- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- printed circuits

Results for

Printed circuits - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Electroplating, also known as electrochemical deposition or electrodeposition, is a process that involves coating a solid substrate with a thin layer of metal through the reduction of metal cations using direct electric current.Electroplating is widely used in industry and decorative arts to enhance surface qualities such as abrasion resistance, corrosion resistance, reflectivity, and appearance. It's used to build up thickness on undersized or worn-out parts (electroforming) In electronics, it deposits copper for printed circuit boards and interconnects in integrated circuits. Electroplating can also purify metals like copper.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Use: Miniature Jack/Socket for thermocouple and RTD circuits. Designed for direct soldering onto printed circuit boards. This version is suitable for flat mounting other versions available, please see separate specification sheet. Mechanical design: • Housing of fibreglass-filled plastic. • Contacts of original thermocouple materials and • spring-loaded sockets for reliable contact. • Moulded barriers prevent short-circuits. • Reverse polarity protection by different contact pin widths. • One-piece housing withstands great stresses.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Use: Miniature Jack/Socket for thermocouple and RTD circuits. Designed for direct soldering onto printed circuit boards. This version is suitable for flat mounting other versions available, please see separate specification sheet. Mechanical design: • Housing of fibreglass-filled plastic. • Contacts of original thermocouple material and spring-loaded sockets for reliable contact. • Moulded barriers prevent short-circuits. • Reverse polarity protection by different contact pin widths. • One-piece housing withstands great stresses.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Use: Miniature Jack/Socket for thermocouple and RTD circuits. Designed for direct soldering onto printed circuit boards. This version is suitable for flat mounting other versions available, please see separate specification sheet. Mechanical design: • Housing of fibreglass-filled plastic. • Contacts of original thermocouple materials and spring-loaded sockets for reliable contact. • Reverse polarity protection by different contact pin widths. • One-piece housing withstands great stresses.

Request for a quote

CRYOSNOW GMBH

Germany

• Optimum handling by compact design • Very low consumption • For difficult to access operations • Small and powerful • No power supply necessary, as driven pneumatically • Maintenance-free • For cleaning injection molds, devices, small components, printed circuit boards, ...

Request for a quote

DYMAX EUROPE GMBH

Germany

Dymax Dual-Cure 9014 encapsulant is formulated to cure primarily with UV light and includes a secondary moisture curing function for applications where shadow areas exist on printed circuit boards. Features: - Cures with UV/Visible light - Dual Cure secondary moisture cure capability - Fluoresces blue under black lights - Flexible

Request for a quote

TEPROSA GMBH

Germany

Mechatronic integrated devices or molded interconnect devices (injection-molded circuit carriers) are spatial electronic assemblies – so-called 3D-MID. A special process is used to apply metallic conductor tracks to a specific substrate material (often plastic), thus creating three-dimensional assemblies that also serve as circuit carriers. These spatial electronic assemblies are manufactured using 3D-MID technology and, compared to conventional assemblies, enable the integration of electronic, mechanical, fluidic, optical and thermal functions. The resulting additional benefits represent advantages that cannot be realized with two-dimensional circuit carriers (printed circuit boards).

Request for a quote

TEPROSA GMBH

Germany

In an environmental simulation, assemblies are subjected to defined environmental conditions to validate their behavior under those conditions. The variables of an environmental simulation test include climatic aspects such as temperature (cold, heat), the air conditions (humidity, wetness), mechanical influences such as dust, vibration, vibration or impacts, and corrosive environmental effects such as salty lift (salt fog). As an environmental simulation laboratory, we simulate these environmental conditions in our climatic chambers and climatic chambers, creating real conditions to investigate the long-term behavior of the test specimens in reality. Environmental simulation and thermal shock testing laboratory for electronic assemblies and printed circuit boards We specialize in performing environmental simulation and temperature shock testing of electronic and mechanical assemblies. With over ten years of experience with the requirements of the automotive industry and medical

Request for a quote

TEPROSA GMBH

Germany

We are specialist in strain gage strain measurements on printed circuit boards and all other components. We carry out the application of strain gages and determine for you the actual stresses that occur, or the strain (also strain-rate) on a specific or several components in the manufacturing or assembly process. We perform our DMS measurements with certified measurement technology and according to the specifications of IPC/JEDEC-9704A. Expert advice from TEPROSA When measuring strain, in addition to many factors such as the appropriate measurement technology, it is also important to rperform the strain measurement correctly and to ensure that the sensors record the forces correctly. To ensure that the deformation of an object is correctly determined, it is therefore crucial to select the right strain gauges (also known as measuring strips) and to place them in the correct position on the measured object.

