- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- straightening and cutting machines

Results for

Straightening and cutting machines - Import export

SCHNELL SPA

Italy

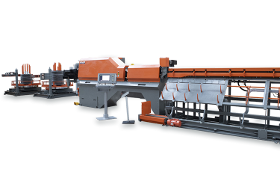

Automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4). Driven by digital electric servomotors. Capacity 2 Ø 10 mm (#3) Max pulling speed 150 m/min (495 ft/min) Straighteners with independent position and adjustment displays for the wires Cutting with Brushless Motorized wire change unit Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 6inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 5inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Multirotor wire straightening machine using coils up to Ø 20mm for the production of straight bars. 4 wheel drive pulling unit driven by servomotors for high speed production; Maximum pulling speed 140 m/min; The straightening system uses rotors, each one dedicated to a single bar diameter which guarantees perfectly straight bars and wire diameter changes in just a few seconds; Servomotor driven cutting unit guarantees high speed and high cutting accuracy; Twin Version (Optional) with double cutter, double channel, double pulling unit it allows the processing of two bars simultaneously, doubling the productivity of the machine. Lista Bar wire straightening and cutting machine can be equipped with Bundle aligning device on the ground with vibrators (Optional); Indexing carriage for the automatic collection and sorting of the bars produced (Optional); Storage rack pneumatically operated (Optional).

Request for a quote

TECNO IMPIANTI SRL

Italy

STRAIGHTENING AND CUTTING MACHINE Model EvoCUT6012 The new Tecno Impianti straightening & cutting machines model EvoCUT are a concentrate of strength, technology and design. They are used for straightening and cutting of smooth wires made of mild steel, stainless steel, brass, copper, bronze etc.; for the latter ones, we have developed tooling with specific geometries and materials. The use of brushless servomotors and very high quality planetary gearboxes for the management of the axes ensure an excellent performance in dynamic, dimensional and quality terms on the finished product. Proportional valves for pressure control allow the operator to store the settings regarding pulling and position transducer for each single application, ensuring the constancy of the set values over the time.

Request for a quote

FÖHRENBACH GMBH

Germany

The straightening machine RM-1000 was developed for straightening deep-hole drills, as 4- and 6-axis version. The radial run-out of a drill is straightened using the 4-axis version. The 6-axis machine additionally corrects the camber of the shank and the head run-out of the soldered carbide drill bits. The maximum length of the drills is 1,000mm, the accuracy of the straightening process is 0.08 mm (depending on the work piece). An exportable straightening protocol is created for each straightening process. A robot cell is available as an option. Using this robot cell, the insertion and removal of the drills is performed. The robot cell is mobile and can be disconnected at any time in order to allow manual straightening processes.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

GSW SCHWABE AG

Germany

High quality, extremely simple operation, unreached price/performance ratio For decades, the GSW Straighteners are valued all over the world. The Straightener with clamshell head (the GSW “AlligatorHead”) came out in 1968 – the RMA series – and today is being built in up to 2000mm width. This machine levels coil set and equals out tension with up to 12mm thick materials. It has given GSW a pioneer’s position in the industry. The RMZ series Straighteners convince where high straightening and pull forces are needed. Its frametype head design provides a high stiffness and elevates this technology to work with high demands in straightening quality – even with highertensile materials.

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quote

ZINSER GMBH

Germany

High-precision plasma cutting machines from ZINSER - efficient cutting solutions for all applications ZINSER GmbH offers a wide range of high-precision plasma cutting machines that are known for their outstanding cutting quality and efficiency. Our systems are specially designed to cut mild steel, stainless steel and aluminum with the highest precision. Thanks to the latest technology and a robust design, our plasma cutting systems ensure maximum productivity and reliability in industrial production. ZINSER 4025B / 4125B / 4026B / 4126B These premium plasma cutting machines offer excellent cutting quality and reliability for demanding applications. They are ideal for cutting thick and thin materials and are suitable for both simple and complex cutting tasks. ZINSER 2315 / 2325 / 2425 / 2426 Our economical plasma cutting machines offer a cost-effective solution without compromising on quality.

Request for a quote

SCHNELL SPA

Italy

Automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Capacity 2 Ø 16 mm (#5) Max pulling speed 200 m/min (660 ft/min) Straighteners (horizontalsverticals) with electronic adjustment and independent position for the 2 wires Motorized wire change unit (Optional) Prestraightening Feeding Unit (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4), equipped with Senso Technology.

