- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- petrochemical industry

Results for

Petrochemical industry - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

For both onshore and offshore applications we develop technical heating solutions for the thermal treatment of gaseous and liquid media as well as for solids of all kinds.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the assembly parts of air valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

BORSIG GMBH

Germany

BORSIG supplies synthesis gas boilers for gas pressures up to 350 bar (35,000 kPa) and steam pressures up to 160 bar (16,000 kPa). They are used in the synthesis gas loop of ammonia plants. The boilers are equipped with U-tubes and can be mounted both in the vertical as well as in the horizontal positions. With both designs, the steam drum can be integrated into the boiler if requested by the customer. At the same time, a feed water pre-heater can be installed in the boiler when required.

Request for a quote

BORSIG GMBH

Germany

BORSIG patented steam superheaters are suitable for steam pressures of up to 160 bar (16,000 kPa). The steam superheaters are arranged direct in line after the waste heat boilers which are connected to the secondary reformer or reformer – depending on the process. The steam superheater can be provided as two stage or one stage, horizontally or vertically arranged. The final design arrangement is determined by the process requirements. We have delivered steam superheaters for superheating saturated steam at a pressure stage of 12,500 kPa from 328 °C to 531 °C by cooling down process gas from 723 °C to 355 °C.

Request for a quote

BORSIG GMBH

Germany

BORSIG manufactures reformed gas waste heat boilers for more than 50 years. We supply reformed gas waste heat boilers for gas inlet temperatures of up to 1,200°C and steam pressures of up to 160 bar (16,000 kPa) for petrochemical industry (ammonia plants, methanol plants, hydrogen plants, ethylene plants, styrene plants, MTBE plants, oxo-alcohol plants, direct reduction iron plants, coas gasification plants, gas to liquid plants, and others. Every reformed gas waste heat boiler is designed and manufactured exactly in accordance with the customer´s individual requirements. BORSIG offers two different designs: 1. Reformed gas waste heat boilers with BORSIG´s thin stiffened tube sheet design 2. Reformed gas waste heat boilers with thin flexible tube sheet design.

Request for a quote

BOURDON HAENNI GMBH

Germany

Bourdon takes mechanical pressure monitoring into the digital age This innovative device fits to any comprehensive platform for machine and process monitoring as well as the preventive maintenance of equipment which is supported by a LoRa wireless protocol. Key applications include pressure measurement and monitoring for oil refineries, petrochemical industry and biodiesel plants. More predestined applications are in waste and water treatment, power generation and transmission, general process industry, building services and civil engineering. The right choice when industry grade wireless pressure measurement and monitoring is required

Request for a quote

BORSIG GMBH

Germany

Reducing energy, saving resources and safe processing have high priority in the chemical and petrochemical industry today. Our advanced liquid separation technologies are targeted to treat hydrocarbon based or solvent containing process streams and provide valuable tools for process intensification. Typically organic liquid streams are processed by conventional thermal unit operations that consume high amounts of energy, operate at high temperatures and/or require additional chemicals for efficient separation. Our membrane based solutions offer potent alternatives or additions for new processes and a valuable tool for the retrofit of existing unit operations. Our product range: - BORSIG Organic solvent nanofiltration - BORSIG Pervaporation - BORSIG Process development services

Request for a quote

BORSIG GMBH

Germany

BORSIG offers comprehensive services for the power engineering, chemical and petrochemical industries as well as oil, gas and water supply. From our facilities Berlin, Gladbeck and Hamburg our exellently networked global team of engineers and technicians provide you with competent, fast and reliable support. We have decades of experience in planning, performing and implementing all kinds of assembly, manufacturing and service tasks. We rectify malfunctions and procure any required spare parts. We support you in the planning, delivery and installation of new components in your systems, modification, inspection and maintenance of existing components provided by us or third parties, and we also offer troubleshooting within the framework of a 24-hour standby service. Our services comprise: - Pressure vessels: Field service and repairs - Engineering - Boiler service - Piping - Workshop facilities for new production and overhaul of vessels

