- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dosing system

Results for

Dosing system - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP22 as a volumetric dosing pump for larger volumes ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - drive with servo or three-phase motor - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming mode of operation

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP18 as a volumetric dosing pump for larger volumes ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - drive with servo or three-phase motor - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming operation

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

2-component dosing solution with optimum installation space design cascadable multiple dosing system with small dosing head distances minimum space requirement in automation systems. The ViscoDuo-P 4/4 2-component dispenser is a valveless, static, space-saving mixing head with dispensers arranged directly in front of the mixer. The EC version dispensers have been specially designed for easy cleaning (Easy-Clean) and checking of the pump interior. No valves are required in the mixing head. The components to be mixed are metered into the static mixing tube purely volumetrically via the dispenser without dead space. Your advantages: - Processing of viscous materials, unfilled as well as very highly filled supply of the medium with only low inlet pressure - Setting the desired mixing ratio by adjusting the speed ratio of the two dispensers - sensors integrated without dead space in each component for online process monitoring - Withdrawal possible

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The compact 3RD4-EC dispenser from ViscoTec ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products. Absolutely precise, uniform and reliable dosing of various media, such as adhesive dosing or sealant dosing, thanks to the special rotor-stator geometry. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - interior non-stick coated - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - long service life due to media-specific component selection - easy cleaning and condition check of the pump interior - quick disassembly

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP36 is a volumetric dosing pump of larger volumes for an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - Drive with spur gear motor and optional forced cooling fan - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming operation

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Lutz-Jesco dry material feeders are precise and reliable devices for volumetric conveying of pourable substances. These devices consist of self-supporting welded constructions made of high-quality stainless steel sheet, which ensures their robustness and durability. Available in various conveying capacities, the dry material feeders offer flexible adaptation to different requirements and areas of application. They are equipped with hollow screws (screw spindles), which ensure even and continuous material transport. Thanks to this technology, they can feed a wide range of bulk materials, including fine dust particles, pellets, flakes and short fibres. Lutz-Jesco dry material feeders are ideal for industrial applications where precise dosing is required, such as in the chemical industry, food processing and many other sectors.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

In order to avoid chemical reactions such as curing or crystallization during the dosing process, any contact with metal in the area in contact with the material in the dispenser was avoided. The materials used have been carefully selected: On the one hand with regard to chemical resistance to adhesives and other fluids and on the other hand with regard to highest resistance to physical wear by abrasive media. Highly reactive materials such as sulfuric acid, anaerobic UV curing acrylates and electrolytes require special treatment. They can be dosed with highest accuracy and best repeatability. The new metal-free dispenser can be easily installed on existing ViscoTec drive technologies and offers the same advantages as other proven dispensers from the portfolio of the dosing technology specialist. The metal-free dispenser is available in many sizes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The eco-PEN330 precision volume dispenser made by ViscoTec enables many applications in the low to high viscosity dispensing range. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. - True volumetric dosing - Retreat effect - Viscosity-independent dosing - Easy cleaning - dosing independent of inlet pressure - Adjustable dosing flow - Pressure-tight without valve - Dosing pressures from 16 to 20 bar

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Examples of materials for dosing: 1- and 2-component epoxy, UV / light-curing / thermosetting adhesives, highly filled materials, anaerobic adhesives, shear-sensitive adhesives, heat-conducting paste, sealants, flavourings, silver conductive paste, flux, perfume, isopropanol, industrial oils, silicone, alcohol, grease, paint and ink, MEK, braze paste, PU, acetone, petrol and many others. The preeflow® eco-DUO is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. Application: - point dosing, with highest volumetric accuracy - bead application with application speed adjustable to the web speed - Potting technology

