- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibration sensors

Results for

Vibration sensors - Import export

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller. The device consists of an acceleration sensor, a controller unit and three types of output interface. The main feature is two safety switching contacts (potential-free), which can be used e.g. in the safety chain to undertake safety shut-off in the event of excessively high acceleration values. Data output is carried out via the CANopen interface. The standard or the safety profile can be selected. There are additionally two analogue outputs 4 ... 20 mA, which can be optionally assigned to two of the three measurement axes. Thanks to its high resistance to vibration and shock, the sensor is suitable for use in areas with rough environmental conditions.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller.The device consists of an acceleration sensor, a controller unit and the output interface PROFIsafe over PROFINET for output of the acceleration values. Thanks to its high resistance to vibration and shock - more than the defined measuring range -, the sensor is suitable for use in areas with rough environmental conditions.Electrical connection is carried out using three connectors.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller. The device consists of an acceleration sensors, a controller unit and three types of output interface. Data output is carried out via two analogue interfaces with 4 ... 20 mA plus CANopen and via 4 relay contacts (currently 1 error relay contact). The NVA is parameterised via the CANopen interface. This is not galvanically separated. The sensor is equipped with a filter circuit to protect against fast transients and surge voltages of up to 2 kV in the supply. The protection types are IP 69K (housing) and IP 67 (connector/socket). With its good vibration and shock values, the sensor is suitable for use in areas with rough environmental conditions.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

A micro-electromechanical spring-mass-system is continuously measuring the acceleration and transforms the measured data into an analog 4-20mA output signal. The sensor complies with the standards of DIN EN 50155 for railway vehicles. It is espacially intended to be used in the on-board network of rail vehicles. Its extrem rugged housing enables applications in harsh conditions in the outskirt area of the vehicle, directly at the bogie. The sensor impresses by its high ruggedness against impact, dust as well as moisture and guarantees high reliability. The device detects accelerations in a measuring range of ± 4g and operates with 24 Volt supply voltage.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

A micro-electromechanical spring-mass-system is continuously measuring the acceleration and transforms the measured data into an analog 4-20mA output signal. The sensor complies with the standards of DIN EN 50155 for railway vehicles. It is espacially intended to be used in the on-board network of rail vehicles. Its extrem rugged housing enables applications in harsh conditions in the outskirt area of the vehicle, directly at the bogie. The sensor impresses by its high ruggedness against impact, dust as well as moisture and guarantees high reliability. The device detects accelerations in a measuring range of ± 4g and operates with 110 Volt supply voltage.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

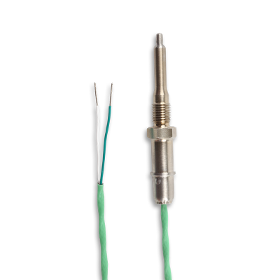

This sensor for measuring exhaust gases was developed together with a Formula 1 team. The goal was to achieve the greatest possible reliability during the race. The sensor was designed so that it can withstand a maximum of vibrations and extreme temperatures while being made in a highly compact construction at the same time. The special feature is the connection lead. It is not made from the usual mineral-insulated stainless steel sheathed line, which is too rigid and which tends to vibration fractures. Instead, the line is made of stranded conductors with PTFE insulation and an additional heat shield so it can be easily and flexibly adapted to the environment. The sensor is being used with exceeding success by professional teams in long distance races, American race series and the domestic DTM. The benefits: Highly vibration-proof Very robust High temperature resistance (up to 1,200 °C) Individual plug assembly possible Can be individually adapted

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This plug-in sheathing thermocouple is recommended for measuring the temperature in the exhaust gas flow. It is genuinely multipurpose, mounting with the cap nut means the thermocouple does not need to be rotated, which simplifies installation and fast replacement. In addition, it has “motor sports genes” such as vibration resistance, fast response time and high temperature resistance. The benefits: Vibration-proof Fast response time High temperature resistance (up to 1,200 °C) Various installation lengths can be supplied With cap nut Sheathed thermocouple NiCr-Ni, Type “K”, Class 1

