- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change systems

Results for

Change systems - Import export

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS.PSC offers maximum stability and rigidity coupled with maximum flexibility. Significantly reduce your setup and changeover times while maintaining high mold flexibility. he EWS.PSC program includes a wide range of standard tools with PSC shank for milling spindles as well as tool systems with PSC spindle for lathes. Furthermore, tool holders with plate seat are available. The interface allows you to reduce the time spent measuring, setting up and changing tools. In addition, improved machine utilization can be achieved.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

SAMSYS GMBH

Germany

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 – it’s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased. Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system. The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 260 bar = 400 KN Stroke = max. 80mm adjustable via limiter switch 20 Double strokes / min. Max. daylight = 300 mm Working range: ram to back wall = 200 mm Table dimension: 600 x 400 mm Quick change tool system

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 260 bar = 200 KN Stroke = max. 80mm adjustable via limiter switch 20 Double strokes / min. Max. daylight = 300 mm Working range: ram to back wall = 200 mm Table dimension: 600 x 400 mm Quick change tool system

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 200 bar = 160 KN Stroke = max. 80 mm adjustable via limiter switch 14 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Table dimension: 280 x 200 mm

Request for a quote

BIZERBA SE & CO. KG

Germany

High-tech meeting the highest demands. More customer benefits for future requirements Intelligent Weigh Price goods labelling system from Bizerba. Unique in it's class and recognised as the worlds leading experts in weigh price labelling systems for the food industry. High Speed High IP protection with intuitive BRAIN software. Easy to operate and maintain incorporating the Bizerba quick belt change system that does not require tools. The flexible system will easily incorporate into existing production lines seamlessly. Additionally the system will talk to existing software packages with our _Connect BRAIN software module. The Intelligent Weigh Price goods labelling system weighs, labels rejects inferior weights automatically. Depending on the speed requirements and the lines the Weigh Price Goods Labelling System can achieve up wards of 170 packages per minute. High-tech meeting the highest demands. More customer benefits for future requirements. The intelligent labelling...

Request for a quote

BIZERBA SE & CO. KG

Germany

Compact meat and bone saw for sales counter or preparation room The FK 23 Meat and bone saw is made entirely from stainless steel and with the very best quality construction all round. Ergonomic and effective cutting and portioning of fresh and frozen foods. Multiple saw blades are available all with the Bizerba quick, easy safe blade change system. Suitable for left and right handed operations. Even the saw wheel can be removed, cleaned and replaced without the need for tools. The total protection type is IP55. Additionally this unit can be supplied with a larger work bench and alternative special saw blades depending on your personal requirements. If you are a butchers looking to cut heavy and even frozen carcasses then this will be the ideal solution. Alternatively the system will also cut delicate fish products or matured beef products gently with ease. Easily cut products safely without effort 250 millimetres in height and up to 190 millimetres in width. If you require a...

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Get the most out of your slicer blades! With the weSHARP 7000 sharpening center, you can quickly and easily get back the ideal slicing properties of your blades, even after intensive use in the slicer. The weSHARP 7000 is suitable for the refurbishment of all Weber Durablade Performance, involute and circular blades, and guarantees a precise and reproducible sharpening result with minimal material loss of the cutting edge. Thanks to program recognition and data storage, the sharpening process can be completed in the shortest possible time, and the use of tool-free fast-change systems also ensures that setup times are kept to a minimum. Advantages Simple operation with RFID technology Sharpening of all Durablade circular and involute blades Precise and reproducible sharpening result Precise sharpening process thanks to servo drive Convenient handling via touchscreen

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 50 KN Stroke = 37 mm Max. daylight = 200 mm Working range: ram to back wall = 110 mm Swiveling table to use tools to manufacture holes for sash bars

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 90 KN Stroke = 40 mm 25 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Working height 950 mm

Request for a quote

MAHLO GMBH & CO. KG

Germany

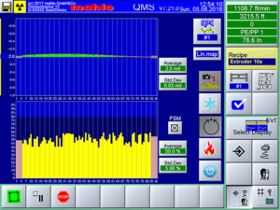

Automatic control of thermal diebolts of extrusion dies The DieControl APC Pro automatically controls thermal bolts of extrusion dies according to the earlier measured cross-section profile of the material. This results in uniformly thick films, sheets or coatings even with fluctuations in the feed, material change or when starting the system. The automatic control and the extrusion close to the set point also achieve considerable material savings and quality improvement.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FESSMANN GMBH UND CO KG

