- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- non-permanent

Results for

Non-permanent - Import export

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a samarium-cobalt magnet in a steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a threaded socket with an internal thread.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a neodymium magnet in a steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has no hole and is usually glued or pressed in.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a neodymium magnet in a steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a 8 mm threaded socket with an internal thread. It is characterized by a force of 140 N. The diameter is 20 mm, the total height of the flat gripper is 15 mm.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a hard ferrite magnet in a steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a 10 mm threaded socket with an internal thread. It is characterized by a force of 125 N. The diameter is 40 mm, the total height is 18 mm.

Request for a quote

KAISER-MOTOREN GMBH

Germany

PMmotors with rotorcage for line start The pmexcited reluctance motors are an alternative to the reluctance motors and can be used in identical applications typical for synchronous motors.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Kendrion (Aerzen) Mini Permanent magnet brakes open electromagnetically. The braking torque without backlash is generated by permanent magnets. The brakes can be installed in any position. High quality magnets ensure safe functionality. The rated torque is achieved immediately at the time of delivery without any running-in procedure.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The High Torque series combines the well-known properties of permanent magnet brakes - Due to a re-design of the magnetic circuit, it features further advantages such as a higher torque at identical size and power consumption, high torque constancy throughout the complete service life and an extended temperature range. The High Torque brake is designed to operate dry. The force generated by a permanent magnetic field is utilised to produce the braking effect. To neutralise the braking action, the magnetic flux of the permanent magnets is cancelled by an alternate electromagnetic field (electromagnetically released system). The zero backlash connection between the armature and flange hub ensures zero backlash transmission of the brake torque to the machine shaft (e.g. motor shaft) and reliable release of the High Torque brake with zero residual torque. Thanks to these features, High Torque brakes are ideal for servo motor applications.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The PM Line includes permanent magnet brakes in which the braking force is generated by a permanent magnetic field. The brake thus works in a de-energized condition and fulfill the following functions: Holding, positioning and emergency stop. The neutralization of the braking force is effected by the counteracting electric field, granting a high degree of security, even in the case of power failure. Permanent magnet brakes are characterized by a secure, residual-moment-free lifting in any position, and by a backlash-free transfer of the braking torque. Therefore, they are ideal for servo motor applications.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXE-R electro-permanent lifting magnets that can lift round material or, both round and flat material, we manufacture from our FXE basic models with pole shoes that can lift the customized diameter band widths, individually or in layers. Electro-Permanent Lifting Magnets FXE Electro-Permanent Lifting Magnets from Flaig Magnetsysteme have been setting standards for over 20 years Electro-Permanent Lifting Magnets are the best choice if: the load to be moved is too large for permanent magnets the lifting magnet must be operated and controlled ergonomically the geometry of the load does not fit permanent magnets the lifting magnet must be remote controlled and possibly load adjustable the load capacity is too large in relation to the material thickness for permanent magnets

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Equipped with pole type 50+ in long narrow design and a maximum load capacity of 400/600/1000 kg, which is achieved with material thicknesses from 15mm, these easy-to-guide and operate devices are recommended for lifting battens, rails, pipes, beams and bars. Also using pole extensions, which make it easier to position the magnets on long narrow bars.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXE electro-permanent lifting magnets are equipped with on-board control technology for direct connection to mains voltage - the fast, user-friendly plug & play solution for loads from light to super heavy. Different pole types are available, depending on the material thickness and surface to be moved.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXE-MH electro-permanent lifting magnets are especially suitable for transporting slabs and blocks. The electro-permanent modules type MH are designed to safely lift large loads with a large air gap. Electro-Permanent Lifting Magnets FXE Electro-Permanent Lifting Magnets from Flaig Magnetsysteme have been setting standards for over 20 years Electro-Permanent Lifting Magnets are the best choice if: the load to be moved is too large for permanent magnets the lifting magnet must be operated and controlled ergonomically the geometry of the load does not fit permanent magnets the lifting magnet must be remote controlled and possibly load adjustable the load capacity is too large in relation to the material thickness for permanent magnets

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXE-M electro-permanent load lifting magnet modules can be combined with MCF control units to form modular load lifting systems. For example, a single FXE-M module with an MCF 1-channel control unit can be used on the crane of a flame-cutting machine, or 4 FXE-M modules, controlled together or individually by an MCF 4-channel control unit, can operate in a fully automatic sectional steel plant. In use on cranes, manipulators, conveyors and robots, FXE-M modules have proven themselves thousands of times over. FXE-M modules are manufactured using monoblock technology and are extremely stable. As with the other products in the FXE series, a choice can be made between different pole types in order to use the appropriate magnet module depending on the load, dimensions and surface.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

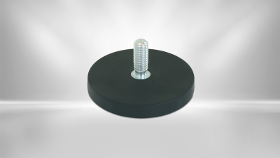

Flat gripper with a neodymium magnet in a rubber-coated steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a central internal thread.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a neodymium magnet in a rubber-coated steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a threaded pin with an external thread.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Flat gripper with a neodymium magnet in a rubber-coated steel pot. The housing increases the adhesive force of the permanent magnet. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The flat gripper has a threaded pin with an external thread.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

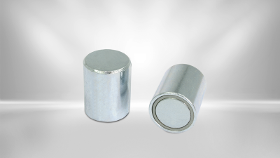

Rod gripper with a neodymium magnet in a steel housing. The maximum adhesive force is achieved when the entire surface is placed on a metallic surface. The rod gripper has no thread and is usually glued or pressed in.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

In its sensor housing, the combiSENSOR combines two displacement sensors. This unique sensor concept enables one-sided thickness measurement of electrically non-conductive materials on metallic objects. Its field of application is the thickness measurement of plastic film or of plastic coating on metal plates. The eddy current sensor penetrates the plastic layer and measures the distance to a metallic material underneath it, e.g. a metal plate. The capacitive sensor synchronously detects the distance to the plastic material. The thickness is determined based on the difference of both sensor signals.

