- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wood chips

Results for

Wood chips - Import export

SFK PLY GMBH

Germany

High-quality waste products (By-products) from our plywood production! With our extensive range of waste products, you can conserve resources while benefiting from high-quality wood materials. Birch-chips

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The RATIOTOP smoke generator offers unbeatable flexibility at very low wood chips consumption. The freely selectable smoke stages from slight to intensive smoke enable you to customise the aroma, preservation and colouration to your specific product's needs. No matter if you produce broiled sausage or darkly smoked goods The RATIOTOP has good reasons for being the smoke generator that sees the most use worldwide.Short smoking times by quick production of highest smoke concentration Variable smoke intensity Diverse smoke aromas and colour nuances TOPs available in the control Best, uniform product quality in colour and flavour Low costs, economic consumption of smoking material The grain size of the wood chips is 4 – 12 mm (KL 2/16) Automatic cleaning aid

Request for a quote

NISSHA EUROPE GMBH

Germany

Our biodegradable jars are ready for manufacturing in Germany and in Japan. We have two different mateial grades, 'Premium' and 'Universal'. 'Premium' material which contains visible wood chips adds natural and luxurious look to our customer's product., while 'Universal' material with smaller wood chip inside gives smooth texture and fits well with our customers' brand image. 4 different size jars(7ml, 9ml, 133ml and 200ml ) are currently available for dry and oily foods such as supplement and chocolate. 150ml jar is going to be availabel in 2022 Q1. <Feature> ・100 % plant-based material ・9 standard colour available ・Industrial compostable and free from microplastics (EN13432) ・Food Safety Material (Regulation (EU) 10/2011) ・Natural and luxurious look ・Custom designed product available upon request In additon, we can provide logo printing and liners for better sealing.

Request for a quote

NISSHA EUROPE GMBH

Germany

Our biodegradable jars are ready for manufacturing in Germany and in Japan. We have two different mateial grades, 'Premium' and 'Universal'. 'Premium' material which contains visible wood chips adds natural and luxurious look to our customer's product., while 'Universal' material with smaller wood chip inside gives smooth texture and fits well with our customers' brand image. 4 different size jars(7ml, 9ml, 133ml and 200ml ) are currently available for oily and powder cosmetics such as balm and shea butter oils. 150ml jar is going to be availabel in 2022 Q1. In addition, 60ml new jar just became available for water-based cosmetics. <Feature> ・100 % plant-based material ・9 standard colour available ・Industrial compostable and free from microplastics (EN13432) ・Natural and luxurious look ・Custom designed product available upon request In additon, we can provide logo printing and liners for better sealing.

Request for a quote

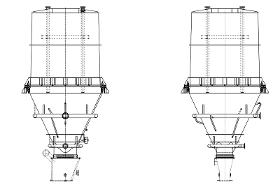

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR VARIOUS INDUSTRIES AND A VARIETY OF APPLICATIONS LIPP bulk silos are being used from a variety of industries and companies for different applications. Since decades, LIPP silos are used for the storage of grain in flower mills or as storage for animal feed in the agricultural sector. Also the furniture and wood industry is using LIPP silos to store wood chips or saw dust. ADVANTAGES OF LIPP BULK STORAGE A growing application is the storage of pallets for biomass plants. Different manufacturing companies are using LIPP bulk material silos as storage of buffer for their raw materials. The enhanced stability coming from the Double Fold System allows to construction of silos with big diameter and height ratio, with free carrying roofs as well as a fast filling and extraction. The silos can be built in closed manufacturing halls or building, very narrow installation sites and on high steel or concrete structures.

