- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded pipes

Results for

Welded pipes - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-round solution for process industries The OPTIFLUX 4000 has a field proven and unsurpassed lifetime. This is assured by the fully welded construction, full bore pipe construction, absence of moving parts and wear resistant liner materials. Even for demanding applications in harsh environments or with aggressive and abrasive media KROHNE’s OPTIFLUX 4000 can offer a solution. Examples include water injection under high pressures (2500lbs), subsea installations, slurries with very high solids contents, alkaline solutions and acids, up to chemical dosing, bleaching, coloring, and black liquor in the paper industry. If required, a solution beyond our standard scope can be engineered. KROHNE has in house specialized know how on constructions, welding and exotic materials

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

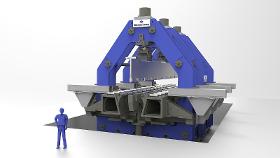

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - As high pressure hose at particularly high pressure levels for conducting steam, water, oil, compressed air and oxygen - For carrying aggressive media Hose design - Normal corrugated Full metal hose made of butt welded pipe, Heavy duty - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: HDA: AISI 316L - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at customer request * Please refer to our resistance list in the download area

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - Ideal for conducting liquid and gaseous media as well as acids and lyes* - All applications which require the smallest possible bending radius and our hose type “Standard” cannot be deployed due to its larger bending radius - This type is also particularly recommended for use as a double hose line Hose design - Tight corrugated Full metal hose made of butt welded pipe - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: HFA: AISI 316L, HF: AISI 316Ti - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at...

Request for a quote

IBK WIESEHAHN GMBH

Germany

Application - Ideal for conducting liquid and gaseous media as well as acids and lyes* - Also outstanding for absorbing lifting movements, such as on the covers of annealing and electric furnaces - And also as a compensator to absorb slight vibrations and noise Hose design - Normal corrugated Full metal hose made of butt welded pipe - Hose can be provided with no, one or two stainless steel braiding - Production according EN / ISO 10380 Material - Hose standard: STDA: AISI 316L, STD: AISI 316Ti - Braid standard: AISI 304 Temperature - From- 196°C up to max. + 600°C Also possible - With DVGW acceptance - CE sign as per the pressure equipment directive (97/23/EC) - As per DIN 2827 - With external Agraff or spirals to protect against abrasion - With internal Agraff hose or braiding as flow conductor - With flanged recoil lock - With PTFE inner lining - Special designs at customer request * Please refer to our resistance...

Request for a quoteResults for

Welded pipes - Import exportNumber of results

10 ProductsCompany type