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

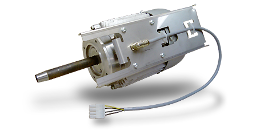

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 40 N – Permissible shaft loads (radial): 100 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: feasible

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The permanent holding magnets achieve a holding force of up to 35,000 N in the de-energized state and are designed for long holding of magnetic workpieces. When the DC-excited coil is switched on, the permanent magnetic field on the holding surface is neutralized and the workpiece to be held can be removed. The electromagnet holds loads even in the event of a power failure and only needs to be energized briefly to release the workpiece. It is characterized by its energy efficiency and high holding forces. The permanent holding solenoids are available in different sizes with forces between 8 and 3,500 N.

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated and chromized – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 110 N – Permissible shaft loads (radial): 300 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: feasible

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated and chromized – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 40 N – Permissible shaft loads (radial): 100 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: feasible

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes General data – Nominal life 3000 h – RFI suppression: feasible

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated and chromized – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 40 N – Permissible shaft loads (radial): 100 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: feasible

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated and chromized – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 180 N – Permissible shaft loads (radial): 350 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: 2 x L(3 µH)

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – DC permanent magnet motor – Graphit-copper brushes – Motor housing zinc plated – Ball bearings – Mounting holes to DIN standard 42016 General data – Nominal life 3000 h – Permissible shaft loads (axial): 30 N – Permissible shaft loads (radial): 80 N – Insulations class: DIN VDE 0530, E – Protectin class: DIN VDE 0530, IP 40 – RFI suppression: 2 x L (3,9 µH)

Request for a quote

LOSBERGER GMBH

Germany

Highlights: Permanent flexibility Lightweight Durable and Eurocode compliant Scalable for permanent flexibility The induflex is available in a large number of configurations and sizes. The structure is highly flexible and can easily be scaled up and down, allowing you to quickly respond to market developments or peaks in production or supply. So, if your requirements change, we can easily adapt your space solution within days. Safety When developing our newest structure, safety was our top priority. In recent years, the weather has become increasingly unstable and unpredictable, and safety regulations for buildings of all types, shapes and sizes have gotten stricter. Our team of engineers was able to further improve the design of the roof system, offering even more support and enabling it to carry even more weight and handle higher wind speeds than any existing common lightweight structure.

Request for a quote

FRANK EUROPE GMBH

Germany

A one-of-a-kind connecting system for premium, museum-quality showcases. FRANK showcases feature prominently in the world’s premier museums, where they protect the most prized objects history has left humankind to preserve. And with good reason: ”It’s what’s inside that counts.” This conviction of ours is reflected in a peerless, purist design that puts the object first, without neglecting function. A FRANK showcase satisfies the most discriminating expectations of great museums across the globe. The FRANK showcase system features our unrivaled slide-in technology. It requires no screws or gaskets for dustproof and airtight storage and preservation. Simply insert the inconspicuous aluminum strips into the grooves machined in the edges of the panels. No wider than the two eight-millimeter panels’ connecting joint, these slim extrusions are flush with the surface when installed.

Request for a quote

FRANK EUROPE GMBH

Germany

A one-of-a-kind connecting system for premium, museum-quality showcases. FRANK showcases feature prominently in the world’s premier museums, where they protect the most prized objects history has left humankind to preserve. And with good reason: ”It’s what’s inside that counts.” This conviction of ours is reflected in a peerless, purist design that puts the object first, without neglecting function. A FRANK showcase satisfies the most discriminating expectations of great museums across the globe. The FRANK showcase system features our unrivaled slide-in technology. It requires no screws or gaskets for dustproof and airtight storage and preservation. Simply insert the inconspicuous aluminum strips into the grooves machined in the edges of the panels. No wider than the two eight-millimeter panels’ connecting joint, these slim extrusions are flush with the surface when installed.

Request for a quoteResults for

Non-permanent - Import exportNumber of results

141 ProductsCountries

- Germany (141)

- Berlin and region (2)

- Bonn, Düsseldorf and North Rhine and Westphalia (14)

- Frankfurt am Main and Hesse (13)

- Hamburg and region (9)

- Hannover and Lower Saxony (7)

- Kiel and Schleswig-Holstein (16)

- Magdeburg and Saxony-Anhalt (5)

- Mainz and Rheinland-Pfalz (4)

- Munich, Nuremberg and Bavaria (9)

- Saarbrücken and Saarland (1)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (59)

- Weimar and Thuringia (1)

Company type

Category

- Magnets (21)

- Valves for pneumatic equipment (13)

- Disks, magnetic (11)

- Metallurgy - machinery and installations (11)

- Electric motors - dC (8)

- Office machines and equipment (8)

- Hoists and elevators, construction (7)

- Hot-air generators (4)

- Internal transport systems (4)

- Brakes, servo-brakes and accessories (3)

- Components and parts for small household appliances (2)

- Display units for exhibitions (2)

- Explosion-proof - equipment (2)

- Labels - stationery (2)

- Lifting equipment (1)

- Magnetic equipment (1)

- Sensors (1)

- Diesel engines (1)

- Display units for shops (1)

- Display windows (1)