- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rubber elastomers

Results for

Rubber elastomers - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

In the cryogenic blasting process, an enrichment of rubber and plastic waste powder takes place due to fine abrasion during the treatment procedure. Thus the performance and processing time of the blasting-media will deteriorate and decrease its jet-energy. In our cryognic deflashing machines, the blasting-media is primary screened by the treatment drum perforation, however, after a long operating time the amount of rubber and plastic waste powder increases. In order to guarantee a constant, statistically secure and economic processing, this powder has to be removed periodically from the blasting-media. Our automatically working blasting-media recovery machine consists of a suction & drying system and a vibrating-screen unit. The used blasting-media has to be aspirated manually from the deflashing machine. The drying of the polluted wet and cold media takes place in the suction tank and the cleaning by screening with final separation into waste powder, waste media & re-usable media,

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W90 offers maximum economic efficiency on treatment of big batch volumes at high throughput!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer. Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose. The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Request for a quote

VOLFI VOLKER FISCHER GMBH

Germany

Cost effective slab support with dimpled base for an ideal drainage of surface water. More than 60 versions available for different joint sizes and bond types. Choose VOLFI Basic Supports made from rubber-coated high performance elastomer for additional benefits.

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

We produce expansion joints for all industrial sectors to take up vibrations, for noise absorption, or to compensate distortion by axial, lateral or angular movements. Our expansion joints are available in various versions and numerous elastomers variants in inner diameters from 25 mm to 1600 mm. Testing certificates of all well-known testing institutes are at hand. TYPE II Single or multiple flutes with rubber/fabric flange. Various elastomers qualities. ND 32 to ND 1600, Standard length n 250, 300 und 350 mm, Standard pressure stage 10 bar. TYPE V and TYPE VII Single wave with rubber sealing bead. Various elastomers qualities. ND 32 to ND 600. Standard pressure stage 10 bar. TYPE V Standard length 100 mm TYPE VII Standard length 130 mm HKS and HKA Per heating standard DIN 4809. COUPLING EXPANSION JOINT Single or multiple flutes, in various elastomers qualities. ND 25 – ND 750, any length for pressures from –0,8 to +15 bar, with clamping band. RUBBER-METAL PIPE...

Request for a quote

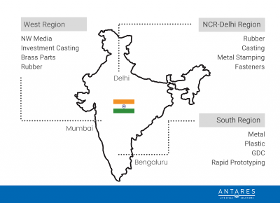

ANTARES LIFE CYCLE SOLUTIONS GMBH

Germany

Components in small volumes, replacement parts which are difficult to source or have even become obsolete, requirements and customer demands that fluctuate substantially (and are therefore effectively unplannable) All these are challenges in the day-to-day life of OEMs and TIER-X manufacturers in off-highway, commercial vehicles, mechanical engineering and many other industries when it comes to delivery performance towards end-customers. Our solution: for every case the most suitable manufacturing technology combined with our own experienced engineering team – everything from a single source. Technologies: Additive Manufacturing / 3D printing Casting Parts (sand casting, pressure casting and many more) CNC Parts Technical Plastics Parts Rubber and Elastomer Parts (gaskets) Assembly of Modules and Systems and many more

Request for a quote

GOODRIDGE GMBH

Germany

Material / Construction: Textile reinforced rubber with elastomer cover Temperature range:- 40 degrees to 100 degrees

Request for a quote

JAPAN STEEL WORKS EUROPE GMBH

Germany

For compounding and reactive process, JSW propose “TEX-αⅢ” series. TEX-αⅢ has the world’s highest level torque (Td = 18.2 Nm/cm3) with deeper Do/Di ratio (1.57). The highest torque of TEX-αⅢ makes it possible to operate the extruder with lower screw speed comparing with the existing extruder. As a result, TEX-αⅢ can realize the lower energy consumption and lower discharge temperature. TEX-αⅢ has 9 line-up from TEX25αⅢ(screw dia. 26.5 mm) to TEX120αⅢ (129.5 mm). For the isolation process after polymerization, we provide devolatilization extruder which has multi vacuum vent ports in order to remove residual solvent and/or monomer in the material polymers. JSW also provides the mechanical dewatering twin screw extruder for plastics, rubber and elastomer.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Elastomers are macro-molecular, organic substances with little cross-linked structure. As a result, they do not melt, are insoluble, partly subject to swelling and are elastic. Elastomers are based on rubber which is processed into various kinds of synthetic rubber, depending on the monomer. The various kinds of synchetic rubberdiffer slightlys in their properties so that they are used for different applications with regard to temperature, hardness, elasticity etc. In addition to generally common mouldings such as Orings, our delivery range also includes customized mouldedarticles, profi le cords, punched or cut seals manufactured to specifi cations or to drawings, plates or rollers. Elastomer materials: - NBR - EPDM - CR - CSM - FPM - VQM - NR - EPDM

Request for a quoteResults for

Rubber elastomers - Import exportNumber of results

16 ProductsCountries

Company type