- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- containers material

Results for

Containers material - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Hygienic design for food, cosmetic and pharmaceutical applications ▪ Easy integration into automated processes due to compact design ▪ Length and weight savings compared to existing pumps ▪ Short cycle times ▪ Non-destructive dosing of solid containing materials with diameter of up to 20 mm ▪ Volumetric dosing and filling, regardless of viscosity ▪ For low to high viscosity materials ▪ Long service life even with abrasive and shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Precise filling with high repeatability ▪ Linear relation between dosing volume and rotational speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ FDA compliant elastomers ▪ Wetted components are autoclavable ▪ Stainless steel ▪ Optional flushing connection for optimum results with CIP ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF SLURRY Following the further development of the Lipp dual seam system and the container material it was possible not only to build silos for bulk materials, but also silos for the storage of liquids, such as liquid manure. Since slurry is also rather more aggressive and can attack concrete or similar vessels, especially over the years, Lipp always offers its system solutions for the storage of slurry in principle in V2A stainless steel (1.4301), when it is clear that the tank will remain open. Possible changes are also taken into account with the customer during the planning process and in case of a future modification of the slurry tank consideration is given to an alternative material (V4A) or the possibility of a subsequent roof construction. Thus, the container retains its flexibility and can later be converted into a fermenter, secondary fermenter or other container.

Request for a quote

SCHAAF TECHNOLOGIE GMBH

Germany

Nice textures & selected flavours presented in attractive shapes The most common extruded products are a wide variety of savoury, direct expanded snacks. Everybody is familiar with products like “Cheese balls”, “Peanut Flips”, “Potato sticks” etc. Raw-materials: Most savoury snacks are made from corn. Sometimes other raw-materials like potato powder, wheat or rice grits are used to impart an identifiable and attractive taste to the base product. Pulses or beans may be added to cater to distinctive local tastes. Similarly materials with high fiber content may be added to increase specific nutritional values. Process: The process can be divided into 3 stages. Pre-extrusion - Single or a homogeneous blend of various raw-materials is moisturised to a pre-determined level with water or water containing materials, prior to extrusion. The moisturisation is done either in batch mode during blending or continuously.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the pharmaceutical industry. Pharmaceutical plants and systems from IFA Technology meet the following requirements as standard: Conformity with the regulations of the US Food and Drug Administration (FDA-compliant) Steel construction made of the material 1.4301 (304) Components in contact with the product, such as containers made of the material 1.4404 (316L) or 1.4435 (316L defined delta ferrite content) Tanks and pipes cooled, heated and/or insulated ("chloride-free") Pipe dimensions according to DIN 11866 Aseptic pipe connections as clamp connections according to DIN 32676 Easy assembly and disassembly

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Containers are available in a wide range of sizes, with diameters of 3 m up to 40 m and volumes up to more than 10,000 m3. WIDE CHOICE OF MATERIALS There is a wide variety of materials to choose from, ranging from steel and galvanised steel through to high alloy stainless steels (e.g. 1.4301 [304] or 1.4571 [316Ti]), according to the requirements of the storage medium in each case. Developed in house, Verinox is a combination of galvanised steel for the outside and stainless steel for the inside of the container. Verinox is an impressive material due to its excellent cost/benefit ratio

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Hopper impact vibrators/bin activators errect bunker walls by periodic oscillations in shock and so the friction between the bulk and bunker wall (caking). They are just for knocking out of forms, for shaking of chutes and downpipes, for better emptying of containers and bulk materials from adhering to solve, for example in filters. The most common activators are unbalanced motors and magnetic vibrators. For special and heavy demands, there are impact vibrators available. Advantages & benefits magnetic impact vibrators excite the bunker walls with aligned linear oscillations. They have no "run out" and respond immediately after switching; the vibrational intensity can be adjusted at the control unit unbalanced motors have a rotating direction of force, they put the bunker wall in uniform, universally effective vibration large vibratory force at small dimensions robust and undemanding Construction In certain cases, a single drive can already act as an activator. If there i

