- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision tools

Results for

Precision tools - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

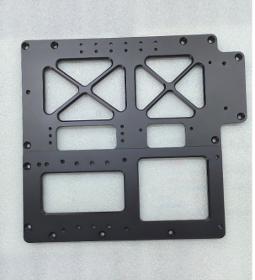

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

Special tools: The greatest possible flexibility for individual custom-made products is a matter of course for us. According to your sketch, demand-oriented solutions are created that are precisely tailored to your requirements.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

DE-BURRERS Specially developed for processing contours on CNC machines. To de-burr and chamfer metals and plastics. The de-burrers are also suitable for hard machining. Deburrer for contouring. Designed for use on CNC machines, especially for contour machining. For deburring and chamfering of metals and plastics. The de-burrers are also suitable for hard machining. Stocked by default is a point angle of 90 °. 4 - 6 mm de-burrer with 4 cutting edges, from 8 mm with 5 cutting edges.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

ENGRAVING TOOLS For engraving plastics and non-ferrous metals. The width must be ground by you, to suit your requirements.Engraving cutter and engraving stylus: For engraving plastics and non-ferrous metals. The ""typeface width"" must be sanded down in-house. Engraving cutter 60 °, point angle 60 °, number of teeth 1, spiral angle 30 ° r."

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for ""soft"" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals. SINGLE-TOOTH MILLING CUTTERS Single-tooth milling cutters are mainly used for machining ""soft"" materials. Their extra large chipping space guarantees an ideal chipping removal and high stock removal rate. MULTI-TOOTH MILLING CUTTERS Multi-tooth milling cutters are used for machining ""harder"" materials. Smoother running is achieved, as several cutting edges are always in contact. The more flutes the tool has, the smaller the individual chippings will be.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

WESTMARK GMBH

Germany

• universal baking tool for precision work• with 4 distance rings to set the desired thickness of dough or fondant (3/8',1/4',1/8',1/16') • with graduations for measuring the width of the dough • made of easy-care, hygienic stainless steel

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quoteResults for

Precision tools - Import exportNumber of results

12 ProductsCompany type