- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- proportioning valves

Results for

Proportioning valves - Import export

KENDRION KUHNKE AUTOMATION GMBH

Germany

2/2 way Proportional Valve Type 68P with 15 mm width and two different electrical connection possibilities. The steady valve opening allows a continuous adjustment of the flow. This proportional behaviour between control input and flow follows the valves unique characteristic curve and can be regulated with appropriate sensors and electronics for high precision.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

2/2 way proportional valves, 10 mm width, three different electrical connection possibilities. The steady valve opening allows a continuous adjustment of the flow. This proportional behaviour between control input and flow follows the valves unique characteristic curve and can be regulated with appropriate sensors and electronics for high precision.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

2/2 way proportional valves, 10 mm width, three different electrical connection possibilities. The steady valve opening allows a continuous adjustment of the flow. This proportional behaviour between control input and flow follows the valves unique characteristic curve and can be regulated with appropriate sensors and electronics for high precision.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

2/2 way proportional valves, 15 mm width, two different electrical connection possibilities. The steady valve opening allows a continuous adjustment of the flow. This proportional behaviour between control input and flow follows the valves unique characteristic curve and can be regulated with appropriate sensors and electronics for high precision.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

2/2 way proportional valves, 15 mm width, two different electrical connection possibilities. The steady valve opening allows a continuous adjustment of the flow. This proportional behaviour between control input and flow follows the valves unique characteristic curve and can be regulated with appropriate sensors and electronics for high precision

Request for a quote

STAIGER

Germany

Proportional regulation and control of high flow rates • Frictionless movement; • High flow rates; • Small footprint and size; • Low power consumption; • Pressure-balanced; • High dynamics; This valve combines the advantages of the Spider-μProp technology with the benefits of a pressurebalanced valve. Due to its large orifice, high flow rates are possible. Furthermore, the valve is distinguished by a high reproducibility of the lift-off point. The electrical power consumption lies thereby in the lowest range of the Plate Armature Technology. The compact design of the valve provides a variety of assembly options for different areas of application.

Request for a quote

STAIGER

Germany

• Seat principle, direct actuated; • Frictionless movement Spider µProp-valves are real proportional valves, in which the armature stroke is proportionally defined by the infinitely-variable current applied. The constant ratio between armature stroke and flow rate thus allows variation of the flow rate by way of the applied current. Spider µProp-valves are like Spider on/off valves microvalves The anchors installed in the micro valves have the shape of a disk. In energized status, this so-called flat armature is pulled against the magnetic yoke component group. If the coil is deactivated, the leaf spring joined to the flat armature presses the seal positioned on the spring-armature assembly unit against the valve seat. These quick-acting valves owing to the small mass of the installed armature achieve switching phases in the millisecond range. These valves have a capacity of up to 4 billion actuations, depending upon operation mode.

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, stationary continuous mixing plants (pugmills) are mainly used for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Equipped with 5000/2500 l. capacity ELKON continuous twinshaft mixer, there two models of pugmill plants, 300 tons/h and 500 tons/h capacity. In this mixing plants, thanks to aggregate bins equipped with dosing belts, it’s possible to adjust material flow rate by means of frequency inverters. Cement flow rate can also be precisely adjusted by a screw equipped with frequency inverter whilst the water flow by a proportional valve. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Load bearing capacity up to 150 t Hydraulics with switching or proportional valve technology Movable or stationary With coupling facility With installed materials handling technolog With or without synchronous run control

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

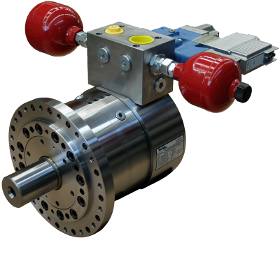

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

In addition to pressure, temperature, rotational speed and flow measurements, the Hydraulic Testers can measure and evaluate different signals from other or third-party sensors. Measuring electrical signals from third-party sensor (e.g. 4 ... 20 mA, 0 ... 10 V, ...) with the PPC-06/12-A/V-A Adaptor. The PPC-06/12-A/V-A Current/ Voltage Adaptor is used, for example, for measuring current at proportional valves or for determining the switching states of motors or pumps and to evaluate and process measurements from third-party sensors. Typical applications are the generation and measurement of a force-distance graph or torque-flow characteristics curves. The following input signals can be processed by this adaptor: ▪ Electrical currents up to 4 A DC ▪ Electrical voltages up to 48 V DC The measured data are transmitted directly to the Hydraulic Testers by a permanent cable connection.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Simplicity without having to abandon the proved Herrmann Ultraschall standards – that are the characteristics of this machine type. Proportional valve technology and digital high-performance generators are basic equipment. A solid machine design with precision guiding rails and proved drive components are the foundation for quality and repeatable welds.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Robustness, accuracy, and simplicity are attributes characterizing this ultrasonic welding machine. The entry-level models already include a position measuring system and proportional valve technology as basic equipment. Moreover, password protection and part counter are standard. Precision guiding rails and reliable drive components ensure repeatable welds.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The name delivers what it promises. The ultrasonic welding machine HiQ VARIO can be configured to completely suit the customer’s needs. A large number of pneumatic drive modules with different strokes and cylinder diameters are available, always including the reliable proportional valve technology by Herrmann Ultraschall.

Request for a quote

KLN ULTRASCHALL AG

Germany

The new generation of plastic welding machines of the OMEGA 4 series combines technical standards at the highest level with ease of use. The modular arrangement of the machine components, consisting of press, control and generator, enables easy adaptation to the respective plastic part and the respective location. Simple system operation is guaranteed with the multilingual touchscreen With this standard machine, even the most difficult welding tasks can be mastered reliably thanks to their performance and control and monitoring options. The X series is the premium version of the Omega series. This series is also equipped with a proportional valve for a defined pressure control. In addition, this Omega series has a pneumatic pressure / counter pressure system and thus ensures smooth movement even at low pressure.

Request for a quote

KLN ULTRASCHALL AG

Germany

The REK-B offers all advantages of the high technical level of the OMEGA III series, particularly regarding precision and reliability. The machine may be integrated in an automatic production line and controlled via a higher-ranking control system (PLC). Options: • Hydraulic oil brake • Working table • Housing • Light curtain • Rotary table • Control of external periphery Advantages: • Easy programming via touch panel TP 270 • Display of time-travel curve and pressure-time curve after the welding cycle on a graphic display with plain text. • Regulation of the welding forces via proportional valve technology. • The machine REK-B offers many possibilities for analysis, control and regulation. • Three welding models in order to meet the requirements of each application • Positioning of the spin head prior to and after the welding process • Display of the ongoing process parameters ( welding travel, -time).

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC SMC is equipped with an integrated proportional valve. This allows the analyser to automatically regulate the gassing in a wide range of processes. All settings for the control can be configured on the unit or via external signals. This means that the customer is not required to control the process completely manually. This gives you the option of controlling the gassing at our analyser or at the plant. For some processes, a single adjustment is sufficient and the production runs fully automatically from then on. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quoteResults for

Proportioning valves - Import exportNumber of results

25 ProductsCountries

Company type