- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser processes

Results for

Laser processes - Import export

TEPROSA GMBH

Germany

We are specialized in performing thermal shock testing of electronic and mechanical assemblies and have a lot of experience with the requirements of the automotive industry and medical technology. On behalf of our customers, we perform environmental and climatic tests according to customer specifications and applicable standards, thus uncovering optimization potential. We will be happy to advise you with regard to your testing tasks and, together with you, transfer the entire testing process into a specification sheet. OUR OPPORTUNITIES 2-chamber system air-air Test chamber volume up to 130 liters Temperature range hot chamber 50°C to 200°C Temperature range cold chamber -80°C to -100°C Change between chambers <15 seconds Maximum test material weight 25 kg State monitoring of the test specimens during the test

Request for a quote

3D-MICROMAC AG

Germany

Besides the processing of rigid and flexible materials on rigid substrates, we also offer the processing of flexible materials using sheet-to-sheet or roll-to-roll processes: - Laser micro structuring and ablation - Laser processing “on-the-fly” or “step and repeat” - Roll width up to 300 mm possible

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Excimer Laser-Lift-Off using line-beam systems - Laser drilling and ablation using scanner systems or mask projection - Laser engraving of optical materials - Materials: polymers, polymer compounds, glass materials

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Laser cutting, dicing, and filamentation - Laser drilling – available as trepanning or percussion process - Laser micro structuring and ablation, e.g. with FSLA technology - Laser micro engraving, both on the substrate surface and as sub surface engraving in transparent materials Laser-Lift-Off (LLO) using DPSS laser and scanner systems Materials: ceramics, metals, polymers, glass materials, semiconductors, compound material

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – s200RW is a heat treatable product for applications with extremely demanding formability requirements. Fusion™ 6HF – s200RW offers the ultimate additional solution for remote laser welding of aluminium 6xxx alloys without the need for any additional metal. Access to the weld area is enhanced, welding speed is increased and the stability of the process is improved in comparison with standard laser welding processes. This product is recommended for inner panels with high formability requirements such as door inners or other closure inner panels. With Fusion™ 6HF – s200RW “near-edge” welding, a reduction in the flange length to as little as 5mm becomes possible. All values are typical.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

FÖHRENBACH GMBH

Germany

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

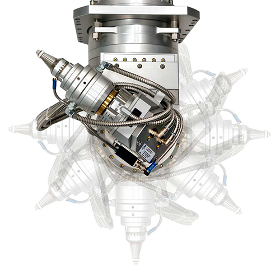

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Improve process control with wide choice of spectral ranges and focus distances designed specifically for your application Reduce setup time with plug-and-play technology and integrated laser sighting Protect your process and employees with intrinsically safe ATEX/IECEx/CCC-IS certification Choose from options of analogue and digital communication protocols Designed for harsh environments, Thermalert 4.0 Series Pyrometers provide accurate, real-time temperature measurements for process control applications spanning metals, plastics, glass, oil and gas, food and more. This robust solution comes in a compact, integrated package that is easy to install and operate, so you can take your process control to the next level.The Thermalert 4.0 Series Pyrometers from Fluke Process Instruments include numerous integrated infrared temperature sensors with our widest selection of spectral ranges that can be used for a wide variety of process control applications.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

TEPROSA GMBH

Germany

We offer laser direct structuring (LPKF-LDS process) for the production of 3D-MID (so-called three-dimensional circuit carriers) as a service in Magdeburg. 3D-MID stands for Mechatronic Integrated Device (or Molded Interconnected Devices). The MID technology makes it possible to use three-dimensional plastic parts as circuit carriers for electronic or mechatronic assemblies. The LPKF-LDS process is one of the technologically leading and at the same time most economically interesting process for the production of 3D-MID. The LPKF LDS process represents the central process step. The process was developed and patented by the company LPKF Laser & Electronics AG in Hanover.

Request for a quote

TEPROSA GMBH

Germany

We offer our customers laser cutting of fine and thin sheets, as well as laser fine cutting of materials with very low material thicknesses (0.02 mm – 4.00 mm) as contract manufacturing. Of course we manufacture from the first sample and also up to mass production. If you do not know whether your material is suitable for processing with the laser, we will be happy to find out for you and provide you with a first demonstration sample free of charge.