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Typical Fields of Application are in the chemical, petrochemical, railroad and shipbuilding industries, in the machine and industrial equipment construction. CSN® circulation heaters are manufactured in close coordination with our customers from a few watts to the megawatt range, a division in individual circuits is made according to customer’s requirements. Equipment for installation in hazardous areas we produce in protection class „Ex d“, „Ex de“, „Ex e“. On request, CSN® circulation heaters are supplied with optimized process controls. Please contact us to talk about the most appropriate control system. Schniewindt is certified by the Lloyd’s Register to produce equipment according to the Pressure Vessel Directive 2014/68/EU and a certificate from TÜV (Technical Monitoring Agency) certifies that we meet the prerequisites for welding procedures according to AD 2000 Merkblatt HP 0 / DIN EN 7293.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Mixing of substances and chemical reactions are closely interconnected. The way in which different reagents are mixed together can have a significant influence on product quality, product yield, or even on the resulting product itself. Stirred reactors are used in the chemical industry for a range of applications. They can be used for reaction, extraction, distillation, crystallization, and other processes. Depending on the reactor process and operating mode (continuous, semi-batch, or batch operation), the agitators used can be subjected to varied demands. In the petrochemical industry, emulsification, absorption, desalination, alkylation, or neutralization processes are commonly found; lubricating oils must be homogenized or sludge oils suspended. For this wide variety of mixing tasks, Geppert offers tailor-made agitators to satisfy operational and customer requirements.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

The LevelEx is available in sizes M16 to M63 or with NPT threads from 3/8" to 2 1/2". PFLITSCH manufactures the cable gland bodies from bright brass, galvanised nickel-plated brass and corrosion-free stainless steel. The LevelEx achieves protection class IP 66 or IP 68 and corresponds to the ignition protection types flameproof enclosure "Ex-d" and increased safety "Ex-e". With its wide temperature range of -60 °C to +130 °C and approvals according to ATEX and IECEx, the LevelEx can also be used under extreme environmental conditions. For armoured cables, PFLITSCH offers the LevelEX AC. It has the same technical quality as the proven LevelEx for non-armoured cables. In addition, it convinces with additional properties. For example, it scores with an innovative design for accommodating armoured cables: Two opposing windows in the armour clamping allow the correct seating of the cable armour to be checked immediately.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for agitated and corrosive liquids The OPTIWAVE 7400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in harsh environments like tanks with agitators containing corrosive media. It is particularly designed for continuous, non-contact level measurement under extreme conditions prevalent in the chemical, petrochemical or oil and gas industry. The device features Metallic Horn antennas as well as PTFE and PEEK Drop antennas for measuring distances up to 100 m / 328 ft. The Drop antennas are perfectly suited for aggressive liquids in tanks. In applications with toxic and dangerous products, this radar device can be equipped with a Metaglas® second sealing barrier.

Request for a quote

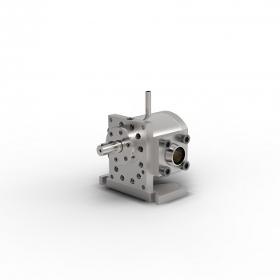

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel metering gear pump for the delivery of chemical raw materials for the production of pharmaceutical products. CHEM metering pumps are also used to pump isocyanate, sulphuric acid, polyol or essential oils. With the appropriate combination of materials, many critical applications can be realized and a variety of low-viscosity fluids can be pumped. The range of applications extends from classic transfer and metering tasks in the chemical and pharmaceutical industry to the pumping of monomers, oligomers and prepolymers in polymer production. These chemical pumps are suitable for even the most difficult tasks and impress with their reliability and dosing accuracy in both vacuum and high-pressure applications. Typical applications for this pump type are in the chemical, cosmetics, food, petrochemical and polymer industries