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-performance spindles with an integrated motor are designed for those applications and relevant installation situations in close collaboration with our customers. They are available as needed with a synchronous or asynchronous motor, for manual - HGS series - or automatic tool change - HGC, HGT series - and with oil-air or grease lubrication. Additional options are, for example, an AE sensor, vibration sensor or an automatic balancing system.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Sensors of the family IGEX22 for use in zone 22 with integrated electronics and direct switching output to the non-explosive area do not need a separate analysis device. This saves space and costs. The EGE IGEX20 proximity switches are based on the conventional inductive principle and switch when a metallic object moves close. This family includes shock and vibration resistant solid stainless steel sensors. The sensors are certified according to ATEX and IECEx. The sensors of this family are suited in the area of explosive dust atmospheres (zone 22) for presence verification, position and movement monitoring and the counting of metallic objects and the speed control on conveyor belts.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Sensors and accessories for vibration measurement and Condition Monitoring Large selection of vibration sensors accelerometers, displacement sensors, VIBCODE transducer and triaxial sensors Accelerometers measure vibration acceleration, shock pulse (roller bearing condition) and pump cavitation Also available in compact size, for lowspeed machines and as combi sensors for vibration and temperature Patented tandempiezo technology eliminates the disadvantages of conventional sensors Highquality signal transmission over long distances up to 1,000 meters (3,200 feet) with current line drive (CLD) signal amplification Various mounting types EX / ATEX versions available Temperature probes, keyphasers, cables, adaptors and tools available

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The Fluke 3563 combines a highfrequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s productioncritical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required. The sensor’s LIVEAsset Portal software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical nextstep actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

VIBGUARD compact for individual assets VIBGUARD compact offers six measuring channels for continuous monitoring. It is perfectly suited for fast and highly dynamic equipment. In particular, the VIBGUARD compact meets the requirements of critical assets that are characterized by high availability, high aggregate values, complex drives and changing operating conditions. Whether preinstalled in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges. All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables.

Request for a quote

PULSARLUBE GMBH

Germany

Pulsarlube Mi automatic grease lubricator is innovatively designed to detect the operation of industrial rotational machinery by using a piezoelectric vibration sensor. This piezoelectric sensor is composed of a ceramic strain transducer attached to a metallic proof mass in order to respond to an externally imposed acceleration. Fully automated lube system Clear reservoir that is easy to see the remaining grease inside No need for external electric wiring to a motor or other power supplies Possible to choose proper high performance lubricants according to specific environments Reliable constant, precise & predictable lubricant supply Low maintenance cost, competitive with manual lubrication

Request for a quote

IPF ELECTRONIC GMBH

Germany

Inductive proximity switches are contact-free sensors. They detect all conductive metals, regardless of whether they move or not. The achievable sensing range of the devices depends on the object material and its dimensions. The vibration-resistant sensors can be approached laterally or frontally. Inductive proximity switches are used for presence detection (e.g. goods carriers), positioning (e.g. dampers), counting (e.g. nuts /bolts), speed detection (e.g. for cog wheels), on conveyor systems (e.g. hose feedings) or distance measurements (e.g. press-in checking) of metallic objects.

Request for a quote

IPF ELECTRONIC GMBH

Germany

Capacitive proximity switches are contact-free sensors. They detect metallic and non-metallic objects, regardless of whether they move or not. The achievable sensing range of the devices depends on the object material, its dimensions and the response sensitivity, which is set via a potentiometer. The vibration-resistant sensors can be approached laterally or frontally. Capacitive proximity switches are used for presence detection (e.g. sealing detection), positioning (e.g. PET bottles), counting (e.g. plastic caps), level detection (e.g. lubricant) or distance measurements (e.g. thickness measurement) of solid and liquid materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IPF ELECTRONIC GMBH

Germany

Inductive proximity switches are contact-free sensors. They detect all conductive metals, regardless of whether they move or not. The achievable sensing range of the devices depends on the object material and its dimensions. The vibration-resistant sensors can be approached laterally or frontally. Inductive proximity switches are used for presence detection (e.g. goods carriers), positioning (e.g. dampers), counting (e.g. nuts /bolts), speed detection (e.g. for cog wheels), on conveyor systems (e.g. hose feedings) or distance measurements (e.g. press-in checking) of metallic objects.

Request for a quote

IPF ELECTRONIC GMBH

Germany

Inductive proximity switches are contact-free sensors. They detect all conductive metals, regardless of whether they move or not. The achievable sensing range of the devices depends on the object material and its dimensions. The vibration-resistant sensors can be approached laterally or frontally. Inductive proximity switches are used for presence detection (e.g. goods carriers), positioning (e.g. dampers), counting (e.g. nuts /bolts), speed detection (e.g. for cog wheels), on conveyor systems (e.g. hose feedings) or distance measurements (e.g. press-in checking) of metallic objects.

Request for a quoteResults for

Vibration sensors - Import exportNumber of results

20 ProductsCountries

Company type