Request for a quote

J.D. GECK GMBH

Germany

Highquality pump dispenser, made in Germany. For all Geck disinfection systems. Also available for wall mounting. Inquire now. Permanently available Made by Geck Produced in Germany Manually operated pump dispenser (handle length approx. 14 cm), with universal holder for 1,000 ml Euro bottles Material housing made of stainless steel and plastic, white Scope of delivery pump dispenser, 1,000 ml disinfectant container, fastening material for wall mounting Optional ,with wall panel including printing of pictograms hand disinfection ,Drip tray with stainless steel holder and plastic tray Contact us at any time via gesundheit@geck.de or visit our website https//www.geck.de/en/healthpreventionsystems.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Minimize false readings or premature degradation Gas-absorbing filters from Porex target specific gases that may cause a sensor to have a false reading or cause premature degradation of the cell itself. Specifically designed for your sensor devices, our gas-absorbing filters: Are effective at capturing a wide range of gases that can be harmful to your sensor, including H 2S, SO 2, HMDS, organics, alcohols and many others. Absorb larger amounts of the problem gas –Compared to competitive materials, POREX® filters absorb more problem gas per unit volume, lasting longer than competitive products. Contain safe materials–POREX filters are constructed with safe-to-use reagents, unlike competitive products with toxic lead-containing components.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dissolving of a wide range of sealants and adhesives such as polyurethane residues, materials containing epoxies Elimination of oily and greasy soiling Removal of bitumen and tar splashes Dissolving of labels and adhesive strips Removal of paints on a PMMA and PU resin basis from metal surfaces Advantages and benefits Good infiltration of adhesive films allows easy removal of the residues from the surface Good washable with water after use Applicable to surfaces of metal, stainless steel, glass, wood, ceramics. Do not apply on sensitive materials such as PVC, PS or on painted surfaces Low effect on the climate and no negative influence on the ozone layer (ozone-depleting potential: ODP = 0) Free of surfactants, halogenated and aromatic solvents

Request for a quote

BÜRKLE GMBH

Germany

The core sampler can be used to take samples of bulk materials which can easily become stuck or settle during sampling due to their particle form. In comparison to standard all-layer samplers for bulk materials, the two-part core sampler has no gap dimensions in which the medium can become stuck while it is being removed. This makes it possible to take a proper sample of powders and granulates through multiple layers, for example glass balls or metal powders. Depending on the size, the stainless steel sampler can be used for a wide range of different containers, for example big bags or small containers. The bulk material sampler takes a representative core sample and is ideal for use in various laboratory and industrial applications.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

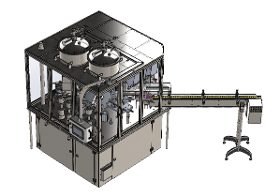

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

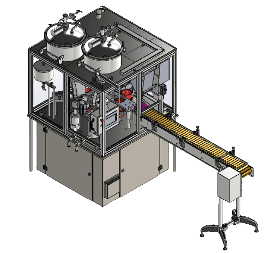

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

We stock high-quality 3D printing filament for private and commercial customers or produce containers, colours or material according to your requirements. Our premium 3D printing filament from EU production offers you the highest quality for demanding projects. The wood filament consists of 100% organic material. The wood filament contains 40% real wood particles. Objects printed with this material have a structure similar to that of chipboard, for example. This wood filament offers a real wood look and feel. The printed parts can then be mechanically finished or painted.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

This Behringer's semi-automatic straight-cutting bandsaws combine the high-cutting output and simple handling which are utilized for economical processing of low piece numbers and one-off cuts. They feature easy handling that are precised in isolating the easy and difficult cuts. These machines are suitable in cutting pipes and all the materials which contain difficult machining properties and they can also provide semi-automatic variants that are recommended for the accurate positioning of a longer cut piece.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

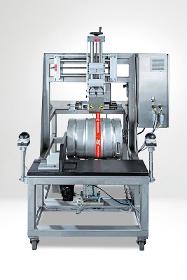

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quote

STRONG MAGNETS GMBH

Germany

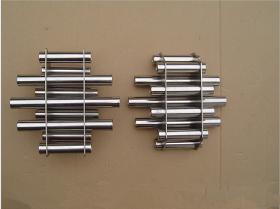

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BAUER GMBH

Germany

can be stacked (3 units) Type BBG -sturdy steel construction made of smooth -steel sheeting Type BBK -sturdy construction made of smooth steel sheeting -with hinged inclined wall for easy loading p.e. with wheelbarrow -reinforced strutting on the rear side of the front flap -secure on both sides to close the front flap Type BBP -sturdy construction made of distortion-proof steel sheeting Accessories -cones for emptying via tilting traverse type BBT galvanized lid, lockable

