- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- motor operated

Results for

Motor operated - Import export

IGUS® GMBH

Germany

dryve motor control - connect & control... Operate DC motors wear-free in left/right rotation - very easy with the new control for drylin® E drive systems from igus®. drylin® D5 for DC motors -Ready for immediate use. No parameterization or programming necessary - Left/right run via digital input - Velocities & accelerations via external PWM input signal - Available with and without housing - Inexpensive - Free pattern programs

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

With our trusted separator system, suitable for up to 29,000 residents at a system power of 600 m3/h. The base version, the AWALIFT 9/4, achieves a discharge head of 40 mWS, and the expanded version AWALIFT 9/4x2 achieves 80 mWS. Smart pump controllers are available as accessories, and are specially adapted to your system and your specific needs. The impellers are adapted to the operating point to achieve optimal performance. Draining towns with up to about 29,000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with four separator systems Four centrifugal pumps and motors according to type and operating location required Eight pump gate valves Four STRATE non-return valves One Y-pipe DN 300 Four pressure pipe gate

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

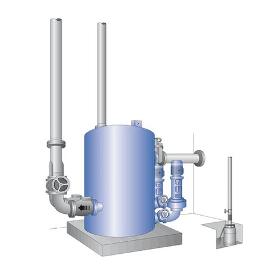

With a diameter of 2.5 m and a height of 3 m, the tank and separator system is equipped to reliably drain wastewater for a small city of up to 18,600 residents. In addition, the tank offers a gas and odor-tight seal. Three pumps provide good operational reliability; maintenance work is easy to complete thanks to dry installation. Draining towns with up to about 18,600 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with three separator systems Three centrifugal pumps and motors according to type and operating location required Six pump gate valves Three STRATE non-return valves One Y-pipe DN 250 Three pressure pipe gate valves DN 250 Level measurement

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 4/2 achieves a discharge head of up to 55 mWS, and is also available in the AWALIFT 4/2x2 version. This variation achieves a discharge head of up to 110 mWS. An opening of just 2 x 2 m is required for installation; once installed, the exterior dimensions of the system are 4.5 x 3.5 m. Different motor variations allow the system to be precisely adapted to your particular needs. The impellers are adjusted to the specific requirements. Draining towns with up to about 5600 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system. Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 150

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor-type vertical spindle machining center. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of aluminium, PVC and steel sections. The work pieces are held by means of 4 pneumatic vices on the mobile beam, that can be positioned on any angle between +125° and -125°. The rotation is directly managed by the control cycle. It offers a high programming functional capacity by using a three-dimensional graphics software. Electro-welded base designed to grant maximum rigidity and functional capacity of use. The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The vices slide on ball recirculation screws, and can be positioned manually by referring to a mm-scale and a laser pointer. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be performed with...

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

PRESSTA EISELE GMBH

Germany

5 axis CNC floor type vertical spindle machining center. 5 axis (X, Y, Z, C, A) managed by CNC. Suitable for milling, drilling, tapping and cutting on the 5 sides of aluminum, PVC, steel and light alloys profiles; thanks to the 5 axis interpolation, the machine is able to execute composite cuts. The X or longitudinal axis, the Y or transversal axis and the Z or vertical axis belong to the tool movement. They can be interpolated in linear and circular way on 3-dimension geometrical planes, belonging to X-Y-Z. The C axis can be turned and positioned on all angles within 440° (± 220°); the A axis can be tilted and positioned on all angles within 250° (± 125°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be...

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

An especially large system with six pumps and a tank content of 26.0 m3, a system power of 800 m3/h and a weight of approx. 6.3 t can reliably handle drainage for a city with up to 37,000 residents. The unique pump controls achieve a discharge head of 40 mWS, while the AWALIFT 10/6x2 version boosts this discharge head to 80 mWS. Proven components, such as our separator, separating flaps, level controller, etc. are used in this system as well. Draining towns with up to about 37,000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with six separator systems Six centrifugal pumps and motors according to type and operating location required Twelve pump gate valves Six STRATE non-return valves One Y-pipe DN 300

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

With a system power of 250 m³/h, the AWALIFT 6/3 achieves a discharge head of 48 mWS. The AWALIFT 6/3x2 version allows for a discharge height of 96 mWS. The fully automated, floodable STRATE AWALIFT system fulfills the requirements of DIN 1986-100 and DIN EN 12056-4. Draining towns with up to about 11,600 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with three separator systems Three centrifugal pumps and motors according to type and operating location required Six pump gate valves Three STRATE non-return valves One Y-pipe DN 200 Three pressure pipe gate valves DN 200 Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