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

The control of the quantities of liquid products in the mineral oil industry and in the chemical and petrochemical industry requires volume-measuring instruments, which are adjusted to the special operating conditions and characteristics of the transported materials being measured both with respect to design and materials used. Oval wheel meter of the OaP series meet these requirements. They are used for measuring liquid raw, intermediate and finished products such as liquefied gases, gasolines, heating oils, lubricating oils, transmission oils, solvents, bitumen, alkaline solutions, acids and other chemical liquids. Meters of this series are employed for the filling of tank trucks, rail tank cars and tanker ships, in pipeline operations and the process technology for the determination f balance sheets of materials such as heating oil consumption and the control of burners etc. Due to the high measuring accuracy and operational safety, oval wheel meters from this series are...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % virgin PTFE, modified and filled with Barium sulfate Characteristics Protected against cold flow Excellent recovery Excellent chemical resistance in caustic applications Reduced leakage rates compared to other filled PTFE gaskets under the same gasket stress. Technical parameters pH 0 - 14 Temperature: t = -180 … +230 °C, short term up to 260 °C Pressure: p = 55 bar Article code / Thickness WHITE 08 / 0.8 mm WHITE 10 / 1.0 mm WHITE 15 / 1.5 mm WHITE 20 / 2.0 mm WHITE 30 / 3.0 mm Main application Steel-, Glass-, Ceramic-, glass lined or plastic flanges on pipework Vessel Container Reactors Suitable for Chemical and Petrochemical industry Approvals TA-Luft Form of delivery Gasket sheet size of 1,500 x 1,500 mm in thickness of 0.8/1.0/1.5/2.0/3.0 mm or cut gaskets according to drawing or EN and international Standards, special dimensions on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Modified PTFE reinforced with special silica filler Characteristics Protected against cold flow Excellent recovery Very good in applications with varying temperatures Reduced leakage rates compared to other filled PTFE gaskets under the same gasket stress. Technical parameters pH 0 - 14 Temperature: t = -180 … +230 °C, short term up to 260 °C Pressure: p = 55 bar Article code / Thickness FAWN 05 / 0.5 mm FAWN 10 / 1.0 mm FAWN 15 / 1.5 mm FAWN 20 / 2.0 mm FAWN 30 / 3.0 mm Main application Steel or other metal flanges on pipework Vessel Container Reactors in higher temperature applications. Suitable for Chemical and Petrochemical industry Approvals TA-Luft Form of delivery Gasket sheet size of 1,500 x 1,500 mm in thickness of 0.5 / 1.0 / 1.5 / 2.0 / 3.0 mm or cut gaskets according to drawing, or EN and international Standards, special dimensions on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High Temperature Gasket of Expanded Flexible Graphite with Stretchmetal Characteristics Expanded graphite sheet gasket with Stainless Steel stretch metal reinforcement and a purity of 99 %. Practically no cold flow or creep under temperature. Non hardening Excellent in use with cycling temperatures. Blow out safe due to 3 dimensional reinforcement matrixes Optimized transfer of sealing stress Safe use even with small sealing width Minimized risk of separation known from multilayer reinforced gasket sheets. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, n oxidizing atmosphere +450 °C Pressure: p = 200 bar Main application Universal use as problem solver in all industries when demanding higher operation safety and sealability especially in older plant equipment. Suitable for Chemical industry Petrochemical plants Pharmaceutical industry Power plant technology Paper industry Sugar industry Approvals DVGW BAM TA Luft FIRE SAFE API 607 on request Form of...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 5 Prophit High Temperature Gasket of Expanded Flexible Graphite with and without reinforcements Characteristics Temperature range in inert environment up to +3000 °C (attention: reinforcement inserts cause temp limits) Permanent elasticity, resilience approx. 10 % Non ageing - does not contain binding compounds High pressure resistance Radiation resistance and excellent media resistance Main application Flanges Sight glasses Valve bonnets Pipe flanges Suitable for Chemical industry Petrochemical refineries and steam production Pharmaceutical industry Power plant technology Paper industry Sugar industry Form of delivery Sheets or custom die cut rings With inner or/and outer crimp: mat. 1.4571 0.15 mm thick, seamless pressed Other materials and designs on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed ring-set made of expanded graphite and reinforcement to protect against extrusion Characteristics Packingset made by combining two expanded Graphite grades and designs in order to avoid blow out and extrusion and as well enhance the sealability of this valve sealing set. The set was tested and approved by the AMTEC GmbH Lauffen in Germany. The leakage parameters of 8.6 x 10-3 mbar · l/(s·m) complies with the VDI 2440 at +400 °C, which specifies a maximum allowed leakage of 1.0 x 10 -2 mbar · l/(s·m) (test media helium) and is therefore recommended as a high grade seal system. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 160 [bar] Temperature without LiveLoading: t 400 °C Temperature with LiveLoading: t 400 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Refineries Approvals TA Luft / VDI 2440 Certificate

