- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- friction-resistant

Results for

Friction-resistant - Import export

ROLLON GMBH

Germany

The PLUS SYSTEM series of linear actuators consists of highly protected linear units featuring a self-sustaining anodized aluminum structure and a steel re-enforced driving belt. This is a line of exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration. High load capacity,High speed,Low wear and tear,Low friction,Low maintenance.Corrosion resistant version All Plus System series of linear actuators are available with stainless steel elements, for applications in harsh environments and/or subject to frequent washes. The Plus System linear units are made by using extruded anodized Anricorodal 6060 and 6082 aluminum, which houses bearings, linear rails, nuts and bolts and components made of low carbon SS AISI 303 and 404C steel, preventing or delaying corrosion caused by humidity experienced in the environments where the linear units are used.The PLUS SYSTEM series consists of 3 distinct products with different features: ELM,Robot,SC.

Request for a quote

IGUS® GMBH

Germany

iglidur® H1: The endurance runner for high temperatures iglidur® H1 is the first choice when high holding times are required in extreme environmental conditions. Extreme wear resistance is coupled with excellent resistance to temperature and chemicals - not only in the packaging and foodstuff industries or the automotive industry. iglidur® H1 is available as cylindrical bearings and plain bearings with flange. High wear resistance in extreme ambient conditions Very low coefficients of friction High resistance to temperature and chemicals For applications in the engine compartment

Request for a quote

IGUS® GMBH

Germany

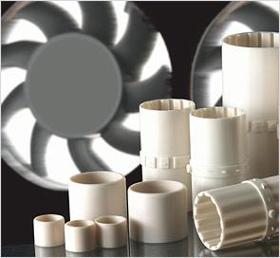

iglidur® L250: For fast rotations Bearings for fast rotary motions like, for instance, in fans and small motors. iglidur® L250 is available as cylindrical bearings and plain bearings with flange. specially developed for fast rotating applications Very low coefficients of friction Excellent wear resistance

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® J4 - low cost and low wear Lubricant- and maintenance-free Low-cost-material for large volumes Low coefficients of friction Media resistant Lowest humidity absorption Diameter [mm]: length [mm]: Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

iglidur® J3: runs longer iglidur® J3 is our new material with increased wear resistance at low to medium loads and high speeds. The service life is up to 300% higher than in iglidur® J, the proven top endurance runner material. iglidur® J3 is available as cylindrical bearings and plain bearings with flange. Lubricants and maintenance-free Low coefficient of friction Good resistance to media Lowest humidity absorption PTFE free

Request for a quote

IGUS® GMBH

Germany

Lubricant- and mainteance-free Easy to cut Adherent For compact areas Typical applications:Mechanical engineering, materials handling, fixture construction, installation technology, etc. iglidur® Tribo-Tape A180 Delivery program: iglidur® Tribo-Tape V400 Delivery program: Material: iglidur® A160 Low coefficient of friction Best wear-resistance Upto +100 °C Compared to similar thin plastic films, the cost-effective iglidur® A160 tape has a very high wear resistance. Material: iglidur® V400 Extremely wear resistant Highly resistant to media Upto +200 °C The extremely wear-resistant and at the same time very media- and temperature-resistant iglidur® V400 tape shows up to 10 times higher wear resistance in the test compared to special products for machine beds and the like. Lubricant- and mainteance-free Easy to cut Adherent For compact areas Typical applications:Mechanical engineering, materials handling, fixture construction, installation technology, etc. Wear rotating against stainless steel pin (1.4305) F= 35 N, v= 0.5 m/min Y = Wear/mass decrease [mg/km] A = PC | B = compound liner | C = PEEK D = PEEK mod. 1 | E = PEEK mod. 2 | F = PET G = iglidur® A160 Wear rotating against stainless steel pin (1.4305) F= 35 N, v= 0,5 m/min Y = Wear/mass decrease [mg/km] A = iglidur® V400 | B = PTFE bronze compound iglidur® Tribo-Tape A180 Delivery program: iglidur® Tribo-Tape V400 Delivery program:

