- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- single valves

Results for

Single valves - Import export

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ SUMONDO® single-use diaphragm valve consists of a diaphragm valve body and a manual or pneumatic operator. The single-use diaphragm valve body has an internally welded diaphragm. The single-use diaphragm valve body is fastened to the operator using a clamp. The valve body and the operator are locked using a defined closing and opening procedure. After use, the single-use diaphragm valve body and its diaphragm can be removed from the operator and disposed of. The operator can be used multiple times and remains in the plant. — Tried and tested actuator design — Impact resistant, corrosion resistant — The diaphragm valve body meets the purity requirements of the pharmaceutical industry (USP 85, USP 788) — Integral optical position indicator — Validation Guide on request — Gamma-sterilizable valve body

Request for a quote

CIC - KLAUS CZERWONKA

Germany

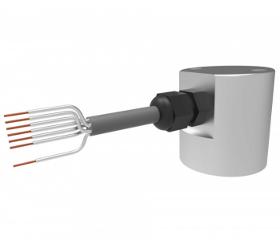

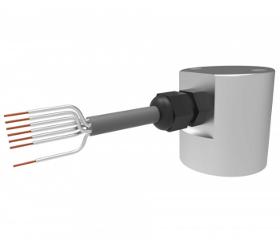

Our 15 mm valve series type VA. Valves controlled electrically and pneumatically, completely in aluminium. Available as a single valve or on modular manifolds for maximum flexibility. Core items: Reduced dimensions (15mm) Low power consumption (1 W) Modern design and compactness, for easy installation. Insensitive to pollution. Solid metal construction to ensure long runtime even in demanding environments Flexibility: The valve can be easily wall mounted, manifold mounted and multipolar connection units 3 different connection types LED display manual override Connection strips with exclusive modular system

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-F is a single-stage valve offering only the function of the second ventilation stage (fine ventilation) provided by the two-stage valve (BEV-GF). For ventilation quantities of 20 to 40 m3/h. Specific applications include high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required, as well as at high points with low flow quantities. Type F (fine ventilation): Air escapes through this valve, and collected gases cause it to open once again, including under operating pressure, until the medium continues to flow and close the valve again. Installed at high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required. Installed at high points of pressure lines with low flow quantities.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The diaphragm dosing pumps in the MEMDOS MR series have been developed for a wide range of applications in dosing technology. They are ideal for use in industry, process engineering, water treatment and waste water treatment. Features: . Robust dosing head: Made of PP and stainless steel for high durability and longevity. . Precise dosing: Double ball valves (up to MR 290) and spring-loaded flat-seat valves (from MR 290), optional spring-loaded single ball valves. . Safety: Separation chamber with drainage tube between dosing head and gearbox protects against leaks. . Flexible stroke adjustment: Can be adjusted manually or electrically (ATE). Optional extensions: . Dual dosing pumps for increased performance. . Stroke counting with inductive sensor for precise batch processes. . Frequency inverter control for variable control.

Request for a quote

GSW SCHWABE AG

Germany

electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve single/double band adaptor for surfacecritical materials telescopic guide for thin wire precision stock guide for thin materials special grippers for plate or profile materials mounting bracket with height adjustment via slotted holes heightadjustable base frames pullthru straighteners for strip and wire electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC complex electrical control units protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

GSW SCHWABE AG

Germany

electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve single/double band adaptor for surfacecritical materials telescopic guide for thin wire precision stock guide for thin materials special grippers for plate or profile materials mounting bracket with height adjustment via slotted holes heightadjustable base frames pullthru straighteners for strip and wire electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC complex electrical control units protective cover filterregulatorlubricator to clean and lubricate the supply air

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-G is a single-stage valve offering only the function of the first ventilation stage (coarse ventilation) provided by the two-stage valve (BEV-GF). It is not necessary to coordinate the valve to the working pressure in the first ventilation stage, since coarse ventilation is always closed under pressure. Type G (coarse ventilation): The air escapes through this valve until the medium closes it as it continues to flow. The valve remains closed under operating pressure. Ventilation of individual sections in sloped pressure lines, especially as a low pressure safety feature Quick ventilation of high points if fine ventilation is not required (short pump run times)

