- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cold steel

Results for

Cold steel - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

We supply the European and international market with cold heading wire / cold extruding steel in sizes ranging from 1.5 mm to 42 mm Production is based at the Hamm and Iserlohn sites, focussing on the following products: Cold heading wire / cold extruding steel Tempering steel Quenched and tempered steels / AFP steels Prehardened steels

Request for a quote

BS STEELWORKS GMBH

Germany

Cold rolled steel sheets are produced by re-rolling process of hot rolled steel sheets in order to provide precise thickness distribution across the coil. The surface roughness of the cold rolled materials is lower compared to hot rolled steels and suitable for painting and coating applications. According to the customers demands, it can be supplied in coil, slitted and cut to length sheet form. Our stock includes cold rolled steel sheet materials produced according to EN 10130, EN 10268, EN 10338, EN 10209 and others.

Request for a quote

BS STEELWORKS GMBH

Germany

Cold rolled steel is low carbon steel produced by a "cold rolling" process and processed at near normal room temperatures. Cold rolled steel offers superior strength and machinability. Cold rolled steel sheets are often used for engineering products where close tolerances, concentricity, surface smoothness and coated surfaces are required.

Request for a quote

ROLLON GMBH

Germany

The Easyslide is a system of cold drawn steel linear rails with induction hardened raceways. The linear guides consists of an external 'C' profile linear rail and incorporated caged ball bearings. Five rail widths: 22, 28, 35, 43 and 63mm The sliders inside the linear rails ensure an exceptionally compact system System high load capacity Optimal operation even when shocks and vibrations are experienced Multiple standard lengths available depending on the linear rail section (up to 2,000mm). Special lengths are available on request The Easyslide product family includes compact size linear rails with caged ball bearings, fitted with one or more sliders per rail, to ensure high load capacity and long life. If more than one slider is used in the SN series, they can slide independently inside their own cages, or simultaneously in a single cage. The SNK series features rails with hardened and ground raceways. Variable slider strokes and lengths can be selected. All Easyslide linear...

Request for a quote

KEBA FASTENINGS

Germany

The KEBAFORM range consists of individually designed engineering solutions resulting in the creation of innovative fasteners. This range fits various requirements, such as holder, stop bolt, distance sleeve, or adjustment element. Multiple phased cold-forming manufacturing processes create a unique and advantageous end product. This know-how and technology allow for a complex fastening element to be formed in up to six blows. PRODUCTION CAPABILITIES • 100% adaptable to any application • Minimization of materials used and inventory costs • Multi-functional use allows for large savings • Simple and efficient assembly • Alternative and replacement of turned parts

