- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- log per

Results for

Log per - Import export

MAHLO GMBH & CO. KG

Germany

Data logging & analysis The mLog software is a data logging application for Mahlo equipment. The desktop application runs on an office PC and provides comfortable creation and archiving of PDF protocols of running measurements. The recording of the measurement data is controlled on the Mahlo device PC, the finished protocols are transferred to mLog. An advanced search function with filter categories makes finding logs easy and fast. In the protocol viewer the protocol can then be displayed, printed, saved or sent by e-mail.

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

The purchase of Aluminium alloy billet is an option available to our customers from our on-site Cast house. The billets are cast by conventional direct chill semi-continuous casting using float-dip tube technology. The subsequent homogenisation takes place in one of our two homogenising ovens. We are able to offer short lead times for machined billet in smaller quantities than would otherwise be available. With the wide range of alloys and dimensions we can offer, we will surely find a solution for you.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

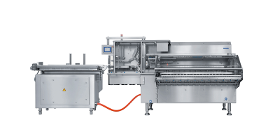

The Log Peeler CCP fully automatically and hygienically removes the casing from lunch meat and cheese products. The machine can be put together individually. A clear distinction between grey zones and hygiene zones allows the product casing to remain in the grey area, which increases the safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling. The flexible system permits simple and rapid conversion when changing calibers. Advantages Continuous production: buffering possible before and after the peeling process Casing remains in non-high risk area, increased safety for the peeled product Safe: constant control of the peeling process Optional hygiene kit Optional hygiene kit: UVC irradiation from underneath of conveyors in the product contact area UVC air disinfection within the peeling area

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Simple to use High precision Battery life > 6000 hours With calibration log

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Waterproof device and probe Battery life of approx. 6000 h Calibration log included Simple to use

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Waterproof device and probe Battery life of approx. 6000 h Calibration log included Simple to use

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Waterproof device and probe Battery life of approx. 6000 h Calibration log included Simple to use

Request for a quote

ASBER GMBH

Germany

“A single piece of wood coffee table is a part of Mother Nature's perfect creation, every texture tells a story and is a manifesto of nature's inspiration; “This table is an immortal reminder of the life of the tree.” We develop ideas and projects to present you the topic of trees, our main topic, in its simplest form. We work with universities' fine arts departments to ensure that our products come from the hands of artists. Above all, we are proud to support art students as part of a social project. The Natural/Wood/Log Coffee Table is carefully crafted from a single piece of natural solid walnut wood carefully selected from 400-500 year old trees. Therefore it should not be compared with assembled tables. No chemical substances were used in the manufacturing process and it is entirely handmade. This special table, of which only one will be produced, serves to add functionality to nature's art.

Request for a quote

ASBER GMBH

Germany

“A single piece of wooden coffee table is a part of nature's perfect creation; every texture tells a story and is a manifesto of nature's inspiration; “This table is an immortal reminder of the life of the tree.” We develop ideas and projects to present the theme of the tree, our main theme, in its simplest form. We work with university art schools and ensure that our products come from the hands of the artists. Most importantly, we are proud to support art students as part of a social project. The natural wood coffee table, Klotz Coffee Table, is carefully crafted from a single piece of natural solid walnut wood carefully selected from 400-500 year old trees. Therefore, it should not be compared with assembled tables. No chemical substances were used in the manufacturing process and it is entirely handmade. This particular table, of which only one is made, serves to add functionality to nature's art.

Request for a quote

ASBER GMBH

Germany

Our product is a handcrafted table made of solid walnut wood. The product dimensions are 260 cm long, 51-92 cm wide and 78 cm high. The design preserves the tree's natural shape and is made from a single piece of walnut trunk. Therefore every table is unique. The table legs are also made of the same wood and have a special design.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Drum chippers are used to process long and short logs, wood pieces, saw mill waste, veneer waste, residual wood, and other wood waste to high-quality chips. Depending on the size and design of the drum chipper, the machine can be adjusted to the type of wood to be processed and the desired chip quality. The most suitable chipper size is determined by the maximum trunk diameter to be processed and the desired production capacity. The desired chip length also inuences the performance of the chipper. Key features Adv Large draw-in rollers for process-reliable wood feed at constant speed Pivoting feed system for automatic adjustment to loading height Hydraulic ywheel drive for consistent contact pressure and the damping of impacts Robust, well-balanced rotor Large ywheel inertia to compensate for short-term peak loads Generously dimensioned V-belt drive Startup process via Pony-motor to reduce spikes in power supply during acceleration of the rotor