Request for a quote

SAMSYS GMBH

Germany

The Gecko Gripper (SP) enables the use of the innovative Gecko adhesive gripper technology in applications with a small surface area. Such areas which could not be automated so far. The gecko-inspired adhesive technology offers precise, track-free gripping. Even with porous workpieces this technology works. For example printed circuit boards or glossy surfaces. Cleaning is not necessary. The three different Gecko Single Pad Grippers (SP1, SP3 and SP5) are named after their payload in kilograms. Of course, the Gecko grippers can be used with leading lightweight robots and cobots. The compact single-pad design allows easy access to the workpiece, even in tight spaces. Since no electronics or air supply is required, the Gecko SP is a cost-effective plug-and-play solution. The Gecko gripper leaves no marks on glass. This eliminates the need for manual cleaning. This means a higher RoI and lower operating costs.

Request for a quote

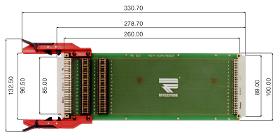

ROTH ELEKTRONIK GMBH

Germany

Extender card for 19"-systems DIN 41612 C64 a+c Epoxy fibre-glass FR4 1.50 mm Single-sided 70 µm Cu Solder stop mask Component print Removable short-circuit bridges and two measuring posts for each continuous strip Signalling line pin 2 - 31 Large signalling line pin 1 + 32 Switching voltage 10 mV - 60 V Switching current 0.5 A at 24 V Rest current at 20° C max. 2 A Contact resistance 20 mOhm Extender card: 100% electronically tested Size 100.00 x 278.70 mm (132.50 x 330.70 mm with handle)

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

The smallest electronic components, such as chips or connectors, present special challenges for electroplating coatings. In addition to the conductor pattern construction in the manufacturing of printed circuit boards, copper processes are used for filling blind microvias (blind holes) and metallizing through holes. Good metal distribution is necessary even with unfavorable geometry. The most important application areas are found in the automotive industry, telecommunications, and consumer goods industry, but also in the field of e-mobility.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Schlötter Systems Dr.-Ing. Max Schlötter GmbH & Co. KG is among the leading manufacturers of electroplating systems and surface treatment facilities. With more than 1,000 systems realized since 1957, we draw upon a wealth of experience in production-ready solutions. At Schlötter, we leverage our expertise in systems engineering and surface technology to precisely tailor each system to the coating processes required by our clients. We design and manufacture rack, barrel, and manual systems, modernize facilities, and support our customers with our systems technology services throughout the long lifespan of our systems. Rack systems Barrel systems Manual systems Electroplating systems Anodizing systems Cleaning and pickling systems Chemical systems Printed circuit board systems Plastic electroplating systems Schlötter Systems in All Surface Technology Industries Schlötter systems are utilized for a wide range of surface technology applications.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • Cutting edges inductively hardened • Precision cutting edge for the finest wires • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Tabletop robots from IAI are precise positioning and assembly platforms with working areas between 200 x 200 mm and 500 x 500 mm. Customers appreciate the rapid operational readiness without mechanical effort, for example for: ▸ Soldering and simple pick & place tasks ▸ Sorting applications ▸ Microdosing in biotechnology ▸ Assembly of printed circuit boards in the electronics industry ▸ Screw-in and press-fit in mechanical engineering ▸ Surface coating ▸ Quality assurance With a stroke of up to 150 mm, the Z-axis can also accommodate camera systems for image processing and move a total load of up to 15 kg.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Optometer module. Feature: The X1 optometer is available as a printed circuit board either with or without a housing and is suited for applications that do not require a keyboard or display. Four signal inputs enable connection with all measuring heads from Gigahertz-Optik.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JUKI AUTOMATION SYSTEMS GMBH

Germany

Handling Systems for Handling Printed Circuit Boards JUKI’s handling solution includes a wide range of reliable products to assure the secure handling of printed circuit boards involving SMT manufacturing conveyors; loaders and unloaders; buffers for PCBs; other systems such as turn units, stacker units; customised solutions for individual customer requirements etc. JUKI believes in durability and reliability. Our handling products are suitable for the requirements both of small and large production systems – while providing a highly attractive price performance ratio. Our partner Electro Design has more than 30 years of expertise in the development and manufacturing of handling systems for the electronic industry. In 1987, the company marketed its first conveyor belt and has since sold about 5,000 units to customers worldwide.

Request for a quote

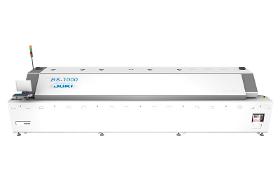

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Speed Mounter JUKI’s FX 3 stands for ultra fast, precise placement of micro components on printed circuit boards. It is the perfect solution for companies wanting to process large volumes. Among the strong points of the FX 3 are short retooling times thanks to quick change feeder banks as well as minimal maintenance. The user friendly touchscreen interface plus the powerful optimisation software provide additional ease of use.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management With the ISM 400 you can flexibly store 7“, 13“ and 15“ reels, trays, tubes, printed circuit boards, well equipped feeder, solding pastes or screen printing frames manually and monitor their insertion and extraction. The different configuration possibilities of the ISM 400 satisfy the storage needs of the most varied types of components as well as operational and consumable resources of a modern SMT production. With the help of the optional humidity control module it is possible to constantly adjust and monitor the humidity level within the system.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Compact High Speed Mounter JUKI’s JX 350 offers high flexibility and quality presented in a compact design while maintaining an attractive low price. This model handles long printed circuit boards up to 1.50 metre and is expecially suitable for cost efficient LED assemblage. On top of that the incorporated laser technology enables a highly accurate placement of diffusion lenses due to the recognition technology which identifies the main orientation of the lens.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

