- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision tools

Results for

Precision tools - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

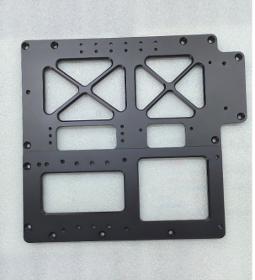

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

ENGRAVING TOOLS For engraving plastics and non-ferrous metals. The width must be ground by you, to suit your requirements.Engraving cutter and engraving stylus: For engraving plastics and non-ferrous metals. The ""typeface width"" must be sanded down in-house. Engraving cutter 60 °, point angle 60 °, number of teeth 1, spiral angle 30 ° r."

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

Special tools: The greatest possible flexibility for individual custom-made products is a matter of course for us. According to your sketch, demand-oriented solutions are created that are precisely tailored to your requirements.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

DE-BURRERS Specially developed for processing contours on CNC machines. To de-burr and chamfer metals and plastics. The de-burrers are also suitable for hard machining. Deburrer for contouring. Designed for use on CNC machines, especially for contour machining. For deburring and chamfering of metals and plastics. The de-burrers are also suitable for hard machining. Stocked by default is a point angle of 90 °. 4 - 6 mm de-burrer with 4 cutting edges, from 8 mm with 5 cutting edges.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for ""soft"" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals. SINGLE-TOOTH MILLING CUTTERS Single-tooth milling cutters are mainly used for machining ""soft"" materials. Their extra large chipping space guarantees an ideal chipping removal and high stock removal rate. MULTI-TOOTH MILLING CUTTERS Multi-tooth milling cutters are used for machining ""harder"" materials. Smoother running is achieved, as several cutting edges are always in contact. The more flutes the tool has, the smaller the individual chippings will be.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

Hard reamers 58 to 65 HRC, 1/100 rising, right-hand cutting, straight groove.

Request for a quote

ROSE PLASTIC AG

Germany

High-quality plastic cassettes in modern design. Ideal for all kinds of drill bit sets, precision tools, shank tools, special tool sets and spare parts Modular concept – cassettes can be combined with individual foam inserts or vacuum formed inserts Intergral secure locking mechanism to prevent unintended opening on impact Adjustable and flexible length stop for tools

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system Also available as spray version OKS 701

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubrication points of all kinds as slide ways, spindles, geared parts of the electronic, precision engineering and optical equipment, temporarily or permanently exposed to extreme low temperatures like in arctic climates or cold storages Roller bearing lubrication of high-speed bearings, e.g. spindle bearings, miniature or precision bearings in machine-tools or textile machines, measuring equipment, electric motors of control technology and precision mechanics Advantages and benefits Dynamic light noise proofed long-term lubrication grease Best use at arctic conditions and very high speed High efficiency through optimal formulation Multifunctional application beside the regular range of performance for greases Efficient through economical application No nameable change of consistency at low temperatures or high speeds and accordingly temperatures

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The laser cutting head FC1 is predominantly used in low to medium power lasers machines, impresses with its slim design and the related low weight. The use of aspheric lenses guarantees the best optical properties; protective glass cassettes on both the collimation side and the pressure seal below the focusing lens protect the optics from contamination. The technical design of the manual adjustment of the focus position is convincing by precision, the focus position can be precisely adjusted without tools via the generously dimensioned adjustment range of 20mm and can safely hold it without countering. The fast distance sensor allows precise control even when cutting the thinnest materials. Thus the FC1 offers excellent cutting performance at an interesting price.

Request for a quote

MICRO-EPSILON

Germany

The SGS (Spindle Growth System) 4701 displacement measuring system is developed for high speed milling machine applications. Due to high machining speeds and the heat generated, the linear thermal expansion of the precision machine tool spindle needs to be compensated for in order to keep the tool in a defined position at all times. The SGS sensor measures the expansion of the spindle caused by thermal and centrifugal force. The measurement takes places typically on the labyrinth-ring. As well as the linear expansion, the temperature of the sensor is detected and output.These measurement values are fed into the CNC machine tool as correction values, compensating for any positioning errors.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MAGDOS LA solenoid-driven diaphragm dosing pump is an indispensable tool for the precise and reliable dosing of liquids in process sequences. Available in seven different performance ranges, it offers flexible adaptation to different requirements. Thanks to the double ball valves, exact dosing is guaranteed, ensuring consistently precise results. The dosing capacity can be conveniently adjusted manually or via an analogue signal (0/4 - 20 mA), allowing easy integration into existing systems. The compact design of the MAGDOS LA requires only a minimal mounting surface, making it particularly space-saving. It can also be mounted in three different positions without additional tools: upright and left or right-orientated on the wall.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The use of gas conducting hoses (e.g. air, nitrogene etc.) requires the perforation of the cover. The PR 10.2 tool provides an easy solution for quick pin pricking of the cover. Market established UNIFLEX quality gives you a precision tool for hoses up to an outer diameter of 45 mm (1,75 inch).