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed Packing Set of specially impregnated PTFE fiber packing Characteristics Ring set made of pure PTFE packing and PTFE compound bull rings fulfills with a tested leakage rate of 4.2 x 10 -5 mbar · l/(s·m) the leakage criteria according to VDI 2440 +200 °C with a maximum allowable leakagerate of 1 x 10 -4 mbar l/(sm) and is suitable for temperatures up to +200 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +200 °C Temperature with LiveLoading: t +200 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Power plant technology Chemical industry Petrochemical plants Approvals TA Luft / VDI 2440 Certificate

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-compressed Packing set of specially impregnated PTFE fiber packing Characteristics Ring set made of pure PTFE packing fulfills with a tested leckage of 6.3 x 10 -6 mbar · l/(s·m) the leakage criteria according to VDI 2440 +200 °C with a maximum allowable leakagerate of 1 x 10 -4 mbar l/(sm) and is suitable for temperatures up to +200 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +200 °C Temperature with LiveLoading: t +200 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Suitable for Chemical industry Petrochemical plants Approvals TA Luft / VDI 2440 Certificate EU 10/2011 / EG 1935:2004 FDA

Request for a quote

KITO ARMATUREN GMBH

Germany

For installation into pipes to protect containers and components against stable detonation of flammable liquids and gases. Tested and approved as detonation flame arrester type 4. Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an maximum operating temperature of 60 °C must not be exceeded. Provided with one temperature sensor (PT 100) the armature is certified against short time burning from one side. The installation is not dependent on the position and both directions of flow are possible. During installation, please observe the direction of detonation and the indication „protected side“.

Request for a quote

KITO ARMATUREN GMBH

Germany

For installation into pipes to the protection of vessels and components against stable detonation of flammable liquids and gases. Tested and approved as detonation flame arrester type 4. Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60 °C must not be exceeded. All sizes are tested against “stabilized burning” and withstand this up to a max. burn time BT ≤ 30.0 min. To detect a “stabilized burning” a temperature sensor must be installed at each endangered side. Mounting is acceptable in any position, in horizontal as well as in vertical pipes.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C .

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. Product Range: - DVGW tested, see separate brochure - Punched, cut seals - Plates, foils - Semi-finished items - Form articles Benefits: - Highest chemical resistance - Insoluble and does not swell in organic or anorganic solvents - Resistant to the weather - Temperature range -190 to +250 °C - Highly anti-adhesive, does not stick - Resistant to hydrolysis Common fillers: - Quartz - Glass - Carbon / Graphite - Bronze - or without filters Fillers reduce the cold flow, lead to higher resistance to temperature and media, improve thermal conductivity and increase resistance to abrasion and pressure levels.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quoteResults for

Petrochemical industry - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Petrochemical industry - installations and equipment (7)

- Cocks and valves for petroleum and petrochemical industries (6)

- Seals (2)

- Steel, special (2)

- Measurement - Equipment & Instruments (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical catalysts (1)

- Air-conditioning systems, vehicles (1)

- Energy - production plants and equipment (1)

- Filters, liquid (1)

- Gas and oil - exploitation (1)

- Gear pumps (1)

- Grids, gratings and wire mesh (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Shearing machine tools (1)

- Steel (1)

- Water-heaters, domestic (1)