- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel welding

Results for

Steel welding - Import export

METZEN INDUSTRIES GMBH

Germany

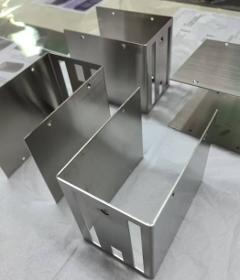

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the pipe made by stainless steel 304,mainly use for the connector.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for mechanical .

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our tasks also include joint process optimization with our customers in order to enable more efficient production and thus a reduction in set-up and downtimes. Our spooling systems are a good example of this type of cooperation and continuous further development. We connect the strips using state-of-the-art welding technology and rewind them oscillating on a variety of spools Strip widths from 1.5 mm up to 60 mm Extension of the strip length to more than 200,000 meters in one strip depending on the material Individual laying widths from 100 to 400 mm Special decoiling racks with decoiling widths of 800 mm and maximum decoiling weights of 2,500 kg

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP® Large Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The largevolume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. Speciality No additional nitrogen system necessary.

Request for a quote

ROTSTAHL GMBH

Germany

This locker is a classic for dressing rooms. Designed functional and timeless elegant it provides room for long clothes. Body: Made of sheet steel, tidy welded, with ventilation openings. Powder coated in RAL 7035 (light gray). Each compartment with shelf and clothes rail with hooks. Doors: Made of sheet steel, with welded reinforcement profile and powder coated in the color selected. Fixed with pintles. Each door with label frame and 2 bump rubber. Closure: Each door with master key capable cylinder lock with 2 keys. Other closures available as option. Variants: - number of compartments: 1; 2; 3; 4 - compartment width: 30 cm; 40 cm - great variaty of colours - different closures (PIN, RFID etc.) available

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BDSENSORS GMBH

Germany

Compact OEM Pressure Transmitter Heavy Duty Applications: ► mobile hydraulic, presses ► general mechanical engineering Characteristics: ► stainless steel sensor, welded ► accuracy according to IEC 60770: 0.5 % FSO ► nominal pressure ranges from 0 … 16 bar up to 0 … 600 bar

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The MZD 45/35 P portable clinching pliers are a hand-held device with a compressed air connection. The key features of this portable ECKOLD product are its lightweight design, large throat and 360° swivelling suspension mechanism. Thanks to the large throat and the excellent reproduction accuracy of the preset yet adjustable stroke, the pliers are particularly suitable for joining tasks in the HVAC sector. Other advantages of the device are the cheap tools, the sturdy overall design and the low maintenance costs. This offer includes: Portable clinching pliers MZD 45/35 P Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The stationary clinching unit DFG 400/50 PH is our cheapest model with which you can enter into a stationary and reliable production. A compressed air connection with a maximum inlet pressure of 16 bar is necessary and the operating pressure is adjustable. Designed for use cases in ventilation and ducting industry, sound proofing, steel and metal working industry, sign manufacturing, roof building, plumbing, computers, electronics and lighting industry. • Favourable stationary solution • Processing of bulky or hollow components • Large horizontal and vertical throat • High-value joining result due to adjustable path restriction • Reproducible results • Suitable for use under permanent load • Low-noise Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The MCD 30/5 PH portable clinching frame is a sturdy, light-weight machine with one-hand control. This clinching frame has been specially designed for mobile use. The portable clinching frame comes with a continuously adjustable stroke limitation for reproducible clinching result. Its frame head can be rotated by 360° for easy positioning on workpieces. The clinching frame is driven by our pneumohydraulic pressure booster PHD-002. • Handy, light-weight design • For mobile application • One-hand operating device • Adjustable path limitation • Frame head can be rotated by 360° This offer includes: Portable clinching pliers MCD 30/5 PH Pneumohydraulic pressure booster PHD-002 Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