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

lacquer supplis for the internal coating of tubes an aerosol cans

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

paint supply units for rolling and spray lacquer in the external decoration

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Our systems dose in parallel into stationary and mobile tanks. The systems work with mass flow meters or measuring cells and scales. Dosing cluster ■ Dosing of large components for mixtures up to 12 tonnes ■ Stationary or mobile tanks ■ Flow rate: 30 - 250 litres/min ■ Parallel dosing with several scales or with mass flow meters ■ Barcode-supported dosing ■ Unattended operation ■ Integrated suction on the dosing cluster ■ Different weighing ranges ■ Explosion protection according to Atex The advantages are obvious: simply add the remaining large components to your premixes - in a single additional work step - and of course with barcode support and fully automatically. With our modern storage systems, you can remove large components from several drums simultaneously at any time. Labour and cleaning-intensive pumping from drums into mixing containers is a thing of the past.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ up to 16 fully automatic mixing recipes during the unattended night shift ■ scale sizes: 300/600 kgs; 1 g / 2 g indicated scale resolution ■ dosing accuracy: +/- 5 g / +/- 6 g ■ parallel dosing on several scales ■ valve sizes from DN 15 to DN 50 ■ fast adaptation to dosing containers between 75 litres and 600 litres ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound extraction system directly at the dosing point ■ Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 mixes automatically in night mode ■ 2000 doses per day ■ Liquid dosing up to 25 kg batch size ■ Scales with 30 kg or 60 kg capacity and 10 mg or 20 mg indicated scale resolution ■ 50 mg or 60 mg dosing accuracy ■ DN 8 valves ■ Parallel dosing for high speed ■ Barcode-supported dosing ■ Customisable system sizes and container transport systems ■ Integrated environmentally friendly extraction system ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing system for laboratory and small scale production mixes up to 6 kg batch size Space-saving this system combines all advantages of a laboratory dosing system to the production capacity of the larger systems Concordia II – V (C 2 – 5). ■ batch sizes up to 6 kg ■ more than 130 fully automatic mixing recipes during the unattended night shift ■ 7000 dosing cycles per day ■ dosing precision on the 6 kg scale: +/- 5 mg ■ smallest dosable quantity on the 6 kg scale: 20 mg ■ modular design for up to 1000 components ■ barcode assisted dosing ■ high dosing speed through parallel dosing on several scales ■ individual container transport Systems ■ various raw material storage Systems ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The Dosing Star is characterised by its very high dosing accuracy at maximum dosing speed. The design is modular. Each module has its own scale. In addition to the variable number of dosing modules with the valve containers, the Dosing Star has a linear gantry for distributing the batch containers to the individual modules. Up to 25 mixing containers are each placed on a tray trolley. Four trolleys can now be conveniently pushed into the system. Thanks to the modular design of the dosing system, it is possible to connect up to 8 dosing modules to the linear gantry. A maximum of 128 valve containers can be stored in each of the dosing modules. ■ Fast dosing in containers with an opening diameter from approx. 15 mm ■ Gripping system for time-optimised distribution of the mixing containers to up to 8 dosing modules ■ Fixed and flexible barcodes can be used ■ Rush orders are optimally integrated into the production process

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Creative and sampling laboratories are familiar with the problem: cramped premises with no alternatives, hardly any space for the extensive ingredients and tight deadlines. Specially developed for office buildings, the modular and space-saving laboratory systems can automate up to 600 components with maximum precision. From now on, fast presentations of mixtures will be a further advantage for your company. ■ 34 mixtures fully automatically in unattended night-time operation ■ Optionally up to 54 mixes ■ 2,000 doses per day ■ Barcode-supported dosing ■ Dosing accuracy with 6 kg scale: ±3 mg ■ Smallest dosing quantity with 6 kg scale: 5 mg ■ Mixtures up to 1 000 ml ■ Quick presentation of dosing results ■ cooled and heated components ■ Modular design for different sizes (100-500 components) ■ Integrated storage system

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Dosing systems for all common lubricants. With the Jerko concentration calculator you get always the right mixture no matter what density the medium has. The dosing systems are available as stand alone solutions or as an optimal addition to our systems or existing spraying system.