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt Company offers a range of belt maintenance tools for easy removal, repair or installation of metal conveyor belts. All tools are packaged in a reusable storage sleeve to help maintain the tools precision and cleanliness.

Request for a quote

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

Ever since it was founded in 1862, the Genevabased Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models. SIP 7000/7 (4 and 5 axis) The horizontal SIP machining centers are living proof that ultraprecision is by no means a myth. Gearbox housings, spindle heads and twoaxis turntables can be machined with significantly higher levels of precision than with conventional machining centers, making them the obvious choice for customers.

Request for a quote

STARRAG GMBH

Germany

Ever since it was founded in 1862, the Genevabased Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models. SIP 5000/6 / 5000/7 The SIP vertical range is a must for all producers of parts with high levels of value creations. It enables ultraprecision positioning and the closest of dimensional tolerances for drilling and milled surfaces.

Request for a quote

STARRAG GMBH

Germany

Ever since it was founded in 1862, the Genevabased Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models. SIP 5000/6 / 5000/7 The SIP vertical range is a must for all producers of parts with high levels of value creations. It enables ultraprecision positioning and the closest of dimensional tolerances for drilling and milled surfaces.

Request for a quote

STARRAG GMBH

Germany

Ever since it was founded in 1862, the Genevabased Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models. SIP 7000/7 (4 and 5 axis) The horizontal SIP machining centers are living proof that ultraprecision is by no means a myth. Gearbox housings, spindle heads and twoaxis turntables can be machined with significantly higher levels of precision than with conventional machining centers, making them the obvious choice for customers.

Request for a quote

GRUBER SYSTEME HORST GRUBER

Germany

Universally applicable in craft, industry, transportation, business, household and leisure time. ■Reliable arrangement and protected storage of sensitive precision tools and measuring instruments ■Fixation of components, devices and other items on conveyor belts, rotary tables and loading equipments ■Safe transportation of valuable goods ■Easy to cut in any size with scissors or a knife ■Tear-resistant and unbreakable, dirt and water-repellent, easy-care, resistant to deformation in hot and cold conditions Anti-slip mats for tools provide a clear view and order in tool boxes, on assembling dollies and deposit stations.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

WESTMARK GMBH

Germany

• universal baking tool for precision work• with 4 distance rings to set the desired thickness of dough or fondant (3/8',1/4',1/8',1/16') • with graduations for measuring the width of the dough • made of easy-care, hygienic stainless steel

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Exposed linear encoders are designed for use on machines and installations that require high accuracy of the measured value. Typical applications include: Measuring and production equipment in the semiconductor industry PCB assembly machines Ultra-precision machines High-accuracy machine tools Measuring machines and comparators, measuring microscopes, and other precision measuring devices Direct drives Our standard encoders are suitable for use in a low or medium vacuum. Encoders used for applications in a high or ultrahigh vacuum need to fulfill special requirements. Design and materials used have to be specially adapted for it. For more information, refer to the Technical Information document Linear Encoders for Vacuum Technology. The following exposed linear encoders are specially adapted for use in high and ultrahigh vacuum environments. • High vacuum: LIP 481 V and LIF 481 V • High vacuum: LIC 4113 V and LIC 4193 V • Ultrahigh vacuum: LIP 481 U

Request for a quote

APEX TOOL GROUP GMBH

Germany

Precision Known for their performance, dependability and versatility, the Dotco brand is viewed as the premier line of surface-preparation tools in the industrial marketplace. With the lowest runout in the market, precision parts let the operators manufacture precision products. Ergonomics Dotco tools are designed so that their form follows their function. Simply put, these are tools that are more comfortable for the operator to use, and work with operators - not against them. Versatility By using only a few motor types, a diverse line of Dotco products have been developed to handle a wide range of applications. These tools also have a high interchangeability of parts making maintenance easier and more affordable.

Request for a quoteResults for

Precision tools - Import exportNumber of results

39 ProductsCountries

- Germany (39)

- Bonn, Düsseldorf and North Rhine and Westphalia (12)

- Frankfurt am Main and Hesse (2)

- Hannover and Lower Saxony (1)

- Kiel and Schleswig-Holstein (2)

- Leipzig and Saxony (4)

- Mainz and Rheinland-Pfalz (3)

- Munich, Nuremberg and Bavaria (8)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (6)

Company type

Category

- Precision engineering - portable power tools (6)

- Machine tools, metal machining - parts and accessories (4)

- Bending machine tools (3)

- Silicones (3)

- Labels, clothing (2)

- Precision engineering hand tools, non-power (1)

- Rolling machines (1)

- Components and parts for small household appliances (1)

- Grids, gratings and wire mesh (1)

- Grinding - steels and metals (1)

- Industrial cutting machine tools (1)

- Laser - cutting and welding machines (1)

- Machine tools - metal machining (1)

- Measurement - Equipment & Instruments (1)

- Mechanical engineering - custom work (1)

- Metal industrial presses (1)

- Perforation of rubber and plastic (1)

- Plastic packaging (1)

- Portable power sanders (1)

- Pumps (1)