Request for a quote

SPIROL

Germany

SPIROL specializes in the custom manufacturing of tightly toleranced Precision Shims, Specialty Washers and Thin Spacers. SPIROL produces Shims custom-made to customer specifications in thicknesses ranging from 0.02mm up to 9.5mm (.001" up to .375") using a variety of stamping methods, machining processes and laser technology to meet your specific lead time and total cost considerations. Whether a project is for prototype, short run or long-term requirements, SPIROL has a solution to minimize costs by controlling - or even eliminating - tooling costs. In addition to having flexibility in our primary operations, SPIROL also performs most secondary processes in-house including heat treating, grinding, lapping, high speed polishing deburring, finishing and passivation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROLASER GMBH

Germany

The laser system size XL-1600 is the professional solution for the laser processing of textiles. Besides, the automatic conveyor system enables the possibility to process textiles directly from the roll. By doing previous cutting tests with your individual materials, we test which laser system configuration would be the most suitable for you in order to achieve optimum results.

Request for a quote

EUROLASER GMBH

Germany

With the laser cutting and engraving machine XL-1200 eurolaser offers the possibility to process extremely broad materials on a comparatively small system. The processing area is 2,270 mm x 1,230 mm (89.3" x 48.4"). With the optional camera recognition system which is also available for other systems the production flow can be automated, leading to an increased economy of the laser processing. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with

Request for a quote

EUROLASER GMBH

Germany

Various materials can be cut and engraved on a processing area of 1,800 x 3,200 mm (70.8" x 126"). This CO2 laser machine is one of the largest among the eurolaser series and is available with many optional features. An ideal machine size for all applications requiring plenty of space. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

EUROLASER GMBH

Germany

Das Laser Cutter- und Gravur-System L-1200 bietet einzigartige Präzision und Schnittqualität bei höchsten Schnittgeschwindigkeiten, die sich je nach zu bearbeitenden Material durch individuelle Laserleistungen anpassen lassen. Alle eurolaser Cutter-Systeme sind mit Laserleistungen von 60-650 Watt erhältlich. Für Sie bedeutet das anwendungsbezogene Effizienz. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

EUROLASER GMBH

Germany

The eurolaser laser cutting machine M-1200 is a compact model with a processing area of 1,330 x 1,230 mm (52.3" x 48.4"). Just like all eurolaser laser cutting machines the sealed-off laser technology in connection with exchangeable modular assembly groups reduces the lifecycle costs to a minimum. An investment which pays off! The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

EUROLASER GMBH

Germany

The laser cutter M-800 with a processing area of 1330 x 830 mm (52.3" x 32.6") is well-prepared for all applications in the fields of laser cutting, engraving and marking. A special feature is the optional shuttle table system, which almost doubles your productivity, enabling you to hold all the aces even with a “smaller“ laser cutter. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

EUROLASER GMBH

Germany

The laser cutter size XL-1600 is the professional solution for the laser processing of wood. With its modular concept and the easy handling it offers a future-oriented and efficient investment – just like all other laser cutting systems. With cutting and engraving tests performed on your individual materials we determine in advance the optimal configuration of your laser cutter.

Request for a quote

EUROLASER GMBH

Germany

With the laser cutting and engraving machine XL-1200 eurolaser offers the possibility to process extremely broad materials on a comparatively small system. The processing area is 2.270 x 1.230 mm (48,4 "x 89,3"). With the optional camera recognition system which is also available for other systems the production flow can be automated, leading to an increased economy of the laser processing.

Request for a quote

EUROLASER GMBH

Germany

The laser cutter size XL-1600 is the professional solution for the laser processing of acrylic glass. With its modular concept and the easy handling it offers a future-oriented and efficient investment – just like all other laser cutting systems. With cutting and engraving tests performed on your individual materials we determine in advance the optimal configuration of your laser cutter.

Request for a quote

EUROLASER GMBH

Germany

With the laser cutting and engraving machine XL-1200 for acrylics eurolaser offers the possibility to process extremely broad materials on a comparatively small system. The processing area is 2,270 mm x 1,230 mm (89.3" x 48.4"). With the optional camera recognition system which is also available for other systems the production flow can be automated, leading to an increased economy of the laser processing. The requirement-focused modular design enables eurolaser laser systems to be specially configured to suit every requirement and at the same time provides the necessary flexibility. The system design is focused mainly on requirements that are generated from later use.

Request for a quote

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quoteResults for

Laser processes - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (30)

- Laser apparatus and instruments (7)

- Steels and metals - welding and brazing (2)

- Construction - Machines & Equipment (2)

- Import-export - electrical and electronic equipment (2)

- Pad printing (2)

- Cars - electrical and electronic parts and components (1)

- Cutting - machine tools (1)

- Engineering - industrial contractors (1)

- Foundry machines - centrifugal (1)

- Infrared tubes (1)

- Screw cutting - steels and metals (1)

- Steel & Metals (1)

- Vehicles - mechanical components and parts (1)