- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- damping

Results for

Damping - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

For the majority of the CSN® Filter and Damping Resistors the design is based on CSN® Resistor Webs. The resistor units provide operation at high continuous power, excellence voltage strength and low inductivity while needing only little space. CSN® Filter Resistors are used in HVDC applications as well as in reactive power compensation applications (like SVC, MSCDN, STATCOM) all over the world and have proven their reliability – even under harsh environmental conditions – for long time periods. CSN® Damping Resistors are most often used for buildingup RCcircuits in industrial plants as well as for damping of magnetic cores and reactors. The CSN® Filter and Damping Resistors are characterized by proven design for both, indoor and outdoor applications excellent high voltage strength high specific load due to very good convection conditions low inductance and capacity longterm stability low weight nearly unlimited adaptability to specified applications

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS takes measures against vibrations in deep drilling procedures Deep drilling procedures with drilling rods with a long overhang are one of the most demanding tasks in cutting technologies. What influences vibration, what amplitudes does it create, what is the effect of superimposed vibration and when are uncontrollable resonances encountered? All these are questions that are difficult to answer using theory alone. These findings formed the basis for the new development of EWS Rigid. The objective was to create a drilling holder with a passive damping system to counteract the vibrations that are created. This involves using variable vibration dampers with linear degrees of freedom in a floating mounting inside the cutter carrier. The damper position is set using a radially mounted setscrew, which allows optimum vibration conditions to be created. The improvement in surface qualities of bores is significant, as is the increase in the service life of cutter tools.

Request for a quote

ROLLON GMBH

Germany

The Hegra Rail family includes various telescopic guide profiles with ball cage capable of handling high loads up to 20 kN per pair, overextensions up to 200% of the length of the guide in closed position and available in different materials such as steel, aluminium or stainless steel AISI 304 and AISI 316. The main features of the Hegra Rail telescopic guides: handling of heavy loads combined with minimal bending profiles with 1, 2 or 3 moving elements for extensions up to 200% available in different materials: steel, aluminium, stainless steel AISI 304 and AISI 316 high rigidity and moment of inertia with thin sections fluid noiseless operation long working life extremely reliable The Hegra Rail family of telescopic guides includes five product categories: partial and full extensions, overextensions, heavy loads and S-sections. Telescopic guides for partial extensions,Telescopic guides for full extensions,Telescopic guides for overextensions,Telescopic guides for heavy loads

Request for a quote

ROLLON GMBH

Germany

High load capacity and reduced deflection telescopic rails with caged balls bearings. The telescopic guides have optimal running properties due to inductively hardened raceways. TELESCOPIC RAIL linear slides exhibit little deflection while under very heavy loads, even when fully extended. Telescopic guides come in eight different series (DS, DSE, DSC, DE, DBN, DMS, ASN, DRT) Torsionally rigid intermediate elements with S-shaped, double-T, or squared sections Over-extending, full or partial telescopic strokes are available In the DMS63 Series the supported load can reach 2,000kg per pair. Extremely low deflection and smoothness of movement even in high load, 24/7 applications Some Series can be locked in the closed position Special versions and strokes available upon request The Telescopic Rail product family includes full or partial extraction telescopic rails, and consists of eight (8) different sizes. The deflection resistant central components are available in the S, double T...

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Damping cushions made of stainless steel are knitted and pressed in a special process. Depending on size, density and design it can be loaded in a range between 5 and 20.000 kg. It can be pressed in cylindrical or rectangular shape. Versions with bunches and steps are available. Standard materials are 1.4301 and 1.4404. Additional materials and special designs are on demand. RG+ offers the following damping cushions as standard elements: GKK as a vibration damper in cylindrical form GKR as a vibration damper in rectangular form GKB as a vibration damper with a bunch

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

Due to many years of experience in the field of damping technology, LEBEN is able to replace shock absorbers of other makes from various manufacturers. The required characteristics of the damping property as well as the dimensions of these industrial shock absorbers to be replaced can usually be met by a replacement shock absorber made by LEBENDämpfungstechnik GmbH.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Confectioning and Combinable Energy capacity max. 15.0 Nm/cycle Stroke 6.5 mm Tailor made damping material in pad format: SLAB damping pads are made of a viscoelastic PUR-material. They absorb impact loads extremely effectively and are also suitable for insulating or damping vibration. The pad series SL-030 to SL-300 are quickly adapted to the relevant type of application. This is in part achieved through the configuration of the calculating tool or directly by the ACE specialist engineers. Furthermore, this is possible because the standard material can be cut exactly and quickly to any customer requirement with our new cutting system. It is also possible to obtain a sample to find an optimum solution.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Confectioning and Combinable Energy capacity max. 6.7 Nm/cycle Stroke 12.5 mm Tailor made damping material in pad format: SLAB damping pads are made of a viscoelastic PUR-material. They absorb impact loads extremely effectively and are also suitable for insulating or damping vibration. The pad series SL-030 to SL-300 are quickly adapted to the relevant type of application. This is in part achieved through the configuration of the calculating tool or directly by the ACE specialist engineers. Furthermore, this is possible because the standard material can be cut exactly and quickly to any customer requirement with our new cutting system. It is also possible to obtain a sample to find an optimum solution.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Confectioning and Combinable Energy capacity max. 3.1 Nm/cycle Stroke 6.5 mm Tailor made damping material in pad format: SLAB damping pads are made of a viscoelastic PUR-material. They absorb impact loads extremely effectively and are also suitable for insulating or damping vibration. The pad series SL-030 to SL-300 are quickly adapted to the relevant type of application. This is in part achieved through the configuration of the calculating tool or directly by the ACE specialist engineers. Furthermore, this is possible because the standard material can be cut exactly and quickly to any customer requirement with our new cutting system. It is also possible to obtain a sample to find an optimum solution.

