- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating jackets

Results for

Heating jackets - Import export

FRIEDR. FREEK GMBH

Germany

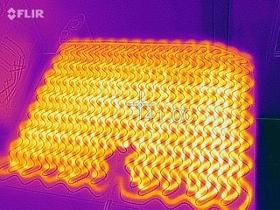

The HISDpro - Side Drum Heater is a simple yet effective silicone insulated drum heater for the heating of barrels up to 90°C. The Silicone heating jacket is available in four standard sizes (25 / 50 / 105 / 200 liters) and can be manufactured to customer specifications as well. HISDpro heater jackets are particularly suited to melt soaps, fats, varnishes and oil-based products, or respectively reduce their viscosity. The 200-liter element can be combined with the HBD - base drum heater to reduce the heat-up time. These heater jackets are not only used on drums but also containers and any kind of glass-fibre reinforced plastics. They can be produced with any number of belts, e.g. to enable them to be clamped on to rotor blades.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The IBC/Bpro-Container Jacket Heater is an insulated heater jacket for the heating of bottle-in-a-cage containers. All four sides of the container are covered by the heater. The container heater has two separate heating circuits (top and bottom), allowing for an economical heating of half-filled containers, too. The HILC unheated insulated lid can be used in addition to shorten the heat-up time. The IBC/B heating jacket can also be combined with the IBC/A container base heater. It's a silicone heater mat that is placed below the plastic container before that is filled.

Request for a quote

FRIEDR. FREEK GMBH

Germany

We offer an extensive range of drum and barrel heaters and container heaters: Heating jackets, silicone drum heaters, base drum heaters and insulating but unheated drum jackets and lids for heating and insulating plastic and metal drums respectively containers. According to the destined application we use polyester, silicone, teflon and glass fibre for our drum heaters and container heaters. Some of the materials are coated and multi-layered resp. combined. Our drum heaters can be used individually and in combination and can be ordered and delivered online (shop.freek.de) for all standard drum sizes (25 / 50 / 105 / 200 litres). Of course, we also manufacture our heating jackets, heating sleeves, base heaters and insulating bonnets individually to fit your container and your special application. HC - Heating cabinets If you heat several drums or containers together or need a container heater for the ATEX area, the heating cabinets from our partner Amarc are the right choice.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HSHP – Drum Heater (220 °C) is suitable for steel drums (and with restrictions also for plastic drums). The outer material is a Teflon which is released for contact with food. The material possesses high levels of chemical and acid resistance. However, products such as waxes, soaps and materials with high water content can be heated excellently as well. The drum heating jacket is lightweight, robust and free of silicone. The excellent thermal transfer properties due to the perfect fit result in homogenous temperatures. Our silicone-free high-temperature drum heater is available in the standard size of 200 liters but can also be made to customer specification.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HTSD-High Temperature Drum Heater is our high temperature drum heater (220 °C) and exclusively suitable for steel drums. The heating jacket is used in areas where large surfaces need heating over 90 °C. This barrel heater is available in four standard sizes (25 / 50 / 105 / 200 liters) and can be manufactured to customer specifications as well. HISD heater jackets are particularly suited to melt soaps, fats, varnishes and oil-based products, or respectively reduce their viscosity. The 200-liter element can be combined with the HBD - base drum heater to reduce the heat-up time. The heating element of the HTSD heating jackets is sewn into a fleece made of silicone-insulated fibreglass material. The insulating outer housing consists of a binder-free mat made of textile glass. The heating element is therefore double insulated (protection class II). An optimal contact with the barrel, as well as a quick assembly and dismantling are achieved by the use of quick release buckles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNIEWINDT GMBH & CO. KG

Germany

High performance cartridges and heating elements are excellently suited to direct heating of all kinds of tools. Area, ring and barrel heaters are suitable for heating boilers and moulds, tools, die plates, machine parts and a range of other purposes. They can be manufactured individually to size, voltage and output specifically for your application. High performance cartridges are suitable for tool heating in the many different fields in which a specific compatible operating temperature is required. High performance cartridges are essential in the thermal machining process field. High surface loadings facilitate a correspondingly high performance in a small installation area, at operating temperatures of up to 750°C at the heating cartridge jacket. We produce diameters between 6 mm and 45 mm to order. Different types of feed also allow high performance cartridges to be matched to the relevant installation situation.

Request for a quote

EMBRO GMBH

Germany

Embro is a German manufacturer of textile-based heating elements and pads. The elements are highly flexible, lightweight, and they are ideal for all kinds of mobile heating solutions such as: > car seat heaters > steering wheel heaters > heating elements for garments (jackets, gloves, ...) Furthermore, our elements are often used in infrared heating panels, too. Do not hesitate to contact us for further information.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