Request for a quote

AMROC GMBH

Germany

Composition of the cement board Amroc-Panel (A2-s1,d0): approx. 75% wood chips (100% PEFC) approx. 23% special cement approx. 10% water content contained in the wood chips approx. 2% binder

Request for a quote

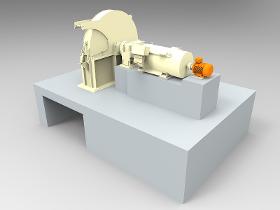

RUF MASCHINENBAU GMBH & CO. KG

Germany

The newly developed RUF Briklet press produces briquettes with a diameter of 30mm. The Briklet is the right choice, when a small briquette size is needed. Therefore they can be conveyed with an automatic feed. Furthermore, it automatically offsets varying grain sizes so that other materials apart from wood can be processed effortlessly. With wood chips, the RUF Briklet press can achieve a throughput rate of around 300 kg/h with a briquette density of ≥ 1 kg/l.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF SZ1+ briquetting system presses loose wood chips into compact briquettes. The high pressure ensures a constant high quality and density. As an entrylevel model of our wood presses, the SZ1+ is available in a standard design with proven RUF technology for small capacities (30 – 60 kg/hour). Benefits: Compact design Low wear Plug-in ready at delivery Easy operation with touchpanel Wide spectrum of additional compressible materials (wood, paper, styrofoam, ...) Automatic feeding of briquettes to industrial combustion plants possible

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF briquetting systems of the Biomass series process dust, shavings and wooden chips into briquettes of consistently high quality and density. Varying bulk densities are offset automatically during the process. These materials can be pressed into a compact form without the use of binders. It is important that the moisture content of the chips is below 15%, preferably under 12%, and that the chip size does not exceed 50mm. The general rule is that the finer the material is, the smoother and more solid the surfaces and edges of the resulting briquette. The systems can be equipped with a multitude of options, thus optimally adapting them to customer needs. This series offers maximum flexibility. All systems are extremely energy efficient thanks to the innovative RUF hydraulic system. Depending on the model, the machines are equipped with motors ranging between 4 kW and 90 kW. The throughput capacities of the RUF Biomass presses range between 50 and 1,300 kg/h.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

For every need a suitable press: All briquetting systems of the RUF LIGNUM series process residual wood at a constantly high level of quality and density – from dust to wood shavings and coarse chips. The remaining water content must be less than 15% in order to create briquettes with consistent quality and thickness. For every requirement the right format: The rectangular briquettes can therefore be perfectly stacked and bundled into packages . The briquette formats 150x60mm and 40x70mm are available. Optimized throughput rates with our LIGNUM series: All RUF LIGNUM models are highly energy effi cient thanks to their innovative RUF hydraulic system. The further improvement of the hydraulic system of the LIGNUM R2 and LIGNUM R4 has led to an effi ciency increase of around 25%. Briquetter for wood have depending on model & material throughput rates between 410and 1,050 kg/hr.

Request for a quote

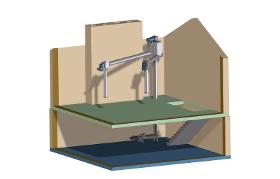

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Heating technology with a future The calculation is simple, the technology successful. Efficient surface drying is achieved with biomass in Rippert plants. Together with the Hargassner company from Austria, a specialist for heating with biomass, and the proven Rippert plant know-how, the technology is now marketable and has gone into production. The demanding drying characteristics in a powder-coating plant are compatible with the process and work perfectly. A future-orientated heating technology with considerable economic and ecological benefits – the experts are unanimous in that. Wood pellets or wood chips are the inexpensive energy suppliers. They are valuable waste products that result from the processing of domestic timbers. Heating with wood chips – without intermediate heat transfer media such as thermal oil • Environmentally friendly and CO2-neutral • fully automatic boiler cleaning and ash discharge Maximum financial saving potentials are realised with this energy carrier. Wood chips, chopped to a transportable size and dried by the supplier, are stored in the storeroom near the plant. It can be located on the same level or lower. A tried-and tested transport system consisting of a floor agitator with springs and discharge auger carries the wood chips reliably into the plant. Here it acts as a fuel with maximum convenience. If the calorific value equivalents are examined, we see that 1,000 litres of fuel oil is equivalent to 12 m³ of wood chips. The ratio is the same for 1,000 m³ of natural gas. Heating with wood pellets - without intermediate heat transfer media such as thermal oil Wood pellets are true energy bundles. They consist of natural wood and are made by compressing sawdust, which is produced in large quantities every day in the industry. As a biomass they are the alternative to wood chips and are just as advantageous from an economical point of view. Pellets have the smallest volume and are conveyed dust-free and without odours from storage containers to a storage vessel next to the plant. They are transported into the combustion chamber via a rotary vane feeder and feed auger. For comparison: 1,000 l fuel oil = 2 t pellets 1,000 m³ natural gas = 2 t pellets 1,000 l liquefied gas = 1.32 t pellets Advantages • Reduction in energy costs Heating cost comparison (reference = 1,000 l fuel oil)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Industrial Grate-ring systems are used very often in processes involving energy generation with solid fuels. Büttner's grate-ring energy systems are individually customized to the operator's needs and are exible when it comes to the fuel needed – whether it be waste wood, bark, or chips. Key features: fuels with a moisture content level between 20 - 150% based on bd combustion of waste wood (A1 - A3), wooden board wastes (MDF, PB and OSB), bark, wood chips, co air-cooled step grate sized from 12 to 90 m² ring capacity from 10 - 100 MW automatic de-ashing system graduated air-inlets low emissions

