- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper processing

Results for

Copper processing - Import export

EHRT MASCHINENBAU GMBH

Germany

All kinds of bending types can be set up with EHRT bending machines. Offset bending, flat bending, bending on edge, torsion bending, closed shapes and U-bends are some examples. The machines offers an outstanding bending accuracy of 0.2°. With the EB40 Professional E, side lengths up to 2000mm can be bent with ease. The tool change on the machine is carried out through a user-friendly plug-in system. This guarantees very fast setup times, yet robust and precise bending tools. The “E” in the name stands for the electric drive of the machine, which enables energy savings of up to 70 %. Due to the absence of a hydraulic unit, which is no longer needed, the machine is significantly more quiet and requires little maintenance. The CNC-controlled side stop is equipped as standard. The machine’s larger tables allow the operator greater degrees of freedom in the bending process, especially with more complex workpieces.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB 40 is distinguished by their extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers’ needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 344 kN. The machine offers an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the EHRT machines. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff's PLC machine control enables machine maintenance and software updates via remote access.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB20 is distinguished by its extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers' needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 222 kN. This machine offer an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the machine. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff’s PLC machine control enables machine maintenance and software updates via remote access.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

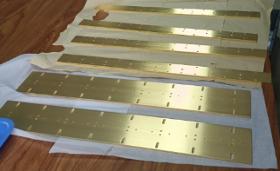

These accessories were made by copper, after CNC machined, then process brushing ,finally do the gold-plating .

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

The smallest electronic components, such as chips or connectors, present special challenges for electroplating coatings. In addition to the conductor pattern construction in the manufacturing of printed circuit boards, copper processes are used for filling blind microvias (blind holes) and metallizing through holes. Good metal distribution is necessary even with unfavorable geometry. The most important application areas are found in the automotive industry, telecommunications, and consumer goods industry, but also in the field of e-mobility.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Cable RTD sensor for clamp-on The Cable RTD sensors of the TRA-W series are constructed differently and adapted to typical operating conditions. The most important differentiating factor of the cable sensors is their process connection, the operating temperature range and the insulation material of the connecting cable. Execution: clamp-on variant Process connection: copper block, Teflon coated, Ø 26 x 18 x 15 mm Temperature range: -50 … +200°C Material: copper / Teflon Sheath - Ø: – Cable material: Teflon IP protection class: 54

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Cable thermometer using RTDs The cable temperature assemblies of the TRA-W series are constructed differently and adapted to typical operating conditions. The most important differentiating factor of the cable assemblies is their process connection, the operating temperature range and the insulation material of the connecting cable. Execution: clamp-on variant Process connection: copper block, 8 x 10 x 40 mm, with Ø 3mm MI-cable Temperature range: -50 … +300°C Material: copper / stainless steel Sheath - Ø: – Cable material: Elexar ( £ 105 °C) IP protection class: 54

Request for a quote

LEONI DRAHT GMBH

Germany

Compacted material terminals made from Cu-ETP1 and Cu-OF1, in bare and tin-plated, nickel-plated and silver-plated upon request, in hard or soft annealed. Cross-section ranging from 1 mm² to 95 mm² depending on welding area. Compact welded terminals of different copper strands can be automated processed. A production of individual parts is possible as well as large-scale production. Resistance welded strands by LEONI are particularly suitable for high-voltage battery connectors, for high power connectors, for switch contacts and for special applications.

Request for a quoteResults for

Copper processing - Import exportNumber of results

10 ProductsCountries

Company type