- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipe line

Results for

Pipe line - Import export

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Heavy load pipe clamps suitable for high requirements Very high safety through high cross sections High performance EPDM rubber lining Economical solution in case of high requirements We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Pipe lining made of cast polyurethane (75 Shore A). The lining is held from the outside via two flanges. Due to the extremely good abrasion resistance you have proven our linings!

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Registered design for quick-lock closing mechanism Enhanced safety through suitable material cross sections High performance noise and vibration absorption Wide grip range for all types of pipes We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

WUS WILHELM UNGEHEUER SÖHNE GMBH

Germany

Three strong profiles for many applications For economical installation of several pipe lines For assembling of cross arms and under constructions For safe load distribution on several anchors We would be very pleased to support you with all your individual questions and suggestions regarding WUS. Give us a ring or leave a message indicating the information you need. We will contact you as quickly as possible. Your WUS team

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Quickrelease couplings for water pipes, oil lines, brake and clutch lines. The quickrelease couplings are always used when a very fast installation and removal of services is required. Areas of application are motorsport and aviation.

Request for a quote

FLUX-GERÄTE GMBH

Germany

FLUX flow meters constructed on the nutating disc principle (FMC), oval rotor (FMO) or the turbine principle (FMT), provide the right solution for every application. Depending on model and overall size they can be used on e.g. FLUX drum pumps or stationary e.g. in pipe lines. Using the digital display unit FLUXTRONIC® for FMC and FMO filling and metering processes can be carried out for virtually all liquids with maximum precision and the greatest possible safety. In automatic mode there is the possibility of transmitting signals for control purposes. In this way differing processes can be regulated.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Can be used for almost any types of damage and any kind of old pipe materials Long service life for the new pipe, 80 - 100 years The old pipe capacity can be scaled up by 1 - 2 nominal sizes QuickLock: simple and safe rod connections - engage with a click, no screwing together; even small bend radii can be accessed Fast installation and set-up times Renewal of already existing pipe-line routes 40 % cost saving in comparison with open trench methods Minimal disruption to the environment and traffic flow Almost no re-instatement costs due to ground settlement, groundwater interference No road damage after pipe bursting Safe application according to latest rules and standards

Request for a quote

SPANSET SECUTEX GMBH

Germany

The noise levels in pipe and rod raising systems can be very high. A chute lined with secutex pipe modules ensures that noise levels are reduced and that surfaces are protected. The secutex material with inset perforated plates is particularly wearresistant and cushions the movement of pipes and rods very well. The cast sections are attached using drilled attachment holes. Segment sizes and joins are manufactured according to client requests.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor box 8810B made of polished stainless steel for 10 units. It can be installed at any point in the floor, as pipes are used for the line feed. Because of its low height, this version is particularly suitable for floors in old buildings. The rimless lid also closes when the plugs are inserted and is designed for sticking on floor coverings. Further equipment variants on request.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor box 8808T with 8 slots made of polished stainless steel. It can be installed at any point in the floor, as pipes are used for the line feed. Because of its low height, this version is particularly suitable for floors in old buildings. The lid is designed for the inlay of carpets, cork floors or the like, with a covering thickness of 5–7 mm, and closes even when the plugs are inserted. Further equipment variants on request.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor box 8808E made of stainless steel. Inside there are two aluminum equipment supports for 4 units each. It can be installed at any point in the floor, as pipes are used for the line feed. Because of its low height, this version is particularly suitable for floors in old buildings. The stainless steel lid, surface polished, closes even when the plugs are inserted. Further equipment variants on request.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor box 8808B made of stainless steel. Inside there are two aluminum equipment racks for 4 units each. It can be installed at any point in the floor, as pipes are used for the line feed. Because of its low height, this version is particularly suitable for floors in old buildings. The rimless lid also closes when the plugs are inserted and is designed for sticking on floor coverings. Further equipment variants on request.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For mounting screwed connections, e.g. at combustion engines, threads on pipe fittings, flange joints and fittings of superheated steam lines, exhaust pipe and combustion chamber screwed connections, gas and oil burner mounting bolts To prevent burning together, seizing or rusting-on of screwed connections at water influence Suitable for brake systems of vehicles Advantages and benefits Excellently suited for preventing binding of threads exposed to high temperatures, corrosive environments and moisture Highly effective due to high level of pressure absorption Excellent corrosion protection Absolutely resistant to fresh water and sea water Extremely adhesive No classification according to (EG) No. 1272/2008 For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Use a brush, spatula or similar