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The first examples of which were built by CMC TEXPAN in the early 1990s.They are aimed at cleaning the material ow fed into the machine byremoving any possible contaminants, the density of which is higher than that of the processed wood chips, e.g. stones, sand, metals, rubber, coarser chipsetc.The principle of operation is based on densimetric separation chieved in a vibratory box. In addition to the vibration of the machine casing, the materialow is subjected to a strong, pulsating air ow, enhancing the separationeect and providing for further “dry leaning” of chips. Heavy contaminants (e.g. stones, glass, rubber and plastic) are removed from the material ow,discharged from the machine side and conveyed to further re-classication,while clean chips are discharged from the machine’s front end.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with lling level control, to a subsequent conveyor. Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Features, Function Chip length 20-25 mm Chip width 4-10 mm Options Adjusting devices for rotor and stator Knives

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Drum chippers are used to process long and short logs, wood pieces, saw mill waste, veneer waste, residual wood, and other wood waste to high-quality chips. Depending on the size and design of the drum chipper, the machine can be adjusted to the type of wood to be processed and the desired chip quality. The most suitable chipper size is determined by the maximum trunk diameter to be processed and the desired production capacity. The desired chip length also inuences the performance of the chipper. Key features Adv Large draw-in rollers for process-reliable wood feed at constant speed Pivoting feed system for automatic adjustment to loading height Hydraulic ywheel drive for consistent contact pressure and the damping of impacts Robust, well-balanced rotor Large ywheel inertia to compensate for short-term peak loads Generously dimensioned V-belt drive Startup process via Pony-motor to reduce spikes in power supply during acceleration of the rotor

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function The newly developed “EcoDrain Unit” allows the dewatering degree of wood chips in the plug screw to be increased. A newly designed dewatering zone allows for easy exchange of the wear parts. Advantages Payback after approx. 6 months All plug screw assemblies retrofittable Increased dewatering of the wood chips Energy savings in downstream processes Simple wear part exchange Low maintenance costs due to exchangeable wear parts

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function A high-performance chip bunker, which transports the most different feed materials trouble-free to the plug screw, is installed in front of the modern refiner plug screw assemblies. The new high-performance chip banker can be retrofitted to any Pallmann Refiner but can also be installed on machines from other manufacturers. Advantages Increased arrangement of the steam nozzles and more precise level monitoring for more effective presteaming of the wood chips Energy savings due to less boiling time of the wood chips Reduced bridging