Germany

Our FESSMANN online support will help you optimise the system parameters using stateoftheart control technology and network technology. We offer detailed problem analyses, problem solutions and system optimisations on the phone or with online connection. The first fifteen minutes of FESSMANN online support are always free of charge. Updates and changes to system parameters are possible by remote maintenance – and if you wish, you can be live on site for it! Service deployments are often rendered unnecessary by this. If they are necessary after all, our experts will pick the right spare parts for you right away, enabling our very well trained and experienced service engineers to install them immediately. This makes service quick and efficient. You can increase system availability and thus improve your productivity.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The FireBird® Gold Edition sets blind rivet nuts up to M8 all materials with 20.000N traction power • Drill-on of the blind rivet nut with reduced • torque and automatic switch-off • Triggering the setting process clearly • separated from the drill-on action • Automatic drill-out function after the end of the setting process • Drill-off with high torque • Sturdy, compact and shockproof tool housing Ergonomics • Fatigue-free working through well balance weight repartition and ergonomic grip • Easy stroke adjustment with Li-Ionen-Energy • High energy yield due to high voltage • Low weight allows for extremely easy and fast operation • Extremely low self discharge • New battery shape allow the tool to be stored standing on its battery • Constant setting speed • Automatic switchover from setting to drilling • Fast and simple change system for threaded mandrels More details on delivery limits will be answered in a specific enquiry (details are only exemplary)!

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• Drill-on of the blind rivet nut with reduced torque and automatic switch-off • Triggering the setting process clearly separated from the drill-on action • Automatic drill-out function after the end of the setting process • Drill-off with high torque • Sturdy, compact and shockproof tool housing Ergonomics • Fatigue-free working through well balanced weight repartition and ergonomic grip • Easy stroke adjustment With Li-Ion energy • Battery with 2.0 Ah (standard) or power battery with 4.0 Ah as special accessory • No memory-effect • High energy yield due to high voltage • Low weight allows for extremely easy and fast operation • Extremely low self discharge • New battery shape allow the tool to be stored standing on its battery • Simple and safe drilling of the blind rivet nuts • Constant setting speed • Automatic switchover from setting to drilling • Fast and simple change system for threaded mandrels

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

KAMAT GMBH & CO. KG

Germany

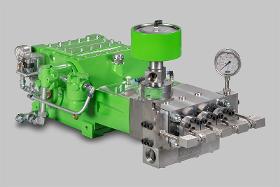

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Powder systems with robots can be effectively used even for small batches. In addition to the classic method of powder coating using manual spray guns or masts, the demand for robot systems has risen sharply. Rippert offers the entire spectrum here too. Both powder-coating systems with robots and wet painting systems are supplied with intelligent software solutions. This also allows the economical processing of small lot sizes. Automatable high-speed paint changing systems have also been available for some time. Rippert plays a leading role in automated powder-coating systems with industrial robots.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

ABS SAFETY GMBH

Germany

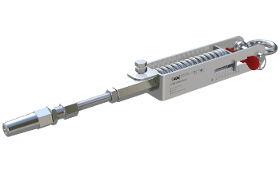

This stainless steel lifeline end attachment - specially designed for our ABS-Lock SYS (8 and 6 mm) lifeline systems - can be used to compensate deviations in temperature. This tensioning element is made of 316 steel, is equipped with a spring bias and has been awarded national technical approval by the German Institute for Construction Technology (DIBt). General national technical approval (German: "abZ"): Z-14.9-786 EN 795:2012, C & CEN/TS 16415:2013 Spring bias with an easily-readable gauge Inspection window allows monitoring of the cable clamping mechanism Counters slack caused by temperature changes One-piece clamping system Easily installed Manufactured completely from robust V4A stainless steel

Request for a quote

ALPHA LASER GMBH

Germany

Design and geometry freedom withh high material yield. With its unique cartridge concept, the 3D metal printer AL3D-METAL offers safe powder management and quick powder change. The new system AL3D-METAL makes it easy to get started in additive manufacturing. The processor does not come into contact with the powder. Also ideal for schools and universities. The intelligent cartridge knows which powder it is filled with and provides the right process parameters. However, if the processor likes to experiment, he has full control over the parameters. Its floor print is only 60 x 60 cm

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping.

Request for a quoteResults for

Change systems - Import exportNumber of results

84 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (21)

- Packing and packaging - machinery and equipment (5)

- Milling - machine tools (4)

- Robotics (3)

- Bending machine tools (2)

- Portable power tools (2)

- Monitoring and control equipment (1)

- Adjustment - machine tools (1)

- Assembly robots (1)

- Butchery - machinery and equipment (1)

- Conveyor systems (1)

- Electric motors and parts (1)

- Electronics - ships (1)

- Energy and raw materials - services to industry (1)

- Food Industry - Machines & Equipment (1)

- Food Processing (1)

- Forming - steels and metals (1)

- Labelling machines (1)

- Laser - cutting and welding machines (1)

- Machine tools - metal machining (1)