Request for a quote

R+L HYDRAULICS GMBH

Germany

Low cost noise reduction Effective damping Resistance against mineraloil

Request for a quote

R+L HYDRAULICS GMBH

Germany

Design acc. VDMA 24 561 Damped versions Eaasy replacement Spacesaving Pressure up to 16 bars

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The damping fluid used by LEBENDämpfungstechnik GmbH is used with different consistency under the name COMPENSOL®. Each damping medium can be chosen to meet the requirements. We provide the ideal hydraulic oil (socalled medium) for use in temperaturecontrolled indoor areas up to extreme high temperatures or low temperatures. For special applications, e.g. at temperatures above +80° C or below 40° C, we use a pastelike dispersion as damping medium. This medium solidifies at rest to an apparently solid mass and only becomes flowable under the action of force. When the load ends, it returns to its apparently solid original state. This dispersion has the following properties chemically a colloidal solid dispersion physically a nonNewtonian pseudo plastic Bingham fluid with viscous properties It is a paste or better a coagulation structure and deforms plastically under mechanical stress.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Damping effect Where forces collide, materials are often unintentionally damaged. Impact damage to goods and stock often occurs due to carelessness, negligence, recklessness, improper handling or a lack of protection. secutex – buffer pad has a damping effect everywhere where products can be damaged under their own weight or during handling. In addition, foam coatings and hollow sections, which deform under loading, increase the damping effect, such as, for example, in secutex – Soft, secutex – SoftPad and secutex – Hollow Profile. Antislip effect secutex prevents loads from slipping and slipping off during transport. In tests, secutex scored higher than all comparable materials. secutex not only meets the standard, it exceeds the friction coefficient values standard currently in force. For wet or oily surfaces we recommend secutex with textured surfaces. Direct material contact is thereby reestablished. Noisereducing effect

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI–PA MILLED FREQUENCY DAMPED contact disc is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the NBR coating of the contact disk. This means that – during the belt grinding process – both the noise level is reduced to a minimum and the material removal rate is increased to a maximum. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. The contact disks are very aggressive when used due to the grooves they contain. The aggressiveness effect of the contact disk can also be optimized for each application with the milled frequency-damped contact disk by means of an individually optimized groove width-groove depth-web width ratio. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide polyurethane lamellae are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating resp. the length of the polyurethane and plastic foam lamellae can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range in the contact wheel coating during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-PUS/KS frequency damped achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide lamellae of foamed up Vulkollan® are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range generated during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-KS/V FREQUENCY DAMPED achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact disc FAPI-VU MILLED FREQUENCY DAMPED is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the contact disc’s foamed Vulkollan® covering. This reduces the noise level to a minimum during the belt grinding process and increases the removal rate to a maximum. The aggressiveness effect of the contact disk can also be optimized for each application using an individually optimized groove width-groove depth-web width ratio for milled, frequency-damped contact disks so that high-performance processes are possible. As with all contact discs in the VU series, there are no signs of fatigue after long, intensive use.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan® by its slightly yellowish color. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

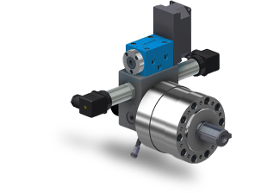

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors of the HSE series also fulfill the function of end position damping with or without adjustable swivel angle limitation. This refers to braking, the deceleration of the swivel movement to a standstill. For damping, the cross-section of the bore for the outflowing medium is continuously reduced, thus hydraulically slowing down the moving masses. The end position is reached when the hole is completely closed and the medium can no longer flow out. In order to provide our customers with the right drive for all areas of application, the HSE swivel motor is available in a total of 6 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Rear exhaust system Vibrationdamping side handle Spindle lock for the replacement of wheel Plastic housing prevents cold hand Side handle can be mounted to right or left Built in governor

Request for a quote

MINEON HANDEL GMBH

Germany

Aluminum Alloy Hinge, POM shaft,Size:65*55mm,Torque strength canbe adjusted by screwdriver,Easy Installation,ROHS compliance.

Request for a quote

MINEON HANDEL GMBH

Germany

Zinc Alloy Hinge,Size:38*40mm and 57.1*50.8mm available,with different standard Torque 1.4/1.8/2.3/3.4N.m.Technical requirements:After 20,000 times lifespan,the torque attenuation deviation is ± 20%

Request for a quoteResults for

Damping - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Electric motors and parts (4)

- Industrial tools (4)

- Hinges (2)

- Internal transport systems (2)

- Reducing gears, hydraulic (2)

- Anti-vibration supports (1)

- Filtering equipment and supplies (1)

- Fuel oil (1)

- Grinding - machine tools (1)

- Milling - machine tools (1)

- Pumps, hydraulic (1)

- Sheet metal and strips, tinplate (1)