Request for a quote

MPT DOSING GMBH

Germany

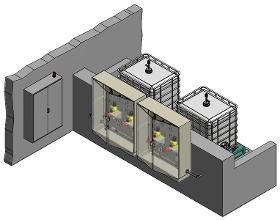

From left to right Dosing system for acid (left) and caustic (right). Sodium hydroxide-dosing system. Chemical-dosing systems are developed and manufactured for various applications and processes as complete, ready-for-connection function modules. Selecting the components and materials for constructing these systems requires long-year experience and comprehensive knowledge of the specific properties of the substances to be dosed. A lot of media are toxic and harmful to persons. Moreover, many are harmful to the environment and the groundwater. Substance properties such as a high viscosity or a high vapor pressure compromise the liability and a safe function if not considered when selecting and installing the pumps. For many years, MPT staff has been working in this specific area and gathered much experience when implementing hundreds of applications for nearly each topic in the range of premium dosing technology. From left to right Sulfuric acid-dosing station. Hardness

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

SPECTROPLUS is a gravimetric & volumetric synchronous dosing & mixing unit for diverse materials – from granules, regrind or powders to liquids and flakes. Due to the modular design of the SPECTROPLUS with only one frame size and up to 8 dosing module positions, it is one of the most flexible overall systems in the motan product world. In addition to the gravimetric and volumetric version, the SPECTROPLUS can also be combined (gravimetric and volumetric dosing modules in combination). This makes it ideal for individual applications and also complex end products. motan's SPECTROFLEX units can easily be added to the SPECTROPLUS.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoDuo-VM 2-component dispenser is a valveless dosing system for static mixing based on the proven progressive cavity technology and thanks to its purely volumetric precise dosing principle, is ideally suited for high-precision dosing tasks. Built according to modular structure, a configuration of the 2-component dosing systems as well as maintenance and part exchange at module level is possible. The material components are mixed downstream of the mixing head only in the mixing tube to prevent material hardening in the system components of the mixing head. Your advantages: - repeatable dosing volume even with viscosity and density fluctuations - Processing of low to high viscosity materials with low to very high filler content - Dispenser and mixing head segments can be combined in size due to modularity - standard equipment with dead space-free integrated dosing pressure sensors for online process monitoring - simple assembly/disassembly of the components

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised dosing systems for you. Volumetric dosing is carried out on a quantity basis by measuring the flow rate of liquids or bulk materials. Application-dependent measuring systems are used in our volumetric dosing systems. These make it possible to provide the specified quantity of material at a defined point in time in a defined ratio. The continuous inline dosing via flow measurement technology or dosing pumps with linear characteristic curve enables recipe-accurate dosing of liquids and bulk materials in a small space.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Application: Point dosing with highest volumetric accuracy - bead application with application speed adjustable to the web speed - encapsulation technology Areas of responsibility: - Electronic components - Semiconductor production - LCD/LED/OLED - Photovoltaics - Medical technology - Biochemistry - Laboratory - Optics and Photonics - SMD/SMT Technical Data: - True volumetric dosing - Retraction effect - Viscosity independent dosing - Easy cleaning - Inlet pressure independent dosing - Adjustable dosing flow - Pressure tight without valve - Dosing pressures up to 40 bar

Request for a quoteResults for

Dosing system - Import exportNumber of results

120 ProductsCountries

Company type

Category

- Weighing and dosing equipment (28)

- Dosing pumps (22)

- Goods handling systems, continuous (12)

- Pharmaceutical industry - machinery and equipment (12)

- Dosing - machines and equipment (8)

- Plastics - machines and material for industry (6)

- Wood veneer - machinery and equipment (4)

- Bottling and filling - machinery and equipment (2)

- Cleaning and maintenance - equipment and supplies (2)

- Conveyor systems (2)

- LPG (2)

- Packing and packaging - machinery and equipment (2)

- Varnishing equipment (2)

- Pumps (1)

- Applicators for adhesives and glues (1)

- Flowmeters (1)

- Boilers, industrial (1)

- Cosmetics industry - machinery and equipment (1)

- Laboratory equipment and instruments (1)

- Measurement - Equipment & Instruments (1)