Request for a quote

IGUS® GMBH

Germany

iglidur® JATM, metric d1 [mm]: iglidur® JATM/VATM consists of a hard-anodized ring and a bearing ring made of iglidur® J (JATM) and iglidur® V400 (VATM). These glide pairings fetch low coefficients of friction and high wear resistance - without lubrication. Special features Maintenance-free plain bearing system For high service performances High stiffening Simple installation Material: iglidur® J High temperature options VATM, iglidur® V400 More dimensions and supplies on request When to use it? When an axial bearing system with defined gliding partners is desired When extremely high wear resistance is required When a very low coefficient of friction is desired When not to use it? When an additional angle compensation is required igubal® axial bearing When little mounting space is available iglidur® J When only sporadic movements are present iglidur® G Y = wear [μm/km] Figure 36.1: The diagram shows the influence of load (p in MPa) and speed (v in m/s) on the wear of the axial bearing. Y= Coefficient of friction Figure 36.2: In the test with different speeds (v) and loads (p) the coefficients of friction of the bearing systems were determined (v in m/s, p in MPa). iglidur® JATM, metric d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® H4: The Automotive-Standard. Very cost-efficient high-temperature material with good dry-operation properties and "engine compartment resistance". iglidur® H4 is available as cylindrical bearings and plain bearings with flange. Low friction coefficient Best wear-resistance high temperature resistance -40 °C up to +200 °C

Request for a quote

IGUS® GMBH

Germany

iglidur® C500 Up to +250 °C, wear-resistant. iglidur® C500 can be used up to 250 °C, extremely media-resistant – including in cleaning processes with hydrogen peroxide – wear resistant, with low friction values. Also suited for a wide range of custom geometries or piston rings. High resistance to media and temperature Long-term service temperature +250°C Good coefficients of friction and wear Lubricant- and mainteance-free

Request for a quote

IGUS® GMBH

Germany

iglidur® D: low cost material with silicon Low-cost-material with low coefficients of friction and good wear resistance at low loads. iglidur® D is available as cylindrical bearings and plain bearings with flange. Low coefficients of friction at high speeds For low loads Very cost-effective Vibration-damping Lowest humidity absorption

Request for a quote

IGUS® GMBH

Germany

iglidur® R Low-cost-material with low coefficients of friction and good wear resistance at low to medium loads. iglidur® R is available as cylindrical bearings and plain bearings with flange. Good abrasion resistance Low coeffi cients of friction while running dry Very cost-effective Lowest humidity absorption

Request for a quote

IGUS® GMBH

Germany

25 dimensions - ex stock iglidur® Plain bearing - Product overview New as standard range: iglidur® J4 is the new low-cost material for long lifetimes for low to medium loads. Zero lubrication, zero maintenance Low-cost-material for large volumes Low coefficients of friction Media resistant Lowest humidity absorption Bearings made of iglidur® J4 in a satellite receiving unit material data: iglidur® J4 Density 1,48 g/cm 3 Colour Gray Max. moisture absorption at 23°C and 50% r.h.: 0,3 weight-% Max. water absorption 1,3 weight-% Upper long-term application temperature 90°C Upper short-term application temperature 120°C Lower application temperature -50°C Bending E-module 2.350 MPa Max. surface pressure 35 MPa Surface resistance >10 12Ω 25 dimensions - ex stock

Request for a quote

IGUS® GMBH

Germany

iglidur® W300: The endurance runner The specialist for extremely high wear resistance, also for rugged shafts or especially abrasive environmental media. Attain maximum holding times in your applications with iglidur® W300. Dimensions according to ISO 3547-1 and special dimensions. iglidur® W300 is available as cylindrical bearings, plain bearings with flange and thrust washers. For extremely high service life in continuous operation Low friction value Extremely high wear-resistance Suited for rough shafts and stainless steel shafts Dirt resistant

Request for a quote

IGUS® GMBH

Germany

Diameter [mm]: length [mm]: iglidur® W300 - Material data iglidur® W300 - The continuous runner for maximum holding times. iglidur® W300 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview iglidur® W300: The endurance runner For extremely high service life in continuous operation Low coefficient of friction extreme high wear-resistance Suited for rough shafts and stainless steel shafts Dirt resistant Diameter [mm]: length [mm]: iglidur® W300 - Material data iglidur® W300 - The continuous runner for maximum holding times. iglidur® W300 - Material data Polymer bearings applications overview Polymere bearings application examples overview Polymer bearings applications overview