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

MIXACO MASCHINENBAU

Germany

The MIXACO container mixer Multitool™ is ideal for the careful mixing of temperature-sensitive materials. An innovative mixing concept with new tools and a special process enables mixing without temperature increase. The MIXACO Multitool™ is a container mixer with numerous benefits for internal logistics and production workflows, as it can be seamlessly integrated in work processes. All Benefits at a Glance * Minimal product heating * Optimum homogenization * Adjustable comminution rate * No fusion or adhesion of material * Reduced cleaning time * User-friendly, ergonomically optimized cleaning in preconfigured cleaning position * Material transport in mixing container for greater logistical efficiency * High flexibility * Wide range of tool and motor combinations enable use in many different mixing tasks * Low energy consumption

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Charging station The MIXACO charging station is used for dust free filling of the mixing container with raw materials. In conjunction with a bottom weighing scale or dosing systems, a fully automatic, a semi-automatic or manual charging of the container can be carried out.

Request for a quote

MIXACO MASCHINENBAU

Germany

By means of the moveable container with the mixed material, container with separate trolley, will be positioned in the tumbling mixer. The moveable container will be lifted by a pneumatic stamp. The trolley will be fixed in the tumbling mixer by means of a pneumatically actuated draw-in device. The head of the tumbling mixer formed as a container, fixed on the mixing head with four pneumatically operated clamping jaws including forklift pockets and discharge valve. The lifted container is locked to the tumbling head by means of pneumatically actuated locks. After fixing of the container at the tumbling head a SPS controlled tumbling process starts.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Tabletop soap dispenser in chromeplated brass for counter mounting. Solid body in brass; visible surfaces highgloss chromeplated. Nondrip soap pump with 500 ml soap container in plastics and pressure valve in brass. Designed for standard liquid soaps. Refillable from above by unscrewing the top part. Delivery includes fixing material. Dimensions (with container) 65 x 310 x 130 mm Design height 62 mm Outlet height 37 mm Projection 74 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Tabletop soap dispenser in chromeplated brass for counter mounting. Solid body in brass; visible surfaces highgloss chromeplated. Nondrip soap pump with 500 ml soap container in plastics and pressure valve in brass. Designed for standard liquid soaps. Refillable from above by unscrewing the top part. Delivery includes fixing material. Dimensions (with container) 65 x 456 x 160 mm Design height 208 mm Outlet height 198 mm Projection 111 mm

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Safe storage and transport: Siempelkamp is your container manufacturer for heat-generating and non-heat-generating radioactive materials Wide range of designs for all classes We produce a variety of containers for handling radioactive materials of all classifications. The choice of materials ranges from the use of different casting qualities to granulated concrete and steel. The range of services is completed by the authorization to carry out type tests. For more than 30 prototype types, the required certificates of qualification for the transport and storage of the casks have already been successfully completed in our manufacturing facilities. CASTOR ® casks bodies CASTOR ® casks are used as transport and interim storage containers for fuel elements and high-level radioactive waste.

Request for a quoteResults for

Containers material - Import exportNumber of results

94 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (58)

- Automation - systems and equipment (2)

- Gas fittings (2)

- Tanks, metal (2)

- Towel and soap dispensers (2)

- Labelling machines (1)

- Applicators for adhesives and glues (1)

- Building materials, manufacture - machinery and equipment (1)

- Cement-making - machinery and equipment (1)

- Containers, metal (1)

- Disinfectants, non-medical (1)

- Dosing pumps (1)

- Goods handling systems, continuous (1)

- Magnets (1)

- Models for the building industry (1)

- Oilseed crops (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)

- Plastics - industrial machinery and equipment (1)

- Plastics - machines and material for industry (1)