- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial furnaces

Results for

Industrial furnaces - Import export

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Steel Industry / Industrial Combustion Technology / Industrial Furnaces

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Renewable Energy Technology / Environmental Technology / Industrial Furnaces One-piece body, centric disc Operating temperatures up to 620°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Renewable Energy Technology / Environmental Technology / Industrial Furnaces One-piece body, centric disc Operating temperatures up to 800°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Furnaces / Steel Industry / Industrial Combustion Technology One-piece body, centric disc Operating temperatures up to 550°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length acc. to DIN EN 558-1 R20, from DN400 acc. to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266 SIL certification according IEC 61508 and IEC 61511

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: Hochtemperaturbeständig High-temperature-resistant and strong silicone adhesive and sealant. Especially suited for heat-loaded, elastic adhesive bonding and sealing. Very good adhesion on steel, aluminium, glass, ceramic and many other materials. Applications: Industrial furnaces, Flue gas boxes, Heating facilities, Exhaust pipes and Heating cabinets and furnaces. The outstanding product properties (e.g. permanent elasticity) are maintained in the entire temperature range from -60°C to +300°C. Properties: High temperature resistance up to +300°C, Very good UV stability, Excellent resistance to weathering and aging, Good chemical resistance, Elongation to break approx. 500% and Colour: red.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

—Capacitive proximity switches for the detection of non-metallic and metallic objects —for use at temperatures from -40°C…+200°C —With stainless steel thread and PTFE tip —for counting, position queries of parts or products, for example in furnace technology, chemical industry or plastics processing"

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

—Capacitive proximity switches for the detection of non-metallic and metallic objects —Smooth plastic sleeve —Diameter 20 mm, 34 mm —for counting, position queries of parts or products, for example in furnace technology, chemical industry or plastics processing — with additional PTFE sleeve suitable for level monitoring in tanks

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

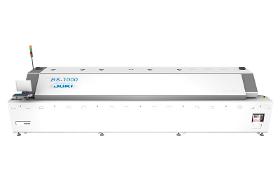

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 600 6 zone reflow soldering oven is the space saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Can be mounted on the pressure or suction side of a pump Space-saving installation, because no straight inlet/outlet sections are required Flexible mounting of the meter in horizontal, vertical or inclined positions Accurate measurement result, since the reading is independent of the temperature and viscosity of the fluid Minimum failure costs due to simple function monitoring, rapid fault analysis and the possibility of simple repairs on site Areas of application To measure heating fuel consumption by oil burners (for example, in heating boilers, industrial furnaces, tar processing plants) Consumption monitoring and optimisation (ships, generators and vehicles) Flow measurement for mineral oils Optional remote processing and integration into superior systems Fuel types Fluids according to ISO 8217-2012 Heating fuel extra light/light

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Mass flow measurement Integrated temperature sensor Simple burner setting with flow rate display Simple consumption monitoring with limiting value switch Qmin/Qmax Manual dosing feature, with a resettable counter be mounted on the pressure or suction side of a pump Space-saving installation, because no straight inlet/outlet sections are required Flexible mounting of the meter in horizontal, vertical or inclined positions Accurate measurement result, since the reading is independent of the temperature and viscosity of the fluid Minimum failure costs due to simple function monitoring, rapid fault analysis and the possibility of simple repairs on site Areas of application To measure heating fuel consumption by oil burners (for example, in heating boilers, industrial furnaces, tar processing plants) Consumption monitoring and optimisation (ships, generators and large vehicles, etc.) Flow measurement for mineral oils Optional remote processing and integration into...

Request for a quote

IBK WIESEHAHN GMBH

Germany

Fabric compensators are highly flexible and usually made of multi-ply fabric, offering excellent temperature resistance and chemical resistance depending on the particular design. Mainly used in pipe and conduit systems to compensate for axial, lateral and angular movements. One major advantage of this type of compensator is the low restoring forces. Special fabric materials permit temperatures of up to 1,000°C. Additional insulation can be used to resist temperatures of up to 1,600°C . Applications: Chemical plants, refineries, metallurgical industry, ventilation systems, chimney construction, industrial furnace construction, power stations, boiler systems, waste incineration plants, acoustic decoupling. Materials: Kevlar, fibre glass, glass needle felt, stone mineral wool mats, ceramic fabric, ceramic fibre mats, silicate felt mats, silicate fabric, Teflon Connection types: Continuous screws and screwed counter flange, clamping bars, tensioning belts straps

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

The pressure transmitter is particularly suitable for measuring volume flow of town gas supplies or other gaseous hydrocarbons such as butane, methane etc. in industrial furnaces or combustion plants. The instrument does not generate any ATEX zone as its design and technical safeguards mean it poses no ignition hazard. The measuring range is scalable in the range from 10 .. 100 %. This can be performed using a keyboard and display (optional). The measured values can be displayed in all standard units. A selectable time constant allows the transducer to be adjusted perfectly to the pressure conditions and thus ensures a stable output signal. The P 29 can be mounted either on a wall or on top-hat rails.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Industrial furnaces - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Metallurgy and iron and steel industry - machinery and installations (4)

- Ovens, kilns, furnaces and hearths, industrial (3)

- Heat treatment furnaces (2)

- Sensors (2)

- Industrial furnaces (1)

- Chemicals - Basic Products & Derivatives (1)

- Compensators (1)

- Offshore construction (1)

- Precision measuring instruments (1)

- Steel & Metals (1)