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Hammer Mill, series PHMS is used for the economical preparation of wood chips from round wood, residual wood, waste wood or annual plants. The wood chips are of high quality and can be directly injected for combustion, or used as flakes for briquetting and pelletizing. Due to their quality they are also used for the production of core layer and surface layer material during the production of wood-based panels. Characteristics, Function Material is fed vertically from above The gravity sifter "Cleanomat" separates heavy contaminants from the feed material Flat steel hammers rotating at high speed split the feed material into flakes Stationary impact elements support the size reduction process and relieve the screens The perforation of the screens determines the size of the flakes The symmetrically designed machine housing allows operation of the mill in both directions Rotating flat steel hammers can swing back when large foreign objects penetrate into the grinding...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Hammer Mill, series PHMS is used for the economical preparation of wood chips from round wood, residual wood, waste wood or annual plants. The wood chips are of high quality and can be directly injected for combustion, or used as flakes for briquetting and pelletizing. Due to their quality they are also used for the production of core layer and surface layer material during the production of wood-based panels. Characteristics, Function Material is fed vertically from above The gravity sifter "Cleanomat" separates heavy contaminants from the feed material Flat steel hammers rotating at high speed split the feed material into flakes Stationary impact elements support the size reduction process and relieve the screens The perforation of the screens determines the size of the flakes The symmetrically designed machine housing allows operation of the mill in both directions Rotating flat steel hammers can swing back when large foreign objects penetrate into the grinding...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Hammer Mill, series PHMS is used for the economical preparation of wood chips from round wood, residual wood, waste wood or annual plants. The wood chips are of high quality and can be directly injected for combustion, or used as flakes for briquetting and pelletizing. Due to their quality they are also used for the production of core layer and surface layer material during the production of wood-based panels. Characteristics, Function Material is fed vertically from above The gravity sifter "Cleanomat" separates heavy contaminants from the feed material Flat steel hammers rotating at high speed split the feed material into flakes Stationary impact elements support the size reduction process and relieve the screens The perforation of the screens determines the size of the flakes The symmetrically designed machine housing allows operation of the mill in both directions Rotating flat steel hammers can swing back when large foreign objects penetrate into the grinding...

Request for a quote

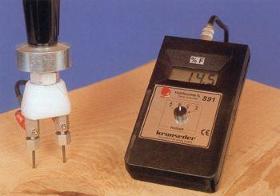

KRONSEDER TROCKENTECHNIK GMBH & CO. KG

Germany

Digital wood moisture measuring equipment We are not only specialists for wood drying, but also your partner to contact for anything related to moisture measuring technology. Our modern, innovative company combines moisture measuring technology, control technology Our digital moisture measuring equipment with temperature compensation accurately measures: Sawn timber, chipboard, veneer, sawdust, wood chips, wood shavings, concrete, aerated concrete, tiles, screed, plaster, silica sand (sand up to a maximum of 20 %), lime plaster, concrete, paper, cardboard and also textiles and drying technology into a complete coordinated offer.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Double Stream Mill, series PSKM is used for the fine preparation of precut wood chips and annual plants such as bagasse, miscantus, cotton stalks, hemp stalks, corn straw and rice straw. The fine flakes produced are characterized by their low percentage of dust and coarse particles. The areas in which the end material is used are diverse. It is used for energy generation, as insulation material, the reinforcement of building components and as raw material for the production of fine surface layers of particle boards. Characteristics, Function Compact and sturdy, designed for continuous operation Bearing- and drive system easily exchangeable as a complete unit A slide to remove the grinding ring is supplied as standard. Dismantling of the impeller is not necessary Material feeding via vibratory feeder and a feed chute designed as a gravity separator Even distribution of the material in the grinding chamber Size reduction is performed by repeated impact onto the impeller...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with filling level control, to a subsequent conveyor. Features, Function Chip length 20-25 mm Chip width 4-10 mm Chipping disc with large flywheel effect Robust, double-sided disc bearing Electro-mechanical locking during knife change Quick knife changes Re-grindable knives Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Options Adjusting devices for rotor and stator knives

Request for a quoteResults for

Wood chips - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Wood veneer - machinery and equipment (3)

- Woodworking - machinery and equipment (3)

- Hydraulic equipment (2)

- Wood chips and sawdust (1)

- Bottles and jars, plastic (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Cosmetics (1)

- Energy - production plants and equipment (1)

- Fibre-cement - products (1)

- Presses, hydraulic (1)

- Tanks, metal (1)