- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pallet containers

Results for

Pallet containers - Import export

GRUBER SYSTEME HORST GRUBER

Germany

Vielseitigkeit, Stabilität, Raumgewinn, sicheres Lagern und Transportieren sind Trumpf! Jumbo-Palettencontainer zeichnen sich durch besondere Formstabilität und weitgehende Kälte- und Hitzebeständigkeit aus. Die aus hochwertigem Polyethylen gefertigten Container sind physiologisch einwandfrei und dabei bequem und leicht zu reinigen. Gegenüber herkömmlichen, stark verrippten Behältern haben die spezifisch leichtgewichtigen, aus einem Stück gespritzten Jumbo-Palettencontainer eindeutige Vorteile: ■ Hohe Nutzlast: 500 kg ■ Hohe Stapellast: 4500 kg ■ Stabile, teilweise doppelwandige Konstruktion, in den Ecken zusätzlich verstärkt ■ Im Innenbereich abgerundete Ecken, somit hygienisch vorteilhaft maximales Nutzvolumen von 360 bis 670 Liter ■ Ausführungsvarianten mit Füßen oder Kufen, auf Wunsch mit Lenkrollen, 125 mm Ø, mit und ohne Feststeller ■ Stülpdeckel mit Stapelrand; geeignet für Einzelabdeckung und Blockstapelbildung durch formschlüssig und wasserabweisend gestaltete Oberseite

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labelling machine for labelling drum pallets IBC Conatiner All chemicals are subject to mandatory classification and labelling before they are placed on the market. Often, several labels (product label, hazardous goods label and logistics label) are used up on the containers or drum pallets. Labelling can take place in a continuous flow or at a standstill. Vacuum belts are used for transferring labels to the drum, which can process different label sizes with the appropriate special vacuum plate. The IBLM labeller can be used as a stand-alone labeller or integrated into existing production lines and filling lines.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

GSW SCHWABE AG

Germany

No more strenuous bending when taking parts out of a container Increases production while reducing sick leave Heavy containers and skeleton containers can be transported as easily as with a pallet truck ´ Container can be tilted hydraulically with a footpump in an angle of 0 90 degrees to achieve the best working position

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The Lader 7.0 generation underwent thorough revision. Today it is one of the most innovative, most efficient and safest container and pallet laders in the market.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

Due to its enormous flexibility and manoeuvrability, this multi-talent can be used as a loader to load aircraft and as a container and pallet transporter.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. To handle air cargo container or pallets including adjustable driven ram protection, walkways, a winch and hydraulic side-shift function. Dimension: 830 x 4230 mm Operating stroke: 1200 mmm Rated load: 14000 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. 10 feet workstation incl. load cells and fixed stops in front of the running rollers. Used to pack or unpack aircargon container or pallets. Dimension: 3200 x 2200 mm Operating stroke: 2100 mmm Rated load: 7000 kg

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

With the FFS 23 (coordinate filling system), FRICKE presents another innovation that sets new standards Designed in a robust stainless steel construction and prepared for automatic bunghole detection, this system guarantees not only accurate, calibratable filling but above all: high efficiency. Because, whilst in the case of conventional machines the container is guided to the valve, the FFS 21 (coordinate filling system PK) does exactly the opposite! his means an immense time saving, especially for pallet filling of different containers. The relatively light valves move at an enormous speed and are easy and fast to clean due to only three components which have direct contact with the material. Thus, changeover times are reduced to a minimum. What sounds like intensive handling and complicated can be easily implemented by one person in only three steps: — Position the pallet (below the system) — Documenting the container positions via 'teach in' — Start the filling process

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers, such canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibrated above level filling of several containers on one pallet ■ thread-cutting, non-dripping filling valve ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fast filling of multiple containers on a single pallet. Filling station with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. For the filling of bunghole containers, e.g. canisters, bunghole drums or IBCs directly on the pallet. Below level filling, coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ an almost foam-free, calibratable below level filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of non-frothing liquids e.g. chemical liquids or oils. For the filling of open bunghole containers, such as canisters, bunghole drums or IBCs (Intermediate Bulk Container), directly on the pallet. Below bunghole filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ an almost froth-free, calibratable below bunghole filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