High Speed Compact Modular Mounter JUKI’s RX 6 is the perfect solution for companies in need of a wide variety of components and large printed circuit boards as well as having to depend on quick product changes while maintaining high quality. The high speed compact modular mounter is suitable both for small and large volumes. Due to the compact design of the machine featuring a width of only 1.25 metre the RX 6 displays a smart solution in the case of production floor space being an expense factor.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

RS 1XL For Everyone Who Wants to Assemble Larger Circuit Boards The RS 1XL combines the advantages of the RS 1 and RS 1R with the possibility of assembling printed circuit boards up to 560 mm wide (for comparison RS 1 / RS 1R max. Width 370 mm). With slightly larger dimensions than a RS 1, the RS 1XL offers the same advantages fast assembly of the smallest chips (0201 metric) to large components of 50 x 150 mm or 74 mm edge length for square components. The machine combines the properties of a chip shooter with a mounter for large components. There is no need to purchase a special machine type.duct 3 description and specification ...

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Latest Generation of Ultra High Speed Mounter The RX 7R is the first choice when it comes to the high speed assembly of a large number of printed circuit boards with smaller and smallest components. The successful concept of the RX 7 has been further developed into the RX 7R. The new placement head P16S offers increased accuracy and a longer service life. The compact machine design with a width of one meter has been retained and continues to offer maximum productivity in the smallest of spaces.

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

The traditional ALLFILM system of conventional medium and high voltage capacitors consists of aluminium foil and polypropylene, immersed completely in synthetic, flammable oil. Breakdowns in this kind of dielectric tend to result in permanent short circuits which take out the entire capacitor element, change the voltage conditions inside the capacitor and initiate a chain reaction of further failures of capacitor elements which will end up in the loss of the entire capacitor. In three-phase capacitors, this process is usually accompanied by the occurrence of phase asymmetries which may cause damage and catastrophic failure. In our MSD™ medium voltage capacitors, we are using the metallised polypropylene so well known from LV power factor correction. Instead of flat pack windings, our capacitance is formed by compact cylindrical windings, avoiding the mechanical stress at the edges of the ALLFILM flat packs.

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

The special kind of films and coating patterns used in our oil-filled E63-capacitors give them a high specific ratio of capacitance to volume and makes them extremely overvoltage proof. Very good self-healing characteristics and the integrated overpressure protection (" BAM ") ensure safe operation and controlled disconnection in the event of overload or failure at the end of operating life. Hence the E63s are interesting particularly for applications with high AC ripple currents, e.g. as smoothing or supporting capacitors in buffer storage circuits, in sensitive environment with high safety requirements. Note that the presence of an overpressure mechanism adds substantially to the self-inductance of the capacitor, and limits the surge current rating. If self-inductance and surge current are important issues, then our E50 or E53 ranges may be considered as a more adequate option.

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

The E62-3ph capacitors stand out by their high AC-voltage load capacity. They have been designed especially for heavy duty operation in extreme or sophisticated operating conditions, such as AC filtering and power factor correction in wind power and UPS applications, harmonic filtering in three-phase mains with high or unusual levels of harmonic distortion, a.m.o. Thanks to their construction, they have a very low series resistance and a small self-inductance. Our basic design principle - preferring short winding elements with comparably large diameters - as well as the use of wavecut technology in many models, serves for high rms and surge current strength. The three capacitor elements are connected in delta internally; the plant oil filling is environmentally friendly and serves for optimized heat dissipation and improved internal insulation.

Request for a quoteResults for

Printed circuits - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Passive electronic components and printed circuits (12)

- Moulding, rubber - machinery (5)

- Connectors, electronic (4)

- Monitors, computer (4)

- Laser - cutting and welding machines (3)

- Measurement - Equipment & Instruments (3)

- Building hand tools, non-power (2)

- Chemicals - Basic Products & Derivatives (2)

- Ovens, kilns, furnaces and hearths, industrial (2)

- Plastic packaging (1)

- Storage equipment and systems (1)

- Automation - systems and equipment (1)

- Automobiles (1)

- Biomedical equipment (1)

- ELECTRICAL SYSTEMS (1)

- Plastics moulding (1)

- Robotics (1)

- Sensors (1)

- Thin coating for integrated circuits (1)