Request for a quote

IGUS® GMBH

Germany

igubal® spherical balls W..M/I Standard spherical ball - dimensional series K and E in metric and inch dimensions igubal® spherical balls W..M/I igubal® spherical balls R...M Low cost spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls R...M igubal® spherical balls X...M Spherical ball for high temperatures - dimensional series K and E in metric dimensions igubal® spherical balls X...M igubal® spherical balls J...M, mm Spherical ball for low humidity absorption - dimensional series K and E in metric dimensions igubal® spherical balls J...M, mm igubal® spherical balls J...M, large dimensions, mm Spherical ball for low humidity absorption - dimensional series K in metric dimensions igubal® spherical balls J...M, large dimensions, mm igubal® spherical balls JKM-GT split, mm Splitted spherical ball for low moisture absorption - Dimensional series K in metric dimensions igubal® spherical balls JKM-GT split, mm igubal® spherical balls UWEM Spherical ball for underwater applications - dimensional series E in metric dimensions igubal® spherical balls UWEM igubal® clearance-free balls J4VEM, mm Clearance-free spherical balls through camber, dimensional series E igubal® clearance-free balls J4VEM, mm igubal® spherical balls J4...M, mm Low priced spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls J4...M, mm igubal®-spherical balls RN248..M, mm Detectable spherical ball - dimensional series K and E in metric dimensions igubal®-spherical balls RN248..M, mm Every iglidur® material possesses a series of special properties which account for its suitability for certain applications and requirements. Currently we offer you spherical balls made of iglidur® materials W300 (standard), J, J4, R, UW and X. igubal® spherical bearings application examples Special properties: maintenance-free dry operation Corrosion resistant High compressive strength High elasticity Very low weight Various materials Spherical balls - material properties iglidur® W300 (Standard) – very wear-resistant material iglidur® R cost-efficient and low coefficients of friction iglidur® X resistant to temperature and chemicals iglidur® J low coefficients of friction and low humidity absorption iglidur® UW suited for underwater applications Tolerances Maintenance-free igubal® spherical balls are designed with a tolerance in the inner diameter according to E10. The shaft should have a tolerance between h6 and h9. When to use it? When maintenance-free materials are required When components of the dimensional series E and K should be used When different iglidur® materials should be tested When high compressive strength is required When high elasticity is required When not to use? When temperatures above +250°C prevail When dimensions over 50 mm are needed When rotation speeds in excess of 0,5 m/s should be implemented igubal® spherical balls W..M/I Standard spherical ball - dimensional series K and E in metric and inch dimensions igubal® spherical balls W..M/I igubal® spherical balls R...M Low cost spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls R...M igubal® spherical balls X...M Spherical ball for high temperatures - dimensional series K and E in metric dimensions igubal® spherical balls X...M igubal® spherical balls J...M, mm Spherical ball for low humidity absorption - dimensional series K and E in metric dimensions igubal® spherical balls J...M, mm igubal® spherical balls J...M, large dimensions, mm Spherical ball for low humidity absorption - dimensional series K in metric dimensions igubal® spherical balls J...M, large dimensions, mm igubal® spherical balls JKM-GT split, mm Splitted spherical ball for low moisture absorption - Dimensional series K in metric dimensions igubal® spherical balls JKM-GT split, mm igubal® spherical balls UWEM Spherical ball for underwater applications - dimensional series E in metric dimensions igubal® spherical balls UWEM igubal® clearance-free balls J4VEM, mm Clearance-free spherical balls through camber, dimensional series E igubal® clearance-free balls J4VEM, mm igubal® spherical balls J4...M, mm Low priced spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls J4...M, mm igubal®-spherical balls RN248..M, mm Detectable spherical ball - dimensional series K and E in metric dimensions igubal®-spherical balls RN248..M, mm

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling bearings at operating temperatures of -50°C to +180°C For long-term lubrication of temperature-stressed electric motor bearings, e.g. in household appliances or of bearings which are to start up easily at low temperatures Initial lubrication of roller bearings, such as ball bearings that are open, closed on one side, or sealed off on both sides Advantages and benefits Broad range of uses outside normal grease performance areas Reduces wear and friction High resistance to oxidation Wide operating temperature range and good low-temperature properties Very good corrosion protection Very good compatibility with most plastics and elastomers

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flow meter with display convinces with its simple, demand-oriented display, operability and compact design. Thanks to the rotating Oval gear meter and a magnet integrated in the measuring chamber, it enables the exact measurement of the volume flow and measures mineral oils and alternative fuels such as diesel, petrol etc. precisely, quickly and above all efficiently. * Media examples: Diesel, heating oil, hydraulic oil, machine oil and motor oil etc. * Quantity preselection can be retrofitted with a relay module at any time * Suitable for measuring alternative fuels Features & Advantages * Measurement according to the oval wheel principle * High measuring accuracy * Low pressure losses in the system * Measuring range from 3 l/min - 80 l/min * Low frictional resistance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to its high resolution also when measuring long distances, linear displacement measurements up to 900 mm can be carried out. Conversions between rotatory and translation movements through ball screws, wire or cord connections and so on are not necessary for direct displacement measurement. Application fields include: —Electromagnets —Deformations - bending —Pneumatic cylinders —Length tolerances —Press-insertions (longitudinal press-fits) —Feed strokes —Machine hubs —Punch, knee lever or extruder distances —Hydraulic cylinders Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The rod is guided in a low-play floating frontal bearing. This absorbs small angular and parallel displacements.