POLY-PACK VERPACKUNGS-GMBH & CO. KG

Germany

PE covering hoods and PE liner sacks (e.g, for EURO, CHEMICAL and SPECIAL pallets and larger containers) Width: between 1000 and 3000 mm Length: between 500 and 4000 mm Thickness: between 0.03 and 0.25 mm The most extensive standard range of PE products from North Rhine Westphalia

Request for a quote

FATH GMBH

Germany

Protects Kanban cards from dirt and abrasion KANBAN CASE for SLC boxes (small load carrier), Euro containers, Kanban boards etc.; for insertion, tear-resistant and stretchable transparent film with resetting capacity, scanner-compatible various designs and sizes: open at the side or top transparent, yellow, red, blue, green, grey, black, white material: PVC KANBAN-HOLDER for holding kanban cards, label sleeves or documents of all common formats: transparent and reusable — CLIP; universal for sticking to many surfaces from plastic containers to wooden pallet feet — OVERHANGING; for hanging over small load carriers and other containers, containers remain stackable — SELF ADHESIVE; for flexible adhesion even on uneven surfaces, can be removed without leaving residues, can be reused several times on load-bearing surfaces thanks to multi-use property — MAGNETIC; for magnetic attachment to metallic surfaces

Request for a quote

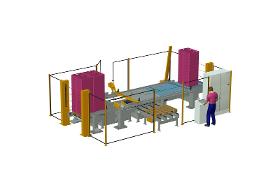

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVEXX SOLUTIONS GMBH

Germany

Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units. The ALS 209 applies labels with a very large width (up to 229 mm or 9 inches) and is extremely precise and reliable, even in harsh environments. Moreover, due to its extreme compactness, the ALS 209 can be used in a very flexible way. And thanks to its optional tandem function, down time when changing the material is a thing of the past. With the ALS 209, NOVEXX Solutions provides a very efficient and at the same time economically profitable labeling system. Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units.

Request for a quote

MIAS MASCHINENBAU, INDUSTRIEANLAGEN & SERVICE GMBH

Germany

Tried and tested: MIAS invented this telescopic fork in the 1960s, and it has undergone continuous further development ever since. Robust, flexible, low maintenance. For pallets and skeleton containers with a maximum weight of up to 1,500 kg. Highlights: - Tried and tested a thousand times over - Small overall size - Optimal static and dynamic load-bearing capacity - Low level of bowing under load - Low maintenance due to positive-locking, double-row stationary gear - Can be used at temperatures as low as -30°C

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Traporol driven rollers are available in different versions depending on the type of drive. Whether single or double chain sprocket, drive via bead and dual bead or tooth belt drive. At Traporol you will find just the right solution for every application. This is how your intralogistics runs smoothly – regardless of the size and weight of the conveyed goods. Decisive criteria when choosing driven rollers are the weight and condition of the conveyed goods. In particular, conveying pallets and containers requires especially robust rollers, with a galvanized steel surface, for example.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Economic + maintenance friendly articulated arm robot alternative • Flexible plastic case + carton tray stacking heights • Changeover times for gripper and format parts are eliminated due to automatic format changeovers • Unit performance can be expanded through additional stackers • Use of Euro pallets, Duesseldorfer half pallets + industrial pallets Within limited space situations the fully automatic stacking and palletizing unit is the first choice for flexible handling of all market formats. The slimly designed Stacker is economical + mainteance friendly when it comes to stacking plastic cases, meat crates, nestable carton and trays, mixed pallet commissioning or bakery baskets without pallets . Product and format changeovers are software controlled and require no tools. The Stack Palletizer is ideally suited for palletizing pre-stacked containers and the shuttle system allows for collecting different product stacks and creating mixed product pallet loads.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

Results for

Pallet containers - Import exportNumber of results

23 ProductsCountries

Company type