Request for a quote

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIFLEX-HYDRAULIK GMBH

Germany

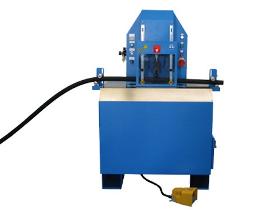

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 1 ¼”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The safe high-quality cutting machine for the production process. All cutting blades are made of carefully tested material which ensures optimum cutting quality. 7.5 kW drive max. For hydraulic hose assemblies up to 3” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Planetary cutting machine for corrugated metal and PTFE hoses. Cutting results that often eliminate an additional step. This completely unique planetary cutting machine delivers almost scrap-free production and high efficiency. With a completely variable centering clamp system, all hose OD to the maximum rating for the machine can be cut. Approximate cutting time is 25 seconds for 1 ¼“ (ø DN 32). Productive and ergonomic •No dramatic flaring of the stainless steel braid •Reduces or eliminates time-consuming manual preparatory work thereby increasing productivity and lowering costs •Centering hose clamp system •Shortest cut possible from 10 cm •Minimizes personnel costs and preparatory work •No wrapping/unwrapping with adhesive tape required •Clearly laid-out user friendly software on a panel with a 6“ color display screen •Large article memory promotes productivity •Reference run for optimal positioning of the cutting blade for cutting all hose diameters CE compliant

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

ZETAB MACHINERY

Turkey

ZETAMAK Rim Straightening Machines with 5 ton power capacity of Hydraulic Pump, Molded flange, Lathe and necessary accessories / equipment are used to straighten defected rims made up of alloy, chrome, mag and sheet iron wheels from 10" to 30". - CE certified - All parts have a 2-year warranty. - High quality electric box and cabling. - Reliable Hydraulic system. - Spare Parts support with no charge. - If requested OEM production is also possible.

Request for a quote

TFON MACHINE

Turkey

ProcessLeveling And Residual Stress Relieve Material Thickness (mm)0,3-5 Maximum Material Width (mm)200 Minimum Material Length(mm)70 Quick Change System for Straightening Rollers- Flattening Gap AdjustmentElectromechanics/PC Control Overload Protection- ScreenTouch CE-CertificateStandard Machine Size (mm)1585x1585x1820 Total Weight (kg)2000

Request for a quote

ZETAB MACHINERY LTD

Turkey

RIM Straightening Machine HYDRO 380/400V - 3ph - 50Hz. Hydraulic Motor : 0,75kw,1400rpm, 1 hp, This unique machine is used to correct and straighten all kinds of defected steel and alloy rims ranging from 10” to 22”. CE certified by KEMA Quality B.V. / The Netherlands

Request for a quote

ZETAB MACHINERY LTD

Turkey

RIM STRAIGHTENING MACHINE With LATHE SYSTEM & COMPLETED STANDARD ACCESSORIES. 380/400V - 3ph - 50Hz. Mechanic Motor : 0,55kw,1400rpm, 0,75hp Hydraulic Motor : 0,75 kw,1400rpm, 1 hp, This unique machine is used to correct and straighten all kinds of defected steel and alloy rims ranging from 10” to 22”. CE certified by KEMA Quality B.V. / The Netherlands

Request for a quote

TFON MACHINE

Turkey

ProcessLeveling And Residual Stress Relieve Material Thickness (mm)1-28 Maximum Material Width (mm)1500 Minimum Material Length(mm)145 Quick Change System for Straightening RollersStandard Flattening Gap AdjustmentServo Hydraulic/PC Control Overload ProtectionStandard ScreenTouch CE-CertificateStandard Machine Size (mm)5200x7185x2260 Total Weight (kg)40000

Request for a quote

ZETAB MACHINERY LTD

Turkey

DIMENSIONS ( PACKING) Height..................................... 1520 mm Length..................................... 1140 mm Width...................................... 800 mm Gross Weight........................... 380 Kg MOTOR SPECIFICATIONS Mechanic Motor.........................0,55 kw, 1400 rpm, 0,75 hp - 7,3 Ampere 3 phase - single phase // 380 V - 220 V Hydraulic Motor........................ 0,75 kw 1400 rpm, 1 hp - 8,7 Ampere 3 Phase - single phase // 380 V - 220 V Sound Level.................................35 db

Request for a quoteResults for

Straightening and cutting machines - Import exportNumber of results

35 ProductsCountries

Company type