- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ingot

Results for

Ingot - Import export

QUELLTECH GMBH

Germany

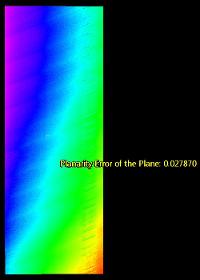

QuellTech Solution: The performance of a manual inspection cannot be compared with the speed and the repeatability of a contactless QuellTech Q4-1000 laser scanner. It is even possible to install several instruments in parallel to cover the whole width of the ingot with one single scan. These instruments are mounted on an existing portal and correctly synchronized, so that interaction of the laser light originating from the other scanners is excluded. The QuellTech laser line scanners produce 3D point cloud of the raw ingot surface, and the software calculates the coordinates of the highest and deepest levels of this surface. After scalping the flat surface can be scanned again for any defects. Benefits for the Client: Thanks to QuellTech’s wide area laser line scanners, the cycle times for ingot scalping could considerably be reduced, and excessive material scrap due to a too low scalping level is prevented.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

To produce industrial aluminum of this caliber, Novelis begins by carefully controlling the composition of the alloy, then taking exceptional care in the casting procedure to avoid non-metallic impurities. The surfaces of the aluminum ingots are then sawed and scalped to remove any new impurities before rolling. These ingots are preheated for long periods for optimal homogenization of the metal structure, then hot- and cold-rolling procedures achieve high surface quality. “Bright rolling” delivers the highest possible surface consistency and reflectivity. The result is an aluminum surface reflective enough to be used as a mirror.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic plate saw VPS60-160A is BEHRINGER's solution when it comes to fully automatic cross-cutting of large plates and blocks. The vertical arrangement of the saw band has clear advantages over the horizontal design, as the engagement length of the saw band is significantly shorter. As a result, the cross cutting plate saw offers significantly higher cutting capacities while at the same time reducing tool costs. Thanks to their robust basic design and high-performance components, the automatic plate saws of the VPS series are designed for demanding applications in the steel trade, industry and metal production. From non-ferrous metals and aluminum to simple work steels and difficult-to-cut materials such as Inconel or titanium. Their modular design allows the cross cutting plate saw to be individually adapted to the customer's application.

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

SiBrickScan (SBS) is a dedicated at-line system for the FTIR quantification of interstitial Oxygen in complete Silicon ingots, resulting in a concentration profile along the longitudinal axis. Accessing this information without sawing wafers or test samples is a major and cost saving advantage. Get Valuable Information to Check and Optimize Product Quality Knowing the Oxygen gradient of Si ingots enables important conclusions helping e.g. to control and optimize the Silicon crystallization process or to identify batches of bad raw material. Therefore SBS will help to save costs by optimizing product quality and reducing the amount of defective wafers. The random sampling of individual ingots does strongly reduce sample preparation efforts and provides relevant information much earlier.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ZINC INGOT Usage: Mainly used for die-casting alloy battery industry Pharmaceutical / rubber industry Chemical industries zinc and other metal alloy plating coating industry in applied widely. Factory with strong supply ability silver white lustrous metal zinc ingot for die-casting alloy battery industry 1. mainly used for melting ingot 2. discontinuous melting with scrap 3. Used for industry such as automobile,pinning and weaving,electron broadly and so on

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ZAMAK INGOT Zamak alloys were developed for the first time in the United States in 1929. The word Zamak comes from the German acronym and represents the elements it is made of: Z for Zink, zinc, A for Aluminum, aluminum, MA for Magnesium, magnesium, and K for Kupfer, copper. At its very beginning, Zamak was used just for decorative applications; later, the strength of this material determined its success in many other productions.

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== LEAD INGOTS Often lead ingots are purchased by enthusiasts who wish to cast their own items, such as lead bullets and lead fishing sinkers and other lead ballast applications. Care should be taken when casting with lead. Melting lead and casting lead objects can expose you and others in the area to lead, which is known to be a health hazard. Protect yourself by using all available safety equipment. The fumes coming off the melting lead can be a significant health issue; therefore you should never melt lead without strong ventilation. Lead ingots can be manufactured to required purity levels or as alloys of Antimony and Tin with defined properties. This can be specified so that the lead ingots meet the application requirements.

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== MAGNESIUM INGOT The proportion of magnesium alloy is the lightest among all structural alloys, so the weight of aluminum or iron can be reduced without reducing the strength of the parts. Smelting from minerals into metals is mostly made up of raw embryos of various sizes and shapes. Magnesium Alloy Casting Ingots can be used to make all kinds of plates, wires and profiles, as well as for use in chemical industrial, military industrial and meter instrument manufacture, etc. In the elastic range, the magnesium alloy by the impact load, the absorption of energy than aluminum alloy, so the magnesium alloy has a good seismic noise reduction performance.

Request for a quoteResults for

Ingot - Import exportNumber of results

10 ProductsCountries

Company type