additional control functions for pumps, valves and fans, or even fuel level measurement or power management.

Request for a quote

NORIS GROUP GMBH

Germany

NORISTAR 4 - The flexible remote control system for all propulsion drives The NORISTAR 4 is our powerful remote control system (RCS) for all types of ship, whether tugboats, cargo ships, passenger ships or super yachts. It is based on our NORISYS 4 open automation platform and is suitable for all propulsion drives. The system can be configured for multiple control consoles and offers many useful functions, such as load distribution, preprogrammed control programs, "electric shaft" function, start/stop logic, DP and joystick function. Configuration and monitoring are performed in a simple and user-friendly way via an integrated touchscreen display. Optional web access makes service easier and facilitates remote maintenance and the transfer of data to fleet management.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D2892/5236 CC or FISCHER® AUTODEST® 800/860 AC is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. Fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector (in the system section TBP with 20 receivers) includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The automatic fraction collector (in the system section Potstill with 12 receivers) includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC can be converted to the “HV” version by adding an extended Potstillcolumn to the standard ASTMsystem (Potstill). The respective distillation process is performed in the range of 0.005...0.1 mm Hg. The iFischer® DIST D5236 HV 6 ltr / FISCHER® AUTODEST® 860 HV 6 ltr is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. The system is also available with a capacity of up to 50 ltr.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Also available are the iFischer® DIST D5236 CC 50 ltr, 100 ltr, 150 ltr and 250 ltr fully automated computerised distillation systems acc. to ASTM D5236 equipped with a set of comprehensive safety features in correlation with the applicable EU Machine Directives and refinery standards. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The system is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. It is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 20 receivers includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Numerous optional items available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

For many years now, the MANUALplus has been proving itself in daily use on cycle lathes and is characterized particularly by convenient manual machine operation. Application-oriented cycle programming enables the machinist to create and edit programs rapidly and effi ciently on the lathe. The introduction of the MANUALplus 620 extends the area of application to single-spindle CNC lathes. With the smart.Turn operating mode, HEIDENHAIN has made yet another step forward toward greater ease of use. Easily understandable program entry in forms, default setting for global values, selection options and straightforward graphic support ensure fast and easy operation. The new smart.Turn interface is based on the proven HEIDENHAIN DIN PLUS: smart.Turn creates DIN PLUS programs and provides both the NC programmer and the machine operator with all relevant information during program run.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Thanks to its flexible operating concept – workshop-oriented programmability with HEIDENHAIN conversational programming or external programming – and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for series and single-part production tool and die making manufacture of machines research and development prototype production and testing facilities repair departments educational and training institutes The TFT 15-inch color monitor shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control such as program blocks, comments and error messages. More information is provided through graphic support during program entry, test run and actual machining. The selectable split-screen display shows the part program blocks in one half of the screen and the graphics or the status display in the other half.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling and boring machines, as well as machining centers. While the controls have undergone continuous development during this period, the basic operational technique has remained the same. You will find also these principles implemented in the TNC 640, the HEIDENHAIN contouring control for milling and milling/turning operations: shop-oriented programmability with graphic support, many field-proven cycles and an operational design you'll recognize from other HEIDENHAIN controls. Shop-oriented programming You program conventional milling and drilling operations, and with the TNC 640 also turning operations, yourself at the machine, in plain language dialog—the workshop-oriented programming language from HEIDENHAIN. The TNC 640 provides you with optimum support with practical prompts, questions and expressive graphical aids—for turning operations, too.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For many years now, the CNC PILOT has been proving itself in daily use on lathes and has earned a reputation for convenient NC programming. With the introduction of smart.Turn, HEIDENHAIN has made yet another step forward toward greater ease of use. Easily understandable program entry in forms, default setting for global values, numerous selections and straightforward graphic support ensure fast and easy operation. The new smart.Turn interface is based on the proven HEIDENHAIN-DIN PLUS. Because smart.Turn produces DIN PLUS programs. It provides both the NC programmer and the machine operator with all relevant information during program run. Thanks to its flexible design and numerous programming features, the CNC PILOT always gives you optimum support. Regardless of whether you are manufacturing single parts or batches, simple or complex workpieces, the CNC PILOT always provides the right support. The CNC PILOT is characterized by its simple operation and programming.

Request for a quoteResults for

Control systems - Import exportNumber of results

22 ProductsCompany type

Category

- Numerical control systems - minicomputers and mainframes (5)

- Water extraction - systems and equipment (5)

- Automation - systems and equipment (2)

- Boilers, industrial (2)

- Goods handling systems, continuous (2)

- Electronics - ships (1)

- Fountains, street and park (1)

- Temperature sensing devices (1)

- Weight and mass - measurement and regulation instruments (1)