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

State-of-the-art technology and extensive knowledge in the processing of steel characterise our location in Bad Salzungen, Germany. For us, performance means a wide range of cold-rolled steels of the highest quality at competitive prices, flexibility and a high degree of readiness to deliver while adhering precisely to the specified chemical and mechanical values. Surface finishing by electrolytic galvanizing and/or subsequent customisation of your goods are possible for us. We offer all our customers spooled materials with volumes of over 200,000 metres of metal strip per spool. This further development means a considerable advantage for our customers. Personnel-intensive set-up times and machine downtimes are avoided.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Cold rolled strip is used in a variety of applications. It meets high demands on forming behaviour, dimensional tolerances and surface finish, which offers our customers decisive advantages! HFP cold rolled strip is ideally suited for all stamping, bending, drawing and deep drawing purposes. From ball bearing housings to roll cutting and punching strips, hose clamps, headlight reflectors, electrical equipment, office supplies and tubes to safety parts of all kinds, a wide variety of components can be manufactured for various industries. DC 01, DC 03, DC 04 according to DIN EN 10139 / mild steel - St 37/ special grades on request Depending on the customer's requirements, we supply treatment states from LG to C690.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Driveline – This is the brand name under which EZM can supply you with drawn bright steel, ground bright steel, peeled bright steel and ground-and-polished bright steel in virtually all cold-formable alloyed and carbon steel grades. Our bright steel is characterised by great dimensional accuracy and high-quality, bright surfaces. Compared to rolled and forged products, cold-drawn bright steel offers the advantage of a greater range of processing options. Of very special importance in this context is a lead-alloyed carbon steel for diesel injection pumps. The unique properties of this EZM speciality offer the perfect answer to such contradictory demands as maximum pressure resistance, on the one hand, and optimum machining properties, on the other. EZM is also a specialist for the processing of antifriction bearing steel/ball bearing steel, as well as alloyed high-grade structural steel. Nozzle body Nozzle body Injector body Injection nozzle DVTD_2V_Section >> Current...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Driveline – This is the brand name under which EZM can supply you with drawn bright steel, ground bright steel, peeled bright steel and ground-and-polished bright steel in virtually all cold-formable alloyed and carbon steel grades. Our bright steel is characterised by great dimensional accuracy and high-quality, bright surfaces. Compared to rolled and forged products, cold-drawn bright steel offers the advantage of a greater range of processing options. Of very special importance in this context is a lead-alloyed carbon steel for diesel injection pumps. The unique properties of this EZM speciality offer the perfect answer to such contradictory demands as maximum pressure resistance, on the one hand, and optimum machining properties, on the other. EZM is also a specialist for the processing of antifriction bearing steel/ball bearing steel, as well as alloyed high-grade structural steel. Nozzle body Nozzle body Injector body Injection nozzle DVTD_2V_Section >> Current...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Driveline – This is the brand name under which EZM can supply you with drawn bright steel, ground bright steel, peeled bright steel and ground-and-polished bright steel in virtually all cold-formable alloyed and carbon steel grades. Our bright steel is characterised by great dimensional accuracy and high-quality, bright surfaces. Compared to rolled and forged products, cold-drawn bright steel offers the advantage of a greater range of processing options. Of very special importance in this context is a lead-alloyed carbon steel for diesel injection pumps. The unique properties of this EZM speciality offer the perfect answer to such contradictory demands as maximum pressure resistance, on the one hand, and optimum machining properties, on the other. EZM is also a specialist for the processing of antifriction bearing steel/ball bearing steel, as well as alloyed high-grade structural steel. Nozzle body Nozzle body Injector body Injection nozzle DVTD_2V_Section >> Current...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Driveline – This is the brand name under which EZM can supply you with drawn bright steel, ground bright steel, peeled bright steel and ground-and-polished bright steel in virtually all cold-formable alloyed and carbon steel grades. Our bright steel is characterised by great dimensional accuracy and high-quality, bright surfaces. Compared to rolled and forged products, cold-drawn bright steel offers the advantage of a greater range of processing options. Of very special importance in this context is a lead-alloyed carbon steel for diesel injection pumps. The unique properties of this EZM speciality offer the perfect answer to such contradictory demands as maximum pressure resistance, on the one hand, and optimum machining properties, on the other. EZM is also a specialist for the processing of antifriction bearing steel/ball bearing steel, as well as alloyed high-grade structural steel. Nozzle body Nozzle body Injector body Injection nozzle DVTD_2V_Section >> Current...

Request for a quote

BS STEELWORKS GMBH

Germany

Hot rolled steel is a type of steel that is formed by the hot rolling process at a temperature above its recrystallization temperature. Steel is easier to form at this elevated temperature. Compared to cold rolled steel, hot rolled steel does not usually require heat treatment after forming. Hot rolled steel usually has more mill scale than cold rolled steel.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BS STEELWORKS GMBH

Germany

Galvanized steel coils are cold rolled sheets coated with Zinc. According to customers need, can be supplied as coil, slitted or cut to length form. Our stock includes generally materials produced according to EN 10346, also other special grades.

Request for a quote

MECHASYS GMBH

Germany

lasercutted sheets bended in hard-tool for mid-range batches, high flexible, batches from 1.000 - 50.000 parts

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SFZ are designed for sandwich plate mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for sandwich plate mounting ▪ Available as left or right version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 30 l/min / 8 US GPM Materials ▪ Filter head: Free Cutting Steel ▪ Filter bowl: Cold Drawn Steel Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Performance The patented STAUFF Form tube forming system is without doubt one of the most high-performing solutions currently available on the market for connecting metric sized tubes. Apart from its simplicity, it also provides a maximum level of safety, reliability and reproducibility. STAUFF Form has been designed as standard for seamless cold-drawn precision steel tubes as well as stainless steel tubes with dimensions between 6 x 1.5 mm and 42 x 4 mm in the Light Series and between 6 x 1.5 mm and 38 x 6 mm in the Heavy Series. Parameters for alternative materials (copper, brass, CuNiFe, Tungum etc.) can be added by the manufacturer, if required. System Design and Components The system is based on standard parts and consists of only four key components: The STAUFF Form Ring with an integrated and thus undetachable elastomeric sealing is slid onto the tube end, which has previously been mechanically contoured. This creates a positive-locking connection that provides a...

Request for a quote

ALPHA LASER GMBH

Germany

The AL-ROCK is a laser hardening system for surface hardening with a self-propelled caterpillar track. The laser can be brought directly to the workpiece. Time-consuming removal of the components to be hardened can often be avoided. The robot arm easily reaches the hard-to-reach places on the workpiece. All common metals can be hardened, e.g. Quenched and tempered steels, cold work steels and cast steel or gray cast iron. The material must have at least 80% pearlite. The degrees of hardness that can be achieved are identical to those of conventional hardening processes. In free 3D movements, the laser beam precisely follows even the most demanding three-dimensional workpiece contours, for example on tracks along closing edges. Pimples, scar structures. Simple points are also not a problem. Only the free access of the laser beam to the surface to be hardened is required. And the AL-ROCK can do even more - on request, the laser robot can also be used for laser welding.

