- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- saving potential

Results for

Saving potential - Import export

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

We prepare hand-made samples to establish the design, 3D constructions, prototypes and pilot series – our collaboration commences with your specific idea or problem. We pride ourselves on our service orientation and advise you comprehensively on solution approaches as well as production options.

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

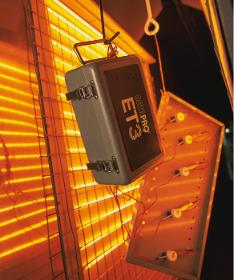

EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. It is the third generation of the globally accepted Datapaq EasyTrack brand successfully used in the powder and paint coating market by applicators and coating suppliers. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: Monitor and prove QA Optimize your powder coating oven performance and save energy costs Identify potential problems in your powder coating process and correct them quickly and efficiently Customize your EasyTrack3 system with ET3 temperature datalogger and a choice of thermal barriers, software and thermocouple range to meet your exact industrial coating process needs. For detailed information download the EasyTrack3 Brochure, EasyTrack3 Datasheet and EasyTrack3 3 Key Wins. EasyTrack Insight™ Software

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The special model ASW 560 for industrial applications offers the latest technology and premium quality: Combine cutting or flattening in conjunction with the Weber automatic initial cut function in one machine. That means that virtually no manual post-processing is required after the processing workflow, even for cheek and very cold material. Can optionally be used with a blade shaft for cutting into the product to be derinded. That leads to an optimal derinding result with a residual rind of less than one percent (temperature dependent) for pork cheek or use with upstream pressure device (roller) instead of the blade roller. Advantages Two work procedures in one machine increase product throughput Almost no more manual post-processing required, even for pork cheeks and highly cooled materials – potential labour savings Options: Operation from left or right Product-specific pressure devices for the derinding process Special sub-frames (height adjustment)

Request for a quote

RHEIN-CHEMOTECHNIK GMBH

Germany

Nano-CSH based nitrate-free accelerator of hardening of the latest generation for higher strength at an early stage of hydration. Concrete and reinforced concrete in accordance with DIN EN 206-1 in conjunction with DIN 1045-2, also in prestressed concrete. Considerably quicker formwork handling in precast concrete production, significant reduction or total absence of heating measures, reduced CO2 emissions, potential savings on cement, use of cement with lower clinker content or increased proportion of cement substitutes, concreting at lower temperatures, earlier attainment of minimum strength required for frost resistance, improved durability (for example, reduced water absorption and improved impermeability of the concrete).

Request for a quote

FLOTTWEG SE

Germany

Sewage sludge dewatering offers enormous potential savings for operators of sewage treatment plants. Dewatering sludge means reducing the quantity of sludge for disposal. Depending on system capacity, 1 percent more dry substance can lead to cost savings in the five- to six-digit range. The dewatering performance of the Flottweg Xelletor Series is significantly better than even its predecessors. It sets new benchmarks for throughflow, dry substance, and polymer and energy consumption. The Xtra in performance at low consumption in comparison with our high-performance C Series: ►Xtra dewatering performance: Up to 10 percent less sludge volume due to higher total dry solids in dewatered sludge ►Xtra polymer savings: Up to 20 percent savings on flocculant consumption ►Xtra capacity: Up to 15 percent more throughflow ►Xtra energy savings: Up to an additional 20 percent energy savings

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N at 6-7 bar air pressure Productivity and savings potential • Up to 40 blind rivets can be processed every minute • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Electronic system controls • Intuitive menu guidance via navigation and function keys • Function display • Maintenance display and simple fault diagnosis • Customer-specifi c software modifi cation is possible • Ideal for applications that do not require any process monitoring • Rivet mandrels are disposed of by vacuum system • Spring loaded trigger system as an optional extra available • Can be integrated into the system or operated independently • Interface for external memory programmable control system (SPS) can be realised via the GESIPA® interface

Request for a quote

CRAEMER GMBH

Germany

The 120 - 360 l MGBneo are an economic solution for modern waste management companies. They comply with DIN EN 840 and RAL-GZ951/1 (GGAWB) and are noise reduced according to EU directive 2000/14/EG. Characteristics: — Optimised construction for an economic use of storage space — Stacks of up to 13 (selected bin sizes) enable cost saving potential for transport and storage processes — Robust thanks to uniform wall thickness and reinforcement of all walls — Large printing area offers space for individual labelling — Release pins allow quick and easy lid replacements — DDA notch option for ease of bin identification — Coloured lid inserts for optional colour-coded identification — External wheels, available with 200 or 250 mm Ø rubber tires

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ temperature profiling systems include high-accuracy industrial-strength data loggers, analysis software, thermal barriers, and thermocouples. EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: • Monitor and prove QA • Optimize your powder coating oven performance and save energy costs • Identify potential problems in your powder coating process and correct them quickly and efficiently The range of thermal barriers is designed to match different coating applications or operational needs. These provide dual protection confidence using microporous insulation and phase change technology and maintain logger temperatures at a level to guarantee the accuracy of the temperature measurements recorded.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The benefits of using aluminium in machine and plant construction are abundant: although aluminium is considered to be a light metal with a density of 2.6 to 2.8 g per cm³, which offers potential weight savings of up to 66% compared to steel and stainless steel, it still has exceptional strength considering these properties. However, the design and concept of steel constructions can often not be transferred one-to-one, due to the higher malleability and lower residual stress of aluminium components. An additional benefit is the aluminium's inherent resistance to corrosion: When exposed to oxygen, the light metal forms an oxide coating, which is immediately regenerated upon permeation. Standard processing methods, such as MIG, TIG and CMT welding can easily be used on aluminium without hesitation – particularly on substrates that are also made of aluminium. In some instances, they can be carried out more easily, more quickly and using simpler equipment, which results in further...

