- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded pipes

Results for

Welded pipes - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust flat-panel detector was specially designed for mobile use and the harsh conditions of industrial radiography and can be used with X-ray and gamma sources. With its active area of 23.0 x 28.8 cm, excellent contrast and uniquely high resolution thanks to a pixel pitch of 75 µm, even the most demanding inspection tasks can be mastered. - Weld seam inspection - Pipe inspection, corrosion inspection, erosion inspection - Crack detection - Casting inspection

Request for a quote

ORBITEC GMBH

Germany

Our latest series of gas-cooled and compact weld heads. They are for smaller outside diameters with a narrow handle for tighter access conditions. Weld head type \ Field of application mm \ inch \ weight OSK 21 CS \ OD 3.17 - 21.3mm \ 0.125" - 0.839" \ 0.8kg OSK 38 CS \ OD 3.17 - 38.1mm \ 0.125" - 1.500" \ 1.2kg —-- Our new generation of compact weld heads for high duty cycle requirements have watercooled clamp housings and clamping levers. Both OSK CW weld heads are operated using a sharable handle and cable assembly. Weld head type \ Field of application mm \ inch \ weight OSK 21 CW \ OD 3.17 - 21.3mm \ 0.125" - 0.839" \ 1.0kg OSK 38 CW \ OD 3.17 - 38.1mm \ 0.125" - 1.500" \ 1.4kg Only one drive unit is needed for all C and CW weld heads. —-- OSK 21 CB gas-cooled weld head with clamping block for tube-totube connectons incl. setting gauge for pipe Weld head type \ Field of application mm \ inch \ weight OSK21 CB \ OD 3.17 - 21.3mm \ 0.125" - 0.839" \ 1.0kg

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flow Sight Glass Type Type N880-SOW with pipe – socket – weld connection Use: The flow indicators are used for optical control of fluids and gases, for horizontal and vertical pipe-lines. Also available with internal spinner or flap.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Clamps directly on straight copper pipes ! Double seal construction withstands a vacuum of up to 1.3 x 101 Pa. Clamps direct on to a straight copper pipe eliminating unnecessary welding or flaring. Withstands a vacuum of up to 1.3 x 101Pa (when connected) making it possible to be used in leak testing, evacuation and refrigerant gas charge. Select from three standard types of seal materials to be used with fluids for air conditioner and refrigerator production lines. Many models to suit various pipe sizes. One lever operation simultaneously clamps and seals pipe. Double seal construction for tight fit on end and outside surface of pipe ensures excellent sealing and vacuum resistance.

Request for a quote

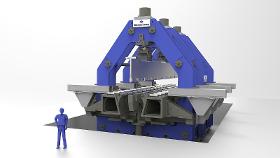

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - Ideal for conducting liquid and gaseous media as well as acids and lyes* - Also outstanding for absorbing lifting movements, such as on the covers of annealing and electric furnaces - And also as a compensator to absorb slight vibrations and noise Hose design - Normal corrugated Full metal hose made of butt welded pipe - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: STDA: AISI 316L, STD: AISI 316Ti - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at customer request * Please refer to our resistance...

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - As high pressure hose at particularly high pressure levels for conducting steam, water, oil, compressed air and oxygen - For carrying aggressive media Hose design - Normal corrugated Full metal hose made of butt welded pipe, Heavy duty - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: HDA: AISI 316L - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at customer request * Please refer to our resistance list in the download area

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - Ideal for conducting liquid and gaseous media as well as acids and lyes* - All applications which require the smallest possible bending radius and our hose type “Standard” cannot be deployed due to its larger bending radius - This type is also particularly recommended for use as a double hose line Hose design - Tight corrugated Full metal hose made of butt welded pipe - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: HFA: AISI 316L, HF: AISI 316Ti - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at...

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

The top tier of aesthetic and technology: With their flawless welding seams and trademark look, the KASPAR SCHULZ tanks are convincing in every aspect of brewery plant manufacturing. Thanks to our in-house only production, we can offer you customized plans that precisely tailor the tank measurements to the room height in your facility. The tanks are suitable for all types of beer, plus carbonated non-alcoholic and mixed beverages given that they are principally manufactured for a 3 bar operating pressure Ideal cleanup thanks to rounded manholes Temperature measurement using a contact sensor The bung apparatus (pressure regulator) can be integrated into the tank cleaning circuit without disassembly Welded and ground surfaces create an attractive appearance All piping is mounted mechanically (thus, without a welding arc). Piping is curved and therefore meets the highest biological safeguard requirements Minimal installation costs thanks to pre-piping

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

KURO cable protection pipes made of unplasticised PVC-U are ideal for the pressure-free underground installation of power and telecommunications cables. They also ensure perfect protection against all kinds of mechanical damage when used as cable protection pipes. HERE‘S HOW YOU BENEFIT: - Manufacture according to DIN 16873 and 8061/8062 - Advanced integral ring seal socket technology with permanent seal and long socket

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

The 20 kHz roll seam welding heads with up to 3KW power are particularly suitable for continuous welding of pipes, solar absorbers, or copper sheets. Thanks to the discshaped sonotrode, ultrasonic roll seams provide continuous welds without seam interruption.

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

The resistance thermometer with weld-in thermowell is suited for operation on tanks and pipes. Weld-in thermowells per DIN 43772 model 4 or custom-made versions are available. Because of its robust design it is suitable for use in a great number of technological processes. The resistance thermometer can be supplied with a built in transmitter. A variety of transmitters for head mounting is available for different applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

pipes (aluminium) - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.AL 38 x 1.5 FR.040.015.AL 40 x 1.5 FR.045.015.AL 45 x 1.5 FR.050.015.AL 50 x 1.5 FR.050.020.AL 50 x 2.0 FR.054.020.AL 54 x 2.0 FR.060.015.AL 60 x 1.5 FR.060.020.AL 60 x 2.0 FR.065.020.AL 65 x 2.0 FR.070.020.AL 70 x 2.0 FR.076.025.AL 76 x 2.5 FR.080.020.AL 80 x 2.0 FR.090.020.AL 90 x 2.0 FR.100.020.AL 100 x 2.0 FR.108.030.AL 108 x 3.0 FR.114.030.AL 114 x 3.0 pipes (stainless steel) - longitudinal seam-welded pipes - smoothed inner seam - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.CR 38 x 1.5 FR.040.015.CR 40 x 1.5 FR.045.015.CR 44.5 x 1.5 FR.050.015.CR 50 x 1.5 FR.054.020.CR 54 x 2.0 FR.060.015.CR 60.3 x 1.5 FR.060.020.CR 60 x 2.0 FR.063.015.CR 63.5 x 1.5 FR.065.015.CR 65 x 1.5 FR.070.020.CR 70 x 2.0 FR.076.020.CR 76.1 x 2.0 FR.080.015.CR 80 x 1.5 FR.080.020.CR 80 x 2.0 FR.084.020.CR 84 x 2.0 FR.085.020.CR 85 x 2.0 FR.089.020.CR 88.9 x 2.0 FR.100.015.CR...

Request for a quoteResults for

Welded pipes - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Metallurgy and iron and steel industry - machinery and installations (3)

- Temperature sensing devices (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Laser - cutting and welding machines (1)

- Agricultural machines and accessories (1)

- Air-conditioning systems, vehicles (1)

- Coupling, pneumatic (1)

- Fittings, pipe, tube and hose - plastic (1)

- Forming - steels and metals (1)

- Non-destructive tests (1)

- Pneumatic tubes - systems (1)

- Wine fermentation tanks (1)