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

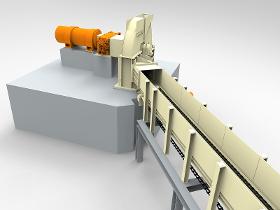

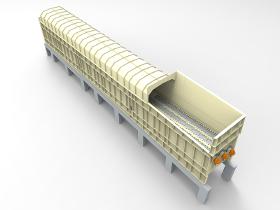

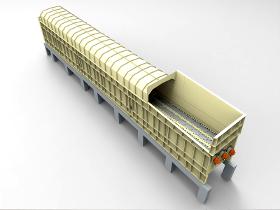

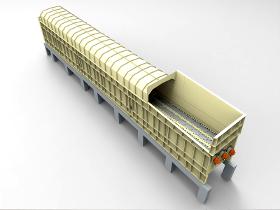

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of berboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Key features Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Options Horizontal convey for long logs Gravity feed chute for short logs

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

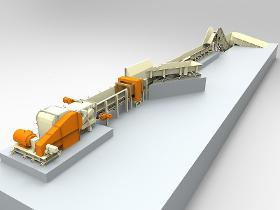

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-ecient disc and drum chippers as well as the mills for the preparation of bark, the production of highquality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Dosing step conveyor for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Depending on the debarking demand, use of drum or rotor debarker Disk or drum chipper Advantages Robust, highly controllable wood feed Debarker adapted to the debarking demand Minimal ne material content High lling level and high utilization of chipper capacity High operational safety

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the rst choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high exibility for a needs-based log feed. Key features Modular design Needs-based conguration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with dierent diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

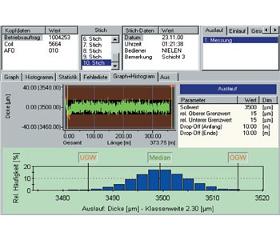

In addition to the strip speed, VRecoS also records up to three further tracks, such as the rolling force or the strip thickness at the ingoing and outgoing ends of the mill. The measurement protocols can be stored, printed out and distributed by e-mail. The measured values are recorded as a function of length. The recording frequency can be set with a scanning rate of 2 ms. Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed, even subsequently. The signals are recorded using a data collector belonging to the scope of supply. Its electronics with input and output modules is designed for installation in switch cabinets or desks in interference-proof 24 Volt top-hat (DIN) rail technology. It transmits the data via a network cable to the Windows recording computer which can be supplied by Vollmer or by the customer.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

VGraph is the software package for the recording and visualisation of data with extensive statistical data evaluation options. It synchronously records up to 16 measurement values – for example thickness, width and speed of the strip, rolling force or strip tension – on a production line, stores them and evaluates them statistically. With statistical functions such as histograms, Cp and CpK values and error lists, VGraph provides valuable decision aids for the evaluation and further use of the coil produced. The diagnostic instruments allow optimisation of the rolling process and the line engineering. The optional FFT analysis detects periodic fluctuations in the strip thickness. VGraph meets the needs of day-to-day strip production. One example: Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed – even subsequently – in the statistical evaluations.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The line for tree-length logs is designed for the processing of whole logs with lengths of up to 20 meters: With the log feed, debarker, washing system, dosing system all the way to the highly-efficient disc chippers, the production of high-quality chips is guaranteed. Features, Function Feeding of the wood from the truck or storage area Large gantry or rotating cranes for loads of up to 30 metric tons of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

We have developed the world’s largest strander: Due to the design of its knife ring with a 2,500 mm diameter, a cutting width of 850 mm, 56 knives, as well as a maximum material throughput of 45 metric tons per hour bone dry, the new OSB flaker is considered a giant. Stranders of the PZU series are able to process logs to high-quality strands with a specific length, width, and thickness. Therefore, these machines are the best choice for the production of high-quality flakes in large quantities for OSB and wafer boards. Advantages Very good ratio between loading and cutting times Improved, simpler maintenance High strand throughput High strand quality with low fines content Low energy consumption

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the first choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high flexibility for a needs-based log feed. Features, Function Modular design Needs-based configuration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with different diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the first choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high flexibility for a needs-based log feed. Features, Function Modular design Needs-based configuration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with different diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

PC evaluation software Measurement data logging Calibration / adjustment Save and load sensor parameters

Request for a quoteResults for

Log per - Import exportNumber of results

26 ProductsCountries

Company type