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex secuGrip90laminate secuGrip90 laminate is our new, selfadhesive antistick laminate that you can apply yourself. The secuGrip90 coating, which is up to 2 mm thick, features a high coefficient of friction and is extremely abrasion resistant. Application is easy The reverse side is coated with an acrylate adhesive designed to stick to a variety of smooth surfaces including Metals, glass, ceramic, stone, paper & cardboard, fabric, various plastics and soft plastics. Features of the acrylate adhesive high adhesive strength temperature and weather resistant tolerates moisture well equalises tension

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The high resolution allows linear measurements to be accurately sized even in large measurement ranges. Conversion of rotatory and translational motion by spindles, wires or others is not necessary for direct displacement measurement. Areas of application are: —Hydraulic and pneumatic cylinders —Detection of positions on coordinate —Inspection machines —Displacement of plungers, knee levers or extruders —Coil and de coil lengths —Strokes on chassis —Metering strokes Displacement sensors model 8718, using a resistance track made of conductive plastic material, are suitable for direct, accurate and absolute measurements of displacements and lengths. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The vibration-cushioned slider allows a clear signal output even by slight shocks or high operating speeds up to 10 m/s.

Request for a quote

MINEON HANDEL GMBH

Germany

Aluminum Alloy Hinge, POM shaft,Size:65*55mm,Torque strength canbe adjusted by screwdriver,Easy Installation,ROHS compliance.

Request for a quote

MINEON HANDEL GMBH

Germany

Zinc Alloy Hinge,Size:38*40mm and 57.1*50.8mm available,with different standard Torque 1.4/1.8/2.3/3.4N.m.Technical requirements:After 20,000 times lifespan,the torque attenuation deviation is ± 20%

Request for a quote

MINEON HANDEL GMBH

Germany

Black POM Hinge,Size:43*36mm and 63.5*57.5mm available,Torque strength canbe adjusted by screwdriver.Easy Installation,ROHS compliance.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Roller chains with elastomer profiles are ideal for applicationswhere fragile goods require gentle conveyor handling. ELITE chains are used for transporting goods that should not be scratched, such as coated or thin sheet metal, planed timber planks or pipes. The material iwis uses for the ELITE product range is nitrile butadiene rubber (NBR) with a hardness of 80 Shore A. NBR offers the optimum combination of cohesive friction, abrasion resistance and durability. Other profile types are possible for special applications and can be supplied on request. ELITE highlights: • All ELITE chain plates 1 are tapered and shot-blasted; production processes such as fine blanking and ball-drifting ensure a particularly high contact ratio • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • The standard rubber profile 3 is nitrile butadiene rubber (NBR) with a hardness of 80 Shore A.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The FLEXON maxxTop product range offers both stainless steel and plastic flat top chains. The range also includes conveyor chains made of cast iron and plastic, as well as straight running and sideflexing plate top conveyor chains. FLEXON stainless steel and plastic flat top chains are available as straight running or sideflexing versions, in a variety of materials, widths and plate thicknesses. Featuring low friction values, high resistance to wear, good noise damping, high-quality workmanship and surface finishes, they are widely used in the beverage industry and beyond. iwis Stainless steel flat top chains made of hardened material, which offers excellent tensile strength, corrosion and abrasion resistance. Highlights: - Increased wear resistance - Corrosion-proof - Better wear and corrosion properties when compared to carbon steel equivalent - Available in most standard sizes

Request for a quote

BEULCO GMBH & CO. KG

Germany

With BEULCO BlackLine® the next generation of plastic connectors has emerged. Function and material are aligned in a way that highest possible safety and best comfort are given during installation. The connectors are made of extremely resistant high performance material (PP and POM). It is characterized by high strength and hardness in a wide range of temperatures. Additional features as the high heat resistance, a low friction coefficient and a minor water absorption make the material coparable to metal. It is resistant against UV, chemicals and corrosion.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

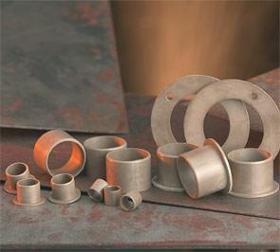

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quoteResults for

Friction-resistant - Import exportNumber of results

33 ProductsCountries

Company type