- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fan units

Results for

Fan units - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

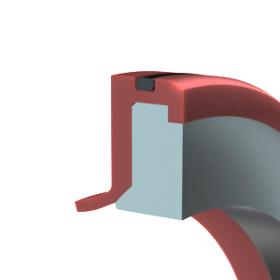

Motor shafts. Gear and frive unit shafts. Fan shafts. Clamping tools. Applications at high speed and lo pressure.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

For forced cooling, Seifert electronic offers compact fan units in various performance classes. The variable fin spacing in the high-performance heat sinks ensures strong cooling during fan operation. In forced convection cooling, fans are required as separate sources of convection. To ensure optimal convection during fan operation, it is recommended to incorporate heat sink profiles. The fin spacing in heat sink profiles is particularly important, as increasing the surface area is key for forced cooling. To push this boundary further, we have continuously reduced the fin spacing in our profiles. Depending on the model, up to three fans per cooler are possible, which can optionally be equipped with pressure chambers for improved air guidance. Most heat sinks are already equipped with aerodynamically designed hollow fins. Additionally, air deflectors for air guidance are available for some heat sink profiles.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Compact filters are characterised by the fact that they essentially unite fan, filter element and discharge or dust collection facility in one. The capacity range of the compact filters extends up to 20,000 m³/h. Different systems and modes of operation are available for the individual assemblies, resulting in a large number of possible variants. This allows us to offer a large range of solutions for dedusting tasks. Based on our many years of experience, we select the filter media from those available on the market that are best suited for the most diverse types of dust and tasks. Filter hoses, filter bags, filter tubes and filter cartridges are used as filter elements. Cleaning takes place using compressed air impulse, low-pressure purge-air or shaking. Fans from own development and production enable us to design a highly efficient and precise layout. Discharge usually takes place directly into collecting containers, such as dustbins with snap fasteners, or into containers, big bags, or via discharge mechanisms into automatic disposal systems. Screw conveyors, drag conveyors, rotary systems, cellular wheel sluices, double-gate sluices and slidegate valves are available as discharge mechanisms. Intelligent control systems, piping elements, silencers and pre-coating devices for auxiliary dusts are standard items in the range. Naturally we also use our know-how to create needs-based custom solutions.

Request for a quote

PERO AG

Germany

The ROTIMAT 1A has been designed for the spray cleaning of all workpieces that can be placed in the sturdy rotating basket. After production or repair, the workpieces and parts are cleaned with a hot aqueous cleaning medium that is sprayed onto the parts from all sides. The unit can be loaded from the front, or from the top, using lifting gear. The compact machine is equipped with four castors for easy relocation within the factory. Cleaning with aqueous media (acidic, neutral or alkaline) Universell cleaning unit for many different workpieces Compact portable unit with castors Drying without external heat input, or with optional extractor fan Available as 1bath unit with loading of the unit via Manual loading

Request for a quote

KAMPMANN GMBH & CO. KG

Germany

EC technology: New EC technology is a revolution in electronic drive technology. It enables precise adjustment to output requirements thanks to its continuously variable operation. Easy installation Drill 4 x, screw and KaCool W is already on the wall. It could hardly be easier to work with! And if the need is not known beforehand: now you know how easy it is to retrofit the KaCool W. Variety of variants The product range gives you freedom of choice: on-site or separate infra-red control, or a wide selection from the Kampmann control range Easy access All the components are compactly installed inside the unit and so are easily accessible. Discreet Elegant enough to notice - discreet enough not to stand out. Subtly creating the perfect climate.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The filter housing is made of sturdy steel plate with a reinforcement of structural steel frame. Equipped with inlet and outlet openings for the dusty or filtered air. The inspection cap is used to control the automatic filter and has a flap for access to the built-in filter cartridges. These are made of folded polyester material having a filter area of each of 8 and 14 m². Provided with upper and lower reinforcing rings of plastics material for fastening in the holders. The dust drawer is equipped with wheels, allowing easy extraction during disposal of the dust. The centrifugal fan with a flanged electric motor and the fan / motor unit is built up in the filter housing - the motor is bolted with its flanges on the filter housing and surrounded by the sound enclosure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Fan units - Import exportNumber of results

6 ProductsCountries

Company type