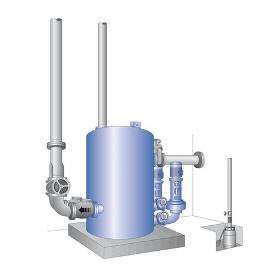

The AWALIFT 6/2 is designed for up to 9,300 residents, and is able to provide drainage for small towns. The proven separator system is also used in this size, and the systems are installed dry. System operation and maintenance are very user-friendly. The pump controls are designed according to the user's needs and mounted in an external cabinet. Additional accessories are available for this system, please submit your inquiry. Draining towns with up to about 9300 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 200

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 5/2 achieves a discharge head of up to 50 mWS, and is also available in the AWALIFT 5/2x2 version. This variation achieves a discharge head of up to 100 mWS. Different motor variations allow the system to be precisely adapted to your specific needs, and the impellers are adjusted to the operating point. This system is used for drainage in towns with up to 7,000 residents. Draining towns with up to about 7000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system. Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 150

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

This sewage pumping system can be used for districts with up to 3700 residents and it offers a discharge head of up to 80 mWS. The expanded version, the AWALIFT 3/2x2, even offers a discharge head of up to 120 mWS. Accessories, such as a smart pump controller, a basement drainage pump, pipelines and a variety of flanges within a single building, and much more are available for purchase on request. Draining small towns with up to about 3700 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 125 Two pressure pipe gate valves DN 125

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 2/2x2 wastewater pumping system is suitable for towns with up to approx. 2800 residents. The system can achieve a discharge head of up to 120 mWS, thanks to the parallel operation of two pumps. An adapted, intelligent pump controller handles control, ensuring almost fault-free operation. Draining small towns with up to about 2800 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems 2 x 2 centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 100 Two pressure pipe gate valves DN 100 Level measurement

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 2/2, with a system power of 60 m3/h raw wastewater, is suitable for towns with up to 2800 residents. The separator system offers a clean solution, since the container is gas and odor-tight. Different motor variations allow the system to be individually adapted to on-site conditions. AWALIFT systems can also move wastewater over long distances. Draining small towns with up to about 2800 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 100 Two pressure pipe gate valves DN 100 Level measurement

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Anywhere small quantities of wastewater need to overcome a high discharge head is the perfect application for the flattened version of the AWALIFT 2/2, with a shape that makes it a good space-saving option. It also offers our proven bulk materials collection system and is installed dry. The system controls are individually adjusted and installed in a switch cabinet outside of the shaft. Draining small towns with up to about 1700 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves Two pressure pipe gate valves DN 100 One Y-pipe DN 100

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 1/2x2 is used in many applications that require small quantities of waste water to overcome a high discharge head. With a capacity of 15 m3/h, the system is suitable for up to 750 EW. The system can be adapted to your individual needs through the use of different motor variations. Drainage of small towns with up to about 750 residents that cannot be drained using natural gradient. Drainage with larger pumping heads and longer pressure pipes As an intermediate pumping station within a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features The tank with two separator systems Four centrifugal pumps ST (M)65/80, motors according to type and operating location required Four pump gate valves One Y-pipe Two STRATE non-return valves Two gate valves Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 1/2 is used primarily in municipal applications for draining large properties. It is a fully automated, floodable sewage pumping system with a proven separator system for up to 750 EW. Alternating two pumps provides a high level of operational reliability. There is no need to provide reserve pumps. This system also has a gas and odor-tight tank, the surface of which is coated with high-quality corrosion protection. •Larger buildings, industrial companies, individual streets •Facilities that cannot be drained using natural gradient •As protection from backwater damage •Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with two separator systems Two rotary pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Y-pipe DN 100 Two pressure pipe gate valves DN 100 Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 0/2 double installation with proven STRATE system conforms to the requirements of DIN 1986-100 and DIN EN 12056-4. The installation forms a closed, gas and odor-tight system that fulfills the highest requirements for hygiene and safety. The system can also be installed directly in the basement; no excavation is required. If it is installed outdoors, however, using a STRATE AWALIFT shaft is recommended. Larger buildings, industrial companies, individual streets Where the reserve pump has to guarantee fail-safe operation e.g. in restaurants and public buildings Facilities that cannot be drained using natural gradient As protection from backwater damage Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Two pressure pipe gate valves DN 100

