- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas heater

Results for

Gas heater - Import export

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Electrical gas heaters for operating pressure up to 500 bar - Seal gas heaters, fuel gas heaters - Natural gas heaters for gas pressure regulation stations - LNG and LPG vaporizers - Vaporizers and heaters for industrial gases - Process heaters - Gas heaters for analysis and laboratory application ATEX, IECEx, TR-CU and other international certificates

Request for a quote

FRIEDR. FREEK GMBH

Germany

Freek pump and gas line heaters for trace heating are designed to regulate temperatures in order to prevent freezing or condensation in the line. As with all our heaters, these can be designed and produced to your bespoke specifications. A most frequent application for gas & pump line heaters the semi-conductor process in which gases such as Tetraethyl Orthosilicate (TEOS), Boron Trichloride (BCl3), Aluminium Chloride (AlCl3), Chlorine Triuoride (ClF3) and Dichlorosilane (DCS) condense at low temperatures. Should this occur, it could result in wafer defect. Gas and pump line heaters consistently heat the lines and provide a simple heating solution and prevent condensation build up. The optimum line temperature will vary depending on the process.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Preformed silicone heaters are useful for diamters as small as 12 mm and up to 100 mm. Rounded silicone heaters are not possible with self-adhesive foil. Spiral Wrap Pre-Formed Silicone Rubber Heaters are suitable for tubes and flexible pipes and hoses with Ø 6,35 mm (1/4"). Spiral formed flex heaters can be used up to Ø 12 mm (the length of the stretchable silicone spiral wrap heater is reduced accordingly). The thickness of our spiral-wrapped silicone strip heaters is 2,2 mm. Also our gas and pump line heaters, most frequently used in the semi-conductor process, are shaped and pre-formed according to the object geometry to be heated. They are designed to regulate temperatures in order to prevent condensation in the line. Current applications here are Semi Conductors, Vacuum Chambers, Wafer Chucks, Valves, Exhaust & Pump Systems.

Request for a quote

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Immersion heaters from 0,1 kW up to 300 kW for tank heating or as components for machines: - Lube oil heaters for compressors, pumps, turbomachinery, refrigeration machines and others - Tank heaters for oil, water and other liquids - Gas heaters for process applications - Anticondensation heaters for electrical motors and machine housings Range from 0,1 kW up to 300 kW ATEX, IECEx, TR-CU and other international certificates

Request for a quote

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Electrical pocess heaters from 0,5 kW up to 1000 kW including pressure vessel, according ASME, PED or TR-CU. Gas heaters for natural gas, seal gas, fuel gas, industrial gas applications, process gas. Liquid heaters for oil, water and any process liquids. ATEX, IECEx, TR-CU certificates. Operating temperature up to 1000°C Operating pressure up to 500 bar

Request for a quote

FRIEDR. FREEK GMBH

Germany

Screw-in Tubular Heaters are the standard solution for all heating processes with liquids or gas. The heater is installed in a tank or a tube system by the G1½" screw fitting. The IP54 connection head, fitting and tubular heater consists of stainless steel. The tube sheath material 1.4529 is resistant to sulphite, phosphors and hydrochloride media.

Request for a quote

APROVIS

Germany

* FriCon - gas dehumidification * Gas heaters * ActiCo - activated carbon filters * Gas compressors * Process gas heat exchangers

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Flameproof unit air heater ATEX EEx d IIC T3 ATEX The „FUH“ range of flameproof electrical unit air heaters offer a hazardous area, space heating solution, for large premises requiring high heating capacity. They are certified for zone 1 or 2 areas, where the flammable atmosphere is a group IIA, IIB or IIC gas. This heater has an internal fan.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Flameproof mini line heaters ATEX Ex II 2 G Ex’d’ IIC T4-T6 nach EN60079-0 und EN60079-1 The Exheat range of flameproof mini line heaters consist of a screw plug or flanged type immersion heater mounted in a thermally insulated heating vessel. They are designed to efficiently transfer heat to a flowing medium (liquid, air or gas). All flameproof heaters are fully ATEX certified and designed for use in zone 1 & 2 hazardous areas, gas group IIC.

Request for a quote

TROTEC GMBH

Germany

Wherever condensation free warmth is needed without long air transportation ways, on site and immidately effective, the favourable electric heating units of the TDS R series are best choice. Because in comparision to direct fired gas or oil heaters dont consume oxygen and produce no combustion gases, they are well suited for temperature management of unheated inside rooms, workshops or garages. Thanks to the integrated thermostat control the produced warm air flow can be adjusted continuously to the desired temperature. If needed, the heating elements of the TDS 30 R switch on thermostatic controlled additional to the constant fan. Benefits in practise: Multistage temperature control with up to 3 heating stages Integrated room thermostat for constant, cosy warmth Overheat protection Fan motor with thermal protection Condensation-free heating - no oxygen consumption - because of that the TDS 30 R is suitable for uses in enclosed rooms Easy transportable and easy to use

Request for a quote

TROTEC GMBH

Germany

TDS 50 Electric Fan Heater The TDS 50 electric heater provides a heating performance between 4.5 kW and 9 kW in 3 stages (stage 1 only fan). Furthermore the TDS 50 has an integrated thermostat for continously adjusting the desired temperature. In comparison to direct fired gas or oil heaters, the electric fan heaters of the TDS series dont consume oxygen or produce combustion gases. Because of that this devices can be used everywhere, in particular for temperature control of unheated interiors. Benefits in pratice: 100% TROTEC - development, design, production Multistage temperature control Integrated room thermostat for constant, cosy warmth Overheat protection Fan motor with thermal protection Condensation-free heating - no oxygen consumption - because of that the TDS 50 is suitable for uses in enclosed rooms Wall and ceiling bracket available - mounting is available as an accessory

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

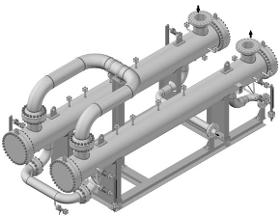

CHARACTERISTICS optimum thermal efficiency optimum efficiency of the turbine optimum load-case design flow optimized design vibration-optimized design OPTIONS custom specific design on international design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) design acc. to TEMA custom specific TPIs (Inspections / Third Party Inspections) custom specific testings sour gas application (NACE) temperature range -50 °C till + 350°C custom specific nozzle orientation GENERAL Performance Heaters, type VEV-LS are serially arranged heat exchangers, which heat up gas for a subsequent system requirement. Performance heaters can also be designed as coolers in reverse. The design is carried out as a steel welded construction in a horizontal design. FUNCTION Fuel Gas Performance Heater Type VEV-LS are used in high efficient combined-cycle gas and steam power plants (CCPP).

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quoteResults for

Gas heater - Import exportNumber of results

25 ProductsCountries

Company type