- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing machines

Results for

Mixing machines - Import export

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDODRILL 4X GRUNDODRILL 11XP GRUNDODRILL 15XP GRUNDODRILL 15XPT GRUNDODRILL 18N GRUNDODRILL 18ACS GRUNDODRILL 28Nplus Mixing units Mixing unit MA07 Mixing unit MA09 Mixing unit MA010 Accessories Used Machines

Request for a quote

GEDA GMBH

Germany

The GEDA 300 ZP P, GEDA 500 ZP P and the 1500 ZP P have turned out to be efficient height access technology tools throughout the years. They have been transporting people and materials on asphalt producing plants, gravel plants, silos, etc. These transport platforms facilitate and accelerate regular inspections, service and maintenance. Often the producers of mixing machines use these hoist as a useful option for the ordinary stairs tower. They can also be additionally installed to already existing silos and plants without great effort and without any problems. This is possible thanks to low anchoring forces as well as to the fact that occurring vertical loads can be lead down to the basement via the mast. These transport platforms are a good-value for money alternative as you do not need a pit, a machine house and supporting constructions.

Request for a quote

GEDA GMBH

Germany

The GEDA 300 ZP P, GEDA 500 ZP P and the 1500 ZP P have turned out to be efficient height access technology tools throughout the years. They have been transporting people and materials on asphalt producing plants, gravel plants, silos, etc. These transport platforms facilitate and accelerate regular inspections, service and maintenance. Often the producers of mixing machines use these hoist as a useful option for the ordinary stairs tower. They can also be additionally installed to already existing silos and plants without great effort and without any problems. This is possible thanks to low anchoring forces as well as to the fact that occurring vertical loads can be lead down to the basement via the mast. These transport platforms are a good-value for money alternative as you do not need a pit, a machine house and supporting constructions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Duplex dosing system - optimised utilisation thanks to two scales 2 Scales in a single dosing system? A demand evaluation of dosing statistics from medium-sized perfume and aroma manufacturers as well as of similar demands from smaller sites of the top 10 F&F producers pointed to exactly that. 2 Scales because downtimes can thus be reduced to a minimum and a larger weight range can be covered. From fully automatic dosing on a small scale (up to 50 litres) to larger batches with up to 600 litres. As usual with FRICKE, the modular dosing units of the Duplex can also be flexibly expanded. OverView of performance data ■ 30 or 60 kg scale ■ 600 or 1.500 kg scale ■ Smallest pour 0,5 g ■ Batch sizes from 5 to 600 litre ■ Fully automatic container container intake ■ Flexible storage desing for raw materials ■ Fast mixing container exchange ■ Unsupervised machine operation ■ Optionally: Mixing station and powderdosing ■ Ex protection according to Atex

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix is what counts. FRIMO offers tailor-made mix and metering machines including various standardized modules for PU product manufacturing.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

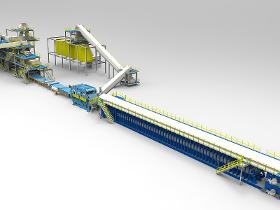

Using a ContiTherm preheater upstream of the ContiRoll® press increases the production output of a wood-processing plant signicantly. It is an additional component integrated into the forming line and serves to preheat the mat before it is transferred to the ContiRoll® infeed to just below the temperature at which the glue starts to cure. A steam-air mix is conveyed through the mat. During this process, the steam condenses at the bres or particles, heating them up. The preheating temperature can be set most accurately by varying the steam content of the mix. The machine is separate into two to four sections (seen in working direction). Depending on the application these sections are designed for a unidirectional or a bidrectional steam injection or equipped with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conveyance.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Combining additives with the virgin material at the processing machine requires excellent mixing quality and consistently accurate dosing. These requirements can be achieved and exceeded with the volumetric MINICOLOR swift V dosing and mixing unit. The units are mounted at the feed throat of the plastics processing machine and are space-saving.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

TDS Induction Mixers draw powder, liquids or gases below their level into liquids and at the same time homogenise the contents of the container. The vacuum required for induction is generated in the mixing head. The machine is installed in the container from above by means of a flange or traverse. Alternatively, the TDS Induction Mixer can work on a lifting frame. The powder is inducted from the container and introduced under the fluid level by mixing it immediately and wetting. The mixing head generates the required negative pressure. Dust loads are prevented during the addition of powder by direct induction from the bag. Effective micro and macro mixing of the complete container contents with simultaneous addition of powder. Immediate wetting under fluid level. Complete mass transfer and homogeneity across all container levels via the jetstream mixing principle. In addition, liquids and gases can be inducted.

Request for a quoteResults for

Mixing machines - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Hoists and elevators, construction (3)

- Bottling and filling - machinery and equipment (1)

- Dosing - machines and equipment (1)

- Food Processing (1)

- Mechanical engineering - custom work (1)

- Mixers and grinders for the food processing industry (1)

- Plastics - machines and material for industry (1)

- Weighing and dosing equipment (1)

- Wood veneer - machinery and equipment (1)