- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal part

Results for

Metal part - Import export

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

3D-MICROMAC AG

Germany

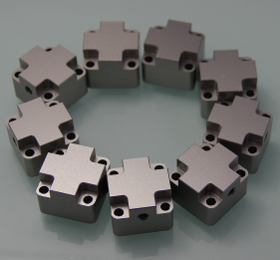

The DMP machine solutions are designed for flexible series production of complex metal components using micro laser sintering. The DMP machine series is the perfect solution to achieve superior detail resolution, highest surface quality, unrivalled accuracy, and very high part density. It offers high flexibility, low operating costs and user friendliness. The system includes a zero point clamping system for easy post-processing at the highest accuracy level and inert gas atmosphere including gas purifying based on industry standards. The DMP systems are able to process non-reactive and reactive materials, e.g. stainless steel, molybdenum, tungsten, titanium, and gold. The Micro Laser Sintering technology has been developed and is continuously improved by 3D MicroPrint GmbH. Superior detail resolution Highest surface quality Unrivalled accuracy Very high part density

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories made by aluminum, which used in many fields ,such as industrial, medical equipment and other industries.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

Parts are made to custom design from drawings, from very small quantities to industrial mass application, pursuant to standards, in a wide range. We supply components in accordance with customer requirements, with a special or knurled surface, and with a range of head forms, such as ring, eyelet, hook, triangle or ligature. Screws, bolts and axles from 1.5 mm to 12 mm can be made with lengths of up to 397 mm; customer lengths available on request (also on request with lock serrations). Knurled axles (knurling either DIN or to customer requirements), threads of M2 to M12 made of plastic or wood or with rolled thread, thick or thin shafts. Ligatures with threads of M2 to M8, or wooden thread with or without weld warts. Rivets and pins with diameters of 1.2 mm to 10 mm, with or without bevelling. Also knurled (knurling either DIN or to customer requirements).

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

We employ welding robots to join complex metal wire parts made of steel or aluminium to form an assembly. This in turn leads to complex bent wire components for the automotive industry, such as brackets for cushioning frames, and eyelet fastenings.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

With over 125 years of market experience, a network of specialised companies has evolved to serve the wide range of your customers’ requirements with the best possible quality. The focus of these long-standing cooperations is on making the most of available know-how while maintaining fair market prices. Besides bent wire and plastic components, a wide range of industries also require so-called hybrid parts. This combination of metal and plastic is found, for instance, in screw joints, connecting rods, seat elements for lumbar support, and medical engineering, among other areas. We work in close cooperation with specialised partners for plastics engineering. Our great efficiency in wire working technology and plastic injection enables us to create hybrid parts that satisfy the most stringent requirements.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

Parts are made to custom design from drawings, from very small quantities to industrial mass application, in a wide range. We work with steel, stainless steel, copper and aluminium wire and can also implement your surface requirements.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

Processes such as radial riveting or pressing are used to permanently conjoin a metal plate for example with a wire bracket. Test apparatus for monitoring compliance with the required tear values secure the process in line with these safety-relevant components. These assembly parts are used, for example, as reinforcements for backrest frames.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

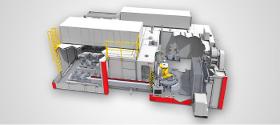

rotating spindle coating machine for larger quantities or longer process times

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle machine for coating rotationally symmetrical parts

Request for a quote

DIETZ GMBH

Germany

With laser generation, components are built up layer by layer from powdered metallic materials used in serial production such as 1.2709 steel or 1.4543 steel. Thanks to state-of-the-art technology, this enables us to transfer your computer-generated 3D/CAD models reliably over to their physical form. Here, thin coats of the powder materials are applied to a base object before being melted using a laser into the desired contour. This process is continued on a revolving basis until the workpiece is complete with the final geometric form and the relevant functional properties. Incidentally, we reclaim excess powder material during this process and use all of it for later productions again. Our services in sample development also include technical springs, which we produce in small batches for your sample application. Traditional sample development services are a new addition to our portfolio. Here, we produce a small-scale series of your bent strip parts from original materials.

