- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- straightening and cutting machines

Results for

Straightening and cutting machines - Import export

FÖHRENBACH GMBH

Germany

The straightening machine RM-1000 was developed for straightening deep-hole drills, as 4- and 6-axis version. The radial run-out of a drill is straightened using the 4-axis version. The 6-axis machine additionally corrects the camber of the shank and the head run-out of the soldered carbide drill bits. The maximum length of the drills is 1,000mm, the accuracy of the straightening process is 0.08 mm (depending on the work piece). An exportable straightening protocol is created for each straightening process. A robot cell is available as an option. Using this robot cell, the insertion and removal of the drills is performed. The robot cell is mobile and can be disconnected at any time in order to allow manual straightening processes.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

GSW SCHWABE AG

Germany

High quality, extremely simple operation, unreached price/performance ratio For decades, the GSW Straighteners are valued all over the world. The Straightener with clamshell head (the GSW “AlligatorHead”) came out in 1968 – the RMA series – and today is being built in up to 2000mm width. This machine levels coil set and equals out tension with up to 12mm thick materials. It has given GSW a pioneer’s position in the industry. The RMZ series Straighteners convince where high straightening and pull forces are needed. Its frametype head design provides a high stiffness and elevates this technology to work with high demands in straightening quality – even with highertensile materials.

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quote

ZINSER GMBH

Germany

High-precision plasma cutting machines from ZINSER - efficient cutting solutions for all applications ZINSER GmbH offers a wide range of high-precision plasma cutting machines that are known for their outstanding cutting quality and efficiency. Our systems are specially designed to cut mild steel, stainless steel and aluminum with the highest precision. Thanks to the latest technology and a robust design, our plasma cutting systems ensure maximum productivity and reliability in industrial production. ZINSER 4025B / 4125B / 4026B / 4126B These premium plasma cutting machines offer excellent cutting quality and reliability for demanding applications. They are ideal for cutting thick and thin materials and are suitable for both simple and complex cutting tasks. ZINSER 2315 / 2325 / 2425 / 2426 Our economical plasma cutting machines offer a cost-effective solution without compromising on quality.

Request for a quote

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

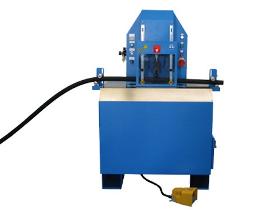

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 1 ¼”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The safe high-quality cutting machine for the production process. All cutting blades are made of carefully tested material which ensures optimum cutting quality. 7.5 kW drive max. For hydraulic hose assemblies up to 3” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Planetary cutting machine for corrugated metal and PTFE hoses. Cutting results that often eliminate an additional step. This completely unique planetary cutting machine delivers almost scrap-free production and high efficiency. With a completely variable centering clamp system, all hose OD to the maximum rating for the machine can be cut. Approximate cutting time is 25 seconds for 1 ¼“ (ø DN 32). Productive and ergonomic •No dramatic flaring of the stainless steel braid •Reduces or eliminates time-consuming manual preparatory work thereby increasing productivity and lowering costs •Centering hose clamp system •Shortest cut possible from 10 cm •Minimizes personnel costs and preparatory work •No wrapping/unwrapping with adhesive tape required •Clearly laid-out user friendly software on a panel with a 6“ color display screen •Large article memory promotes productivity •Reference run for optimal positioning of the cutting blade for cutting all hose diameters CE compliant

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Where pneumatic tools of the MBS series reach their performance limits, the eccentric cutting machine opens up new possibilities in cutting performance. Instead of a pneumatic cutting tool, the Metzner ST 25 uses an electrically driven eccentric mechanism that carries a punching blade. This enables us to increase the performance of the die-cut into completely new dimensions, of up to 800 cuts per minute. An agreeable side-effect: With the electric drive for the cutting tool, the ST 25 works very quietly – which is why customers with low-noise working environments also like to opt for this model.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

The Metzner CCM 2 circular cutting machine processes steel-reinforced profiles and sponge rubber materials with dry cutting (optionally with micro-knife moistening to cool the circular knife). The standard model comes with an integrated discharge conveyor (1300 mm length); range of application both in-line and off-line.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Request for a quoteResults for

Straightening and cutting machines - Import exportNumber of results

20 ProductsCountries

Company type