This cordless clinching device is a low-cost and universal frame from the ECKOLD range of hand-held machines. Apart from the standard models, we offer of course also customised frames. Do you want to produce a prototype? Do you need a fall-back option for your production? Or are there clinching tasks to be performed on site? Then opt for the MCD 30/50 AH portable clinching frame. • Universal application • Portable and cordless • Sturdy design, suitable for construction side • Large opening width, good component accessibility • Frame head 360° turnable • Continuously adjustable path limit • Different clinching techniques possible • Comfortably packed in transportation case • LED light • Digital display • Klauke i-press software Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The MZD 60/6, MZD 60/6 D, MZD 60/6 W and MZD 60/6 D-W portable clinching pliers are hand-guided machines. These ECKOLD pliers come with a large throat and a high press force, which makes them the ideal tool for all clinching options. They can be customised with exchangeable tool holders for a wide range of applications. The clinching pliers have been specially designed for mobile use and come with a single-acting hydraulic cylinder producing a press force of max. 60 kN or 80 kN. The pliers are connected to the hydraulic unit with a 6 m hydraulic hose and a hydraulic drive unit. The various pliers are customised for specific applications. Contact us for specialist advice about our tool options for your joining tasks. Clinching tools (punch and die) are not included in the scope of delivery. They must be chosen separately, based on the actual joining task. Contact us for a customised offer, tools included!

Request for a quote

EWM AG

Germany

EWM welding consumables for MMA welding Welders can choose between different stick electrodes with different coating materials to work with: — unalloyed steels — low-alloy heat resistant steels — high alloy steels — Copper-based materials — Cladding

Request for a quote

EWM AG

Germany

Gas-cooled PM MIG/MAG-welding-torches, optional function torch with high-quality OLED graphic display. Available as PM 221 up to 250A, PM 301 up to 330A and PM 401 up to 450A — Secure hold thanks to rubber inserts in the grip — The flexible ball joint makes it comfortable to work with, even in difficult spots Highlights function torch: — Automatic LED lighting when welding torch is moved Display and adjustment directly from the workplace- — Welding current and wire feed speed — Voltage correction — Program and JOB selection — Welding process switching — Interferences and error messages — 2-/4-stroke — Choke — Welding processes (standard, pulse, coldArc, rootArc, forceArc) Also supports the Xnet welding management software: — Selection of the welding task according to the welding sequence plan — Component management

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

EWM AG

Germany

— MMA inverter welding machine with degaussing function and reversing switch — MMA /MMA pulse — TIG lift arc / pulse — GMAW (MIG/MAG) welding with Pico drive 4L or Pico drive 200C wire feeder — Arcforce, Hotstart, Antistick — CC / CV characteristics — Suitable for flux cored wire welding — Welding polarity can be reversed by pressing the button polarity reversing switch — Stick electrode/MMA cellulose electrodes: 100% safe for vertical-down welding

Request for a quote

EWM AG

Germany

EWM welding consumables for MIG/MAG welding Welders can choose between different welding rods with different diameters and materials to work with: — unalloyed steels — low-alloy steels — high alloy steels — Nickel-based materials — aluminium alloys — Copper-based materials — Hardfacing

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 350 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quoteResults for

Steel welding - Import exportNumber of results

66 ProductsCountries

- Germany (66)

- Bonn, Düsseldorf and North Rhine and Westphalia (25)

- Frankfurt am Main and Hesse (1)

- Hamburg and region (1)

- Hannover and Lower Saxony (6)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (15)

- Munich, Nuremberg and Bavaria (12)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (3)

- Weimar and Thuringia (1)

Company type

Category

- Welding work - steels and metal (23)

- Steels and metals - welding and brazing (19)

- Clutches (5)

- Welding, soldering and brazing - equipment and supplies (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Wheels, castors and rollers - rubber (2)

- Pipes and tubes, steel (1)

- Wires and cables, steel (1)

- Tanks, metal (1)

- Agricultural machines and accessories (1)

- Casting, steel (1)

- Factory furniture (1)

- Measurement - Equipment & Instruments (1)

- Polishing - machine tools (1)

- Sheet metal and strips, tinplate (1)

- Spraying equipment, agricultural (1)

- Storage tanks (1)

- Wheels, castors and rollers (1)