Request for a quote

ABS SAFETY GMBH

Germany

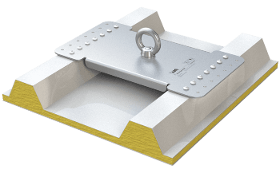

This stainless anchorage point can be installed on a range of different seams and is available in two models. Simply install this anchorage device from above using the stainless steel blind rivets provided. We also supply models for usage as an intermediate bracket or T-junction in a lifeline system. EN 795:2012, A + CEN/TS 16415:2017 Sandwich and trapezoidal sheeting (cold roofs) For steel plating ≥ 0.45 mm; Aluminium ≥ 0.8 mm Distance between the holes: 180-250 mm / 280-333 mm Installation materials included

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

KRONSEDER TROCKENTECHNIK GMBH & CO. KG

Germany

KCT circular vacuum dryer 20 m³ - 60 m³ of stacking space The KCT is characterizedby the advantageous arrangement of its valves. It can easily be connected to existing heating systems and requires but very little heating power. Energy: hot water or electric heating Putting fan on side enhances its performance Measuring point cables on carriage Active cooling in the equalization phase Detection of condensed water Heat and cold registers made of stainless steel Areas of application: Sawmills, lumber and hardwood trade, wood industry

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

ROS ’s roller edges can be used in particular for safe movement of boxes and cartons in flow racks. The rolls are made of high quality thermoplastics (Polypropylene), impact resistant and break-proof. The material is acid and base resistant and does not absorb humidity. The rolls can be easily exchanged. The roller edge with steel axle is designed for easy traveling and low noise material flow. This edge is a solid, variable and economic solution for different logistic ranges of application. Material: — Polished, galvanized profiled steel sheet with round edges, warp resistant — Cold profiled, sendzimir galvanized steel, thickness 1,5 mm Version: — standard rollers or wheel flange rollers Length: — Upon customer’s request (max. 6500 mm)

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

With Conform® components our customers can reduce their procurement and assembly costs: We handle the preceding processes thus enabling slimmer procedures at our customers’ own production facilities. So that we can meet the wide variety of component needs for our customers, we work within a network of certified partners. Some examples of components made to customer specifications: cold-formed parts in steel cold-formed parts in aluminium rubber decoupling elements plastic injection-mouldings stampings metal bending parts non-detachable washers or sealing rings

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Our cold-rolled steel strip is mainly used where particularly high requirements have to be fulfilled: -Quality - Dimension tolerances - Mechanical technological properties - Structural compositions - High-quality surfaces As a long-standing partner of the automotive industry we have for decades provided a considerable amount of our cold-rolled steel strip to renowned international automotive manufacturers and their sub-suppliers. There our material is reshaped using punching, bending, drawing and deep-drawing processes. Another important sector of our clients are renowned manufacturers of safety components, electrical equipment, pipes, profiles, pressure vessels, nuclear plants and manufacturers of a wide variety of other industrial products. They all appreciate our comprehensive selection and combination of technical processes and working materials. We support our clients’ product development. With efficient manufacturing processes, the continuous further development of our technologies, broad range of services and comprehensive consulting expertise.

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

With our own plant at Hagen we finish the basic material for our clients. Electrolytically galvanized in matt or glossy finish and, if required, subsequently phosphated and/or chemically passivated. In addition we can chemically phosphate in accordance with the bonding process. The technological properties of the carrying strip are completely retained during this process. Hence the primary material and the surface finishing produce a high-quality material, which you can easily process and use for many purposes. Details of the properties: - High corrosion-resistance - Best painting capabilities - Decorative appearance - Uniform, homogenous layer thicknesses (1-15 my / side) - Low reject rates - No longer high unit finishing costs - Avoidance of environmental problems - Good deep-drawing behaviour

Results for

Cold steel - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Cold rolled steel strips (7)

- Wires and cables, steel (4)

- Steel (1)

- Bending - steels and metals (1)

- Bending machine tools (1)

- Forming - steels and metals (1)

- Goods handling systems, continuous (1)

- Hand tools, non-power (1)

- Heat treatment of steels and metals (1)

- Internal transport systems (1)

- Laser - cutting and welding machines (1)

- Mechanical transmission - components (1)

- Nuts and bolts, custom-made (1)

- SMALL METAL PARTS (1)