SF cabinets are used to quickly qualify a coating or material on a pass-fail basis, or determine the probability of corrosion of a specific material. SF applications include: Architectural, Chrome Plating, Fastners, Government, Military, Paints/Coatings, Laminated/Coated Plastics and Steel Structur Durable steel cabinet with 55 gallon (208 l) solution reservoir with mixing system on stand Cabinet heated by water jacket on four sides and bottom Exposure zone lined with corrosion-resistant PVC sheets Clear cover allows viewing of test conditions Peaked cover prevents dripping of condensation onto samples Water seal Heated humidifying tower with air relief valve Automatic DI water fill to humidifying tower Automatic solution level control Digital temperature control and readouts Certified air pressure gauge accurate to 1 psi (6.9 kPa) Integral over-protection on all heaters Low water cut-off protection on humidifying tower Two digital temperature controllers Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) SF260 - 420L, 0.76 x 0.56 x 0.99 m, 1.07 x 0.97 x 1.52 m SF500 - 555L, 0.76 x 0.74 x 0.99 m, 1.22 x 1.07 x 1.52 m SF850 - 860L, 1.14 x 0.76 x 0.99 m, 1.57 x 1.07 x 1.52 m SF2000 - 1930L, 1.83 x 1.07 x 0.99 m, 2.44 x 1.37 x 21.60 m SF3600 - 2850L, 2.36 x 1.22 x 0.99 m, 3 x 1.52 x 1.60 m SF4200 - 3680L, 3.05 x 1.22 x 0.99 m, 3.81 x 1.52 x 1.60 m Recorder, 2-pen circular chart, wet bulb and dry bulb UL approval Shut-down timer SF combination exhaust condenser and wet bottom drain SF exhaust recirculation system Precision air regulator, accurate to 0.01 psi (0.069 kPa) External collection package. Horizontal dispersion system High temperature package Chromasoft software High voltage kit (over 480 VAC) High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports)

BUSS-SMS-CANZLER GMBH

Germany

Short path distillation is a thermal separation technology operating at process pressures in the range of 1 to 0,001 mbar. It lowers the boiling temperature and is an excellent method for gentle thermal treatment of heat sensitive, high boiling products. The short path evaporator consist basically of a cylindrical body with a heating jacket, a rotor and an internal condenser. The rotor creates a mechanically agitated, thin product film on the heating surface inside of the body. By means of gravity the product flows down in a spiral path, whereby the volatile portion of the product evaporates. The vapour passes by the shortest route and with practically no pressure drop to the internal condenser. The non-volatile portion reaches the lower part of the evaporator and is discharged through the bottom product outlet. The residual vapours and inert gases flow through the vacuum nozzle to the vacuum system.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

The vertical thin film dryer consists of a cylindrical, vertically arranged body with heating jacket and a rotor inside. The rotor is equipped with rows of pendulum blades all over the length of the dryer. The hinged blades spread the wet feed product in a thin product layer over the heated wall and mix the product layer material intensively. Therefore the volatile components evaporate continuously from the product layer with high evaporation rates. The hinged blades are designed with a minimum gap to prevent fouling of the heating surface by product, but are never in contact with the heated wall. The product enters the dryer at its top. The evaporation starts after heating to the boiling point. In the slurry zone first solids are formed and with advancing evaporation of the volatiles and continued shearing by the hinged blades the paste breaks up to powder. The final solid product is discharged by gravity at the bottom of the dryer via a suitable air lock.

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,CIP Unit •,Storage tanks •,IP56 Control panel •,Piston Homogenizer •,Double jacket mixer Preparation unit •,Pasteurizer machine •,Butter molds melting tank •,Pasteurization Holding tubes •,Swing bend panel •,Lobe pumps PL150 •,End product storage tank with double jacket “ heat and cooling system •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series CCD (100 - 20,000 liters) The Cylindro Conical Dryer CCD with a central shaft agitator was developed to be used both as a dryer (e.g. for filter cake) and also an evaporator when products have to pass a critical phase change from fully liquid to final bulk solid. The robust mixing element is showing its effective performance also during liquid and high viscous pasty phase to finally achieve the desired solid phase. As a dryer it is designed with a vacuum-/pressure rated vessel, heating jacket and integrated dust filter. Like for the CCM (Cylindro Conical Mixer) also the CCD offers a big advantage with a compact and space saving design. Special properties for the customer’s benefit: Short drying times because all product of the batch is permanently in motion thanks to a heated helix agitator (optional) Uniform heat distribution during the process without cold spots Variable speed of the helix agitator for optimum product quality Useful working volume from 15% to 80% of the...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series DF 050 - DF 600 Mixing, stirring, cooking and sterilising are basic operations in food production and processing. The BOLZ-SUMMIX cookers with their conical construction and rotating mixing screw, have proven particularly useful for processing natural products such as coffee beans, cocoa nibs, gluten or nuts such as chestnuts. Various processes can be realised such as a heat treatment process by direct steam injection and heated jacket with continuous mixing, injection/absorption of process liquid, cooking and sterilising as well as extraction of components. Special properties for the customer’s benefit: Short process time with gentle and effective product mixing and intensive heat transfer Injection of steam via a ring channel Vacuum and pressure rated equipment Total drain of solid and liquid in a short time Flexible hence suited for a wide range of products, process and heat treatment Quick adding of required process liquids

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 300 - 500 TC The HEINKEL Pilot Plant Vertical centrifuges are characterized by a mobile compact design and easy installation for use in the laboratory and pilot plant. The centrifuge is specially designed for cGMP requirements in the chemical industry. Special properties for the benefit of the customer: Mobile, compact design Very simple installation “plug and use” application Ideal for “upscaling” Jacketed to heat up and cool down Baskets for basic tests for filtration, sedimentation and classifying

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The sample to be distilled is exposed only for a very short time to the heating substances because the film, created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. The evaporated product (operation pressures down to 103 mbar and temperatures up to about 300°C) has to pass a “short path” to the condenser only, which is located in the middle of the evaporator. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Evaporators in stainless steel can be heated by a heating jacket to higher temperatures with more heat transfer area for higher throughputs.

Request for a quoteResults for

Heating jackets - Import exportNumber of results

16 ProductsCountries

Company type