Request for a quote

DIETZ GMBH

Germany

We can produce the parts you require using specific tools or on special-purpose machines. We produce complex forms and assembly parts with strip thicknesses of 0.10 to 3.00 and with strip widths of up to 100 mm – depending on the material used. The manufacturing processes that we offer include: Punching, forming, embedding, welding, bolting, riveting and mounting. We perform the assembly of small batches by hand, while larger volumes are performed automated if you so wish. Our hybrid sub-assembly production includes the over-moulding of punched parts made of wire or metal with a variety of plastics or silicones. In order to ensure that the desired braking element features optimum properties, we make use of both the temperature durability and the haptic advantages of silicone and the weight advantage of plastic when combining these materials in this fashion. Guide tube assemblies, a combination of springs and tubes, are part of the hybrid component portfolio.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

ROCHOLL GMBH

Germany

We can offer a wide range of metal test specimens, starting from different grades of steel in various thicknesses and alloys right through to non-ferrous metals. Are you looking for galvanic finishing or machining solutions? Then you have come to the right place. Punching, deburring, and the rounding of corners are an important part of our portfolio. We will be happy to finish surfaces, for example by means of degreasing or sandblasting. Further finishing options are available upon request. We can also provide test panels with a customized serial number or marking if desired. Stainless steel 1.4301, 1.4571, 1.4401, 1.4310, other grades available upon request Test specimens According to A.F.E.R.A. 4001 (old standard), with defined finish With high-gloss finish (according to FINAT, PSTC standard, A.F.E.R.A. standard 5001, EN 1939) Titanium Grade 1 and grade 5, other grades available upon request Automotive grades painted

Request for a quote

PRESSTECK S.P.A.

Germany

You don't need deep-drawn individual parts, but complex assemblies already assembled? We are your experts for that! First we analyse your requirements for new potentials. Combined with innovative thinking and agile processes, we then design smart solutions with you to manufacture your desired assemblies. Depending on your requirements, we develop decoupled, partially or fully interlinked assembly processes using high-performance systems and state-of-the-art equipment. We reliably ensure your quality requirements with integrated and individual testing measures.

Request for a quote

GSW SCHWABE AG

Germany

Safety for the workers, no damage to the coils Our practical hoists are easy to operate – for years at a time. On top of that suitable optional equipment is available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

crane forks easy to adjust to match all sizes of pallets all crane forks meet the requirements of the accident prevention regulation of the trade association quadruple safety against breaking The tines for carrying the load during the loading process tilt upwards if forks with autobalance are used. An unintentional slipout of the load can therefore be ruled out.

Request for a quote

GSW SCHWABE AG

Germany

Thrust Chain Systems and Die Trucks für safe and quick handling of dies with up to 21t weight.

Request for a quote

PRESSTECK S.P.A.

Germany

Support sleeves for reinforcing plastic components. Made of stainless steel with customised design. The bushings can be produced not only round but also oval as a deep-drawn part.

Request for a quote

GSW SCHWABE AG

Germany

This small yet complete system with reservoir, controls, valve and tubing as well as all other necessary components can be very easily installed and is quickly set to use – even for 3 mm strip thickness

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

GSW SCHWABE AG

Germany

tried and trusted a thousand times in practice the low price permits the economic use in individual shift operation and with rarely used tools can be directly mounted to each tool, no setup costs

Request for a quote

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quote

GSW SCHWABE AG

Germany

Please contact us for more information on our program of DieClamps, Roller Bars, Consoles and individual Roller Components. We will gladly furnish a quotation for your specific need for you. Our offer included hydraulic power systems as well.

Request for a quote

GSW SCHWABE AG

Germany

selfadherent blowout fitting through magnetic base amount of escaping air adjustable finely via a ball valve with position stable uniflextube for accurate positioning also suitable for cooling liquid

Request for a quote

GSW SCHWABE AG

Germany

ideal for producing an air curtain or for drying extensive areas high blowing power at significantly reduced noise development flexible in user applications

Request for a quote

GSW SCHWABE AG

Germany

high blowing power at significantly reduced consumption of compressed air and lower noise development for every case of use the right passage ideal for blowing out punch parts Heat Resistance 90° C

Request for a quote

GSW SCHWABE AG

Germany

the good value for money choice for all standard applications high blowing power at significantly lower noise development flexible in user applications low air consumption Heat Resistance 90° C

Request for a quoteResults for

Metal part - Import exportNumber of results

263 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (173)

- Machine tools, metal shaping - parts and accessories (45)

- SMALL METAL PARTS (16)

- Forming - steels and metals (12)

- Laser - cutting and welding machines (2)

- Varnishing equipment (2)

- Sheet metals - stamping (1)

- Stamping - steels and metals (1)

- Welding work - steels and metal (1)

- Engineering - industrial contractors (1)

- Magnets (1)

- Medicines (1)

- Sensors (1)

- Street-cleaning machines (1)

- Surface treatment - machinery and equipment (1)

- Vacuum cleaners, domestic (1)

- Vehicles - mechanical components and parts (1)

- Welding, soldering and brazing - equipment and supplies (1)