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Heating technology with a future The calculation is simple, the technology successful. Efficient surface drying is achieved with biomass in Rippert plants. Together with the Hargassner company from Austria, a specialist for heating with biomass, and the proven Rippert plant know-how, the technology is now marketable and has gone into production. The demanding drying characteristics in a powder-coating plant are compatible with the process and work perfectly. A future-orientated heating technology with considerable economic and ecological benefits – the experts are unanimous in that. Wood pellets or wood chips are the inexpensive energy suppliers. They are valuable waste products that result from the processing of domestic timbers. Heating with wood chips – without intermediate heat transfer media such as thermal oil • Environmentally friendly and CO2-neutral • fully automatic boiler cleaning and ash discharge Maximum financial saving potentials are realised with this energy carrier. Wood chips, chopped to a transportable size and dried by the supplier, are stored in the storeroom near the plant. It can be located on the same level or lower. A tried-and tested transport system consisting of a floor agitator with springs and discharge auger carries the wood chips reliably into the plant. Here it acts as a fuel with maximum convenience. If the calorific value equivalents are examined, we see that 1,000 litres of fuel oil is equivalent to 12 m³ of wood chips. The ratio is the same for 1,000 m³ of natural gas. Heating with wood pellets - without intermediate heat transfer media such as thermal oil Wood pellets are true energy bundles. They consist of natural wood and are made by compressing sawdust, which is produced in large quantities every day in the industry. As a biomass they are the alternative to wood chips and are just as advantageous from an economical point of view. Pellets have the smallest volume and are conveyed dust-free and without odours from storage containers to a storage vessel next to the plant. They are transported into the combustion chamber via a rotary vane feeder and feed auger. For comparison: 1,000 l fuel oil = 2 t pellets 1,000 m³ natural gas = 2 t pellets 1,000 l liquefied gas = 1.32 t pellets Advantages • Reduction in energy costs Heating cost comparison (reference = 1,000 l fuel oil)

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Better fuel quality for combustion Blend fuel improvement Prevent sludge in case of fuel incompatibility Increases amount of burnable fuel Less wear and tear on engine components Optimization of combustion process Fuel treatment / conditioning Less clogged filters Areas of application The Homogenizer is a dynamic milling machine which can be used in the fuel system on board ships. It is designed to improve your fuel quality which will lead to a better combustion and less maintenance. Furthermore it can reduce sludge in case of fuel incompatibility. Increase the amount of burnable fuel in case of bad fuel quality. The Homogenizer has a high saving potential.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our Breeze technology has many enormous advantages over the previous classic lubrication applications. Discover enormous savings potential for mass production when using our LSJ Mini in your process. This system can be used optimally in the event of always consistent tool operations. For the machining process, an average of between 5 and 50 ml of lubricant is used per process hour and tool. These consumption values can also be briefly — depending on the requirements of the individual operation — increased to up to 200 ml per process hour. In addition to this excellent advantage over the previous method, the HPM Breeze method offers further enormous advantages from an economic and ecological point of view. • For optimum use with a cooling channel diameter of 0,9 mm² and up. • Manual adjustment of the pressure parameters • Optimally suited for consistent series processes with one parameter

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The EcoResinator is particularly suited to full the specic demands that are made on the technology employed for the glue-blending system used to manufacture MDF. Siempelkamp has equipped the EcoResinator with Schlick two-component nozzles. The second component that is used with the glue is steam. The size of the glue droplets is set with the help of the steam pressure and quantity. The corresponding parameters required for achieving the best possible application of glue based on the breboard's density are stored in the program. The optimised gluing methods may either be used to improve strength with the same amounts of wood and glue o and bres while preserving the same strength. The EcoResinator can potentially save up to 15% of glue over classic b recommended for all MDF plants. The EcoResinator also oers benets when existing plants are modied at a later point in time. The glue-blending sy within 24 hours.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thickness measuring systems THICK-SCAN behind the ContiRoll® optimizes the process and to reduces the costs while, at the same time, assuring the quality standard. If the gauges are located in the sanding line, the tool life of the sanding belts is enhanced and the quality is assured. The time is long past since panel thickness tolerances have been measured during production by handheld devices. Today, however, such measurement is carried out continuously online. In the majority of plants, quality control is not the rst priority for new investment for online thickness measurement. The current trend is to achieve the enormous potential savings in wood raw material, resin and energy consumption. If the upper tolerance level is exceeded, valuable resources are wasted. The Thickness Gauge prevents such losses. It is robust and reliable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OS5 bag packer and packaging machine offers a new method for packaging tissue paper into either polyethylene bags or polyethylene film with the integration of reasonable product compression during the packaging process. The final packed product comes out as a nice, tight, compact package which is easy to palletize. Carton boxes for the secondary packaging are not needed anymore. The press capacity allows perfectly adapted product compression without any quality deficits. Due to the tight and compact film package, the number of truck loads required for transporting only the packaging material is significantly reduced as well as for the transport of the final package. Altogether, the new packaging method gives a high potential in cost saving on packaging material warehouse storage, shelf space and logisitcs and it is environtmentally friendly. Quick and easy change-over Premade polyethylene bags on wickets Carry-handle possible

Results for

Saving potential - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Water treatment, industrial - systems and equipment (2)

- Wood veneer - machinery and equipment (2)

- Automation - systems and equipment (1)

- Concrete products and conglomerates (1)

- Drainage systems and equipment (1)

- Dustbins, waste bins (1)

- Filters, liquid (1)

- Heat exchangers (1)

- Infrared tubes (1)

- Meat processing machines (1)

- Metals - Machines & Equipment (1)

- Paper and cardboard manufacturing - machinery and equipment (1)

- Temperature sensing devices (1)