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quote

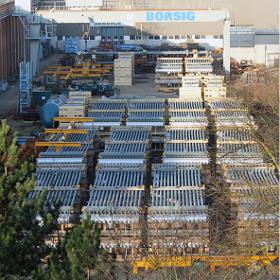

BORSIG GMBH

Germany

Transfer Line Exchangers (tunnelflow and linear quench coolers) from BORSIG are used in plants producing ethylene, an important starting material for plastics manufacturing. In these ethylene plants our transfer line exchangers are rapidly cooling down the so-called cracked gas in order to obtain the optimum yield of ethylene. BORSIG Transfer Line Exchangers are the result of more than 50 years experience and about 7,500 units have been supplied worldwide between 1965. BORSIG Process Heat Exchanger GmbH has developed two design types of quench coolers, reflecting the customer`s plant concept: 1. "Tunnelflow" transfer line exchangers (shell & tube design) 2. BORSIG "Linear" transfer line exchangers (double-pipe design)

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Installation of new PE-100 RC pipes as a pipe string (long pipe) Pipe installation via a starting manhole from 1 m diameter Installation length up to 150 m New pipes OD 192, 242 and OD 292 Tight in pipe means only minimal cross-section loss and small annular space without filling The hydraulic capacity of the new pipe can be in-creased by using pipes with smooth interior lining House connections can be connected without the need for trenches

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you a wide range of pneumatic conveying systems, taking into account the substances, the conveyor section and the feed rate. Our product range covers pneumatic thick stream conveying, thin stream conveying, dilute phase conveying as well as plug conveying in the positive pressure and vacuum range. Pipe or hose lines enable vacuum conveyance or pressure conveyance of bulk materials or liquids by means of positive pressure or vacuum. All conveying systems can be customised to meet your specific needs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

Solution for partially filled pipes The TIDALFLUX 2000 flow sensor with integrated and non-contact capacitive level measuring system provides accurate flow measurement in partially filled pipes. TIDALFLUX is designed to measure reliably between 10% and 100% of the pipe cross section. The integrated level sensors in the liner are in no contact with the liquid and are therefore insensitive against fat and oil floating on the surface.

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET One Dot Systems (EDS) are particularly well suited to very fine dot and line markings. The dot size is configured by selecting the nozzle size and by varying the material pressure, and the stepless setting on the controller. Applications — for quality assurance you can mark products with a dot to be recognized as either good or bad (use automatic camera recognition) — colored line marking for pipes, profiles and endlessly manufactured products (e.g. extruded goods) — applying oils, separating agents, soaps or process water — welded seam marking in the manufacturing of metal profiles — applying fragrances to cosmetic samples

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flow Sight Glass Type Type N880-SOW with pipe – socket – weld connection Use: The flow indicators are used for optical control of fluids and gases, for horizontal and vertical pipe-lines. Also available with internal spinner or flap.

Request for a quote

MPT DOSING GMBH

Germany

Why streaming current? The charge potential of particle surfaces of the solids in a disperse system plays an important part in water treatment procedure. Due to the unidirected charge of these particles, an approach is prevented. The particles are stabilized in its solution. A separation of these particles will be easier, if the surface charge can be reduced and the particles can form bigger flakes and bigger units. In order to control this process, it is important to measure the surface potential of the solids. What is streaming current? If you fix two electrodes in a pipe-line carrying a suspension, one in the centre and the other one near the pipe-line wall, you can measure a current. This is caused by the separation of the counter ions from the solids. The counter ions will be carried with the turbulent flow, and the solids tend to stick to the pipe-line wall by adsorption and by 'van-der-Waals' forces. The measured current is named current caused by flow or Streaming-Current.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Tubular sight glasses Type 620 with Flange connections Use: Sight glass – Tubular type with flanges on both sides, to use in either horizontal or vertical pipe lines for optical control of liquids and gases. Flanges matching DIN 2632 / DIN 2633 (PN 10/16) up to DN 150, DIN 2632 (PN 10) above.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