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 74/2 double installation provides improved operational reliability, since the pumps alternate to pump waste water (which has already been separated from bulk materials) from the separator. Bulk materials are first pumped into the pressure line, then the line is flushed with pre-cleaned water from the tank. Multi-family homes Where the reserve pump has to guarantee fail-safe operation e.g. in restaurants and public buildings Facilities that cannot be drained using natural gradient As protection from backwater damage Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with separator system Two centrifugal pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Two pressure pipe gate valves DN 100 Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 0/1 requires a space of just 1200 mm x 1200 mm or d=1500 mm. Thanks to its unique design, it can be installed in even non-standard installation areas. A variety of available motor power levels make it suitable for use in a wide range of applications. Multi-family homes Facilities that cannot be drained using natural gradient As protection from backwater damage Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 74/1 is used primarily for draining floors, multi-family buildings and properties above the backflow level in accordance with DIN 1986-100, e.g. for properties that cannot be drained via a natural slope. DIN EN12056-4 establishes the upper edge of the street at the connection point to the public sewer system as the backflow level. Two-family homes Facilities that cannot be drained using natural gradient As protection from backwater damage Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

LMF JDN Low Headroom Trolleys The trolley for areas where headroom is restricted Carrying capacities: from 0,5 t up to 6,3 t When only very low headroom is available we recommend the JDN-Ultra-Low Monorail Hoists. Standard Features State of the art by using JDN Air Hoists PROFI TI as well as a new driving motor Low-maintenance and low-wear operation of the motors by means of a reduction of components No additional motor lubrication required 2-step travelling speed Changeable track width * Advantages Able to negotiate curves Longer cross beams to improve the minimum headroom even with bulky loads Options Rack and pinion drive Spark-resistant package Offshore paint Energy Feeding Systems The energy can be fed by various different systems: Energy chain C-shaped rail Square rail Spiral hose Hose trolleys * Please contact us.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Servo motors in hydropower plants normally operate water hydraulically. These servo motors perform the functions of opening, closing and control of shutoff and regulating devices and must be able to maintain the setting position at any prevailing pressure.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 100 is the system preferred for draining storeys, houses and plots of land below the backwater level in accordance with DIN 1986-100, i.e. for properties that cannot be drained using natural gradient. DIN EN 12056-4 specifies the backwater level here as being the road surface of the connection point to the public sewage system. Single-family homes (e.g. toilet, shower, bath, sink, washing machine) Basement flat Party rooms in the basement Two-family homes Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

GSW SCHWABE AG

Germany

Strong plasmaburned back plate provides smooth and straight operation Removable and adjustable hub disk Fast and precise expansion via bevel gear with exceptionally wide ranges, allows clamping of all internationally common coil sizes LH Series PullOff Reel with manually adjustable brake LHM Series Payoff Reel with threephase motor for start / stop operation LHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic hold down arm Electropneumatic brake system Larger mandrel segments Conical mandrel Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Crank expansion via directionally stable joints, easily operable even under weight Highestquality arbor with maintenancefree bearing and minimal deflection Boxshaped stand with welded base plate for great stability LMH Series PullOff Reel with manually adjustable brake LMHM Series Payoff Reel with threephase motor for start / stop operation LMHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic hold down arm Electropneumatic brake system Larger mandrel segments Conical mandrel Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Crank expansion via directionally stable joints, easily operable even under weight Highestquality reel arbor with maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability MH Series PullOff Reel with manually adjustable brake MHM Series Payoff Reel with threephase motor for start / stop operation MHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Hydraulic expansion Hydraulic coil car Auxiliary drive Traveling feature w optional automatic centering Larger mandrel segments Different mandrel heights Fullsize back plate Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quoteResults for

Motor operated - Import exportNumber of results

51 ProductsCountries

- Germany (51)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (12)

- Bremen and region (1)

- Frankfurt am Main and Hesse (1)

- Hannover and Lower Saxony (21)

- Kiel and Schleswig-Holstein (2)

- Magdeburg and Saxony-Anhalt (1)

- Mainz and Rheinland-Pfalz (4)

- Munich, Nuremberg and Bavaria (2)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (5)

Category

- Water - production and distribution (19)

- Metal straightening machines (6)

- Centrifugal pumps (2)

- Electric motors - dC (2)

- Lifting equipment - accessories (1)

- Electric transformers, converters and rectifiers (1)

- Grinding - steels and metals (1)

- Industrial sheet metal work (1)

- Measurement - Equipment & Instruments (1)

- Metal industrial presses (1)

- Metalworking hand tools, non-power (1)

- Plumbing, industrial (1)

- Robotics (1)

- Sealing rings (1)

- Submersible pumps (1)

- Urban fixtures and installations (1)