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

The standard firmware for all electronic systems provides precise control of speed and position. Other requirements can be programmed customer-specifically by KAG. Examples of implemented customer requirements: — Motor speed control for single-grain sowing unit — Valve control actuated via digital inputs — Automatic door control with temperature monitoring — Target position generator: Calculation of motor position according to customer-specific framework conditions — Speed control according to sensor input — Input of light barrier impulse signals — Reading a load balance via analogue inputs — Input of an external speed impulse

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

This perfectly constructed machine can be also fitted at the front with a pair of high-performance supports instead of a single one and is, therefore, the ideal tool for extreme and long-term use. It is nevertheless light and sits snugly in your hand. Due to the high speed of this grinder it creates a very clean pattern, which makes it ideal for fine grinding, milling and engraving jobs. The following variants of the machine are available: Support: Single or pair Valve: Rotary or lever valve Exhaust air direction: Backwards or forwards

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Gauge Isolator Valves SWS-S1 (Single Station) ▪ Effective protection of pressure gauges against overload caused by pressure peaks ▪ Suitable for panel installation ▪ Push button to read and turn to lock ▪ Multilingual instructions printed on face plate ▪ Maximum working pressure: 400 bar / 5800 PSI Gauge Isolator Valves SWS-A1/A2 (Single Station) ▪ Effective protection of pressure gauges against overload caused by pressure peaks ▪ Designed for in-line assembly (type A1) or 90° assembly (type A2) with female BSP / male BSPT, female NPT / male NPT or female NPT / male SAE threaded connections ▪ Panel mounting nuts available on request ▪ Rotating swivel nut allows for accurate orientation of the pressure gauge ▪ Maximum working pressure: 400 bar / 5800 PSI

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VD2 refaces the valve seat in a lathe-type facing action. The tool head includes two inclined slideways for refacing 30° and 45° valve seats. A single point turning tool is clamped to tool slide guided in the respective slideway. When the VD2 is rotated around the pilot by hand, the turning tool travels in a circle around the valve seat with continuous outward transverse feed motion under the correct seat angle. A steady rest which is mounted on the cylinder head stabilizes the VD2 below the crank handle. The steady rest eliminates runout when rotating the VD2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MÜLLER CO-AX GMBH

Germany

Whenever several valves are to be used in a confined space and with minimal piping, a module or strip solution is recommended. In contrast to single piping, the expense for valve piping, fittings, working time, and possible leaks is almost cut in half.

Request for a quote

HARTMANN VALVES GMBH

Germany

The Hartmann Twin Ball Valve (TBV) provides a double line barrier and enables a significant increase of safety without much effort. Designed for applications with especially high safety requirements, the TBV consists of two integrated ball valves, which can be equipped with two independent barriers each. Thereby the safety can be raised by factor 4 compared to a standard valve. With the Double Isolation and Bleed function each ball valve seals both at the upstream and downstream side. With the so-called „studded“-design, meaning a closed flange form, the valve has the length of a single standard valve and affords a compact and economic alternative for the application of multiple valves. The TBV comprises – like all Hartmann valves – a pure metal-to-metal sealing system between ball and seat ring. With this sealing system leakage rates A, respectively 0, can be fulfilled. Furthermore, it is characterized by an outstanding longevity and low maintenance requirements.

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The CETATEST 715 series includes fully automatic working leak tester for the detection of untight parts within the cycle time of the production process. The leak tester uses a gauge pressure sensor and has a large measurement range. Therefore the CETATEST 715 is especially qualified for the simple testing of parts with large leakages, as they occur in the testing of valves. The test types "sealed component" and "dynamic pressure" can also be integrated. Typical applications: Testing of sanitary fittings, plastic welds, check valves Operating methods: Single-channel operation, two-channel operation The measurements in two-channel operation are synchronous. Measurement ranges: Max. +/-10,000 Pa Result units: Pa, hPa, PSI, Pa/s, hPa/s, mbar*l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr Pressure ranges: -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar, 16 bar, 20 bar, negative gauge pressure and positive gauge pressure ranges can be combined.

Request for a quoteResults for

Single valves - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Electric motors - dC (7)

- Machine tools, metal shaping - parts and accessories (2)

- Water - production and distribution (2)

- Adjustment - machine tools (1)

- Cylinders, pneumatic (1)

- Paint mixers and grinding machines (1)

- Precision measuring instruments (1)

- Pumps (1)

- Taps - adjustable controls (1)

- Valves for industrial fittings (1)