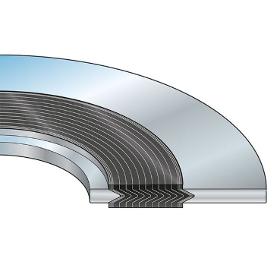

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple product viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION HMI and SCADA with touch screen system Mixer tank with raw material vacuum sucking technology Can handle multiple viscosity from high to low Double jacket mixer tank for heating and cooling system with pressure and vacuum technology Product certification transferring pump Flowmeter system Exchangeable blades; multiple blades types and design has been manufactured to conform the product types and textures Piping gel cooker machine; Time and speed can be adjusted up to the product needs Automatic product transfer system can be managed with the PLC screen Buffer tank transferring system; cooked products will be transferred from cooker by a homogenizer sucking system Homogenizer with a compact design; with exchangeable heads (conforming the product type).

Request for a quote

INOEX GMBH

Germany

WARP 100 is an inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a gapless measurement. This is particularly important for pipes with high quality requirements, such as pressure or gas pipes. The maximum line speed for 100% coverage is up to 11.8 m/min. WARP 100 is available in three sizes and can be used for measurement in the diameter range from 25 to 630 mm. Measured variables such as wall thickness, diameter, ovality, eccentricity as well as process conditions (e.g. sagging) are precisely recorded, documented, and further used for automatic process control. Other advantages/features: — Measurement with 100% pipe coverage in diameter range from 25 to 630 mm (three sizes) — Wall thickness range from 2 up to 125 mm (depending on material) — Detection of thin sections within the tube — 100% documentation of production according to specifications

Request for a quote

INOEX GMBH

Germany

ECCO is the efficient solution for fast pipe centering. Especially for thick-walled large pipes, with low line speeds and high mass throughput, the start-up process is difficult, time-consuming, and associated with high raw material costs. ECCO makes it possible to measure the wall thickness distribution shortly after the pipe calibration. The ultrasonic sensors, which are mounted directly behind the calibration sleeve in the vacuum tank, are pneumatically and flexibly moved up to the respective pipe geometry after line start-up and adapted to the pipe. Further advantages/features: — Significant reduction of start-up scrap — Fast pipe wall centering — Fast reaching of product specifications after product start-up — Fast detection of product variations — Uniform wall thickness distribution — Suitable for PE, PVC, and PP with an outside diameter from 200 mm (wall thickness range PE from 8 - 140 mm, wall thickness range PVC and PP from 8 - 40 mm)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

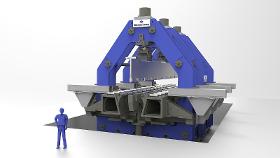

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. Pipe element with flare for melting water line

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Pipe cleaning systems are designed according to the processing requirements. Here the machine line length changes equivalent to the throughfeed speed. An alkaline cleaning station that adjusts to the individual degree of soiling of the pipe surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line.

Request for a quoteResults for

Pipe line - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Electronics - import-export (4)

- Flow meters (3)

- Precision measuring instruments (2)

- Silicones (2)

- Coupling screws (1)

- Food industry - machinery and equipment (1)

- Forming - steels and metals (1)

- Goods handling systems, continuous (1)

- Heat exchangers (1)

- Marking machines (1)

- Pipe and tube fittings - ferrous metal (1)

- Pipes and tubes, aluminium (1)

- Plastic material processing (1)

- Tapes, adhesive (1)

- Video equipment, professional (1)

- Water distribution (1)