- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cabling machines

Results for

Cabling machines - Import export

IGUS® GMBH

Germany

-For medium duty use -Minor oil influence -More suitable for indoor applications, but also for outdoor use at temperatures > 5 °C -Unsupported travel distances and up to 20 m for gliding applications -Bus connection cable for machining units/machine tools, handling, indoor cranes

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Two accumulation places für high speed Low maintenance Low wear Very quiet operation Also without accumulation areas possible Upstream and downstream interlocks Settings by intuitive operating terminal In conveying direction left or either right Machine movable Power cable, length 3m OPTIONAL: One pop-out roller on entry side PLC control Table height steplessly adjustable Many specific options available, easily configurable Fully electrical system, no pneumatic connection required

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 451

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This machine is not only able to crimp the biggest hoses ever for a UNIFLEX machine, it is also the most compact machine for mobile work in UNIFLEX history. The HMC 12-2000 is the most solidly built C-crimper of the 2000 ton category due to its integrated power booster for high crimping forces. After a long period of research and development in the field of FEM, this machine outshines all others of its category. UNIFLEX defines new crimping techniques and focuses on not only the highest quality and user friendliness but also advanced materials. The strongest C-Crimper for hoses worldwide •C-form crimper with 2000t effective pressforce with UNIFLEX greaseless technology •C-form crimping tool, open on the side, with an 355mm opening - no limit for flanges •Max. crimping range 380mm •For up to 3“ hydraulic / offshore / tubular & 12“ industry hoses •Robust construction for heavy duty •Ideal for special application with its high crimping force

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Cable trunking for footfall loading in machining centres PFLITSCH Automobile-Trunking complies with the works standard for many automotive manufacturers and serves as walkable floor trunking in many automated manufacturing lines and robotic production plants, allowing loads of up to 1,200 N and using antislip channelled sheet covering (slip-resistance rating R10). With seven cross sections from 100 mm to 600 mm wide, standard base perforations and universal separating walls, this robust trunking can be placed and combined with other PFLITSCH trunking systems to customer requirements. Your advantages: Walkable floor trunking with high footfall load High strength, wide support spacing Channelled sheet for antislip safety Can be combined with other trunking systems

Request for a quote

U.I. LAPP GMBH

Germany

This is the brand of choice if you want fast, safe and forward-thinking solutions for tranferring data. The range includes data cables for all electronic applications, from tiny cables in coffee machines to those transferring huge amounts of data in supercomputers. Properties: — Robust, durable and reliable. — Suitable for a wide range of uses, including under chemical and mechanical stress, in humid conditions and in various temperatures. — Suitable for fixed connection or energy supply chains. — Also halogen-free and available with international licences.

Request for a quote

JACOB GMBH

Germany

The Cable Entry Plate KADP is used to insert and seal cables in enclosures, machines and control cabinets. It provides a high flexibility for varios applications. KADP is perfect in tight spaces, as several cables can be inserted into the plate. Due to the ideal placement of the close-fitting insertion points, a high packing density with a protection grade of IP66 is achieved. The installation of the KADP into the enclosure is time-saving, by simply snapping the plate in with a single click. The cables are simply plugged in and the job is done. The "pushout" membrane re-seales almost by itself after removing the cable.

Request for a quote

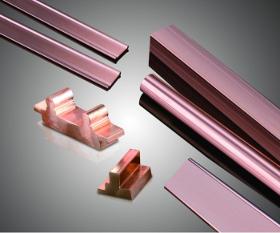

JINTIAN COPPER

Germany

Main products: TMY copper, T2 / TU2 copper rods, profiled bars, electrical round copper billets Product characteristics: High copper content, low oxygen content, compact structure, uniformity, low electrical resistivity, high electrical conductivity, precise size, excellent mechanical properties; can be customized according to demand Applications: High and low voltage electrical appliances, power electronics, power transmission and transformation, automotive industry, molds, communication technology, cables, machining, metallurgical chemicals, construction industry Production capacity: 100,000 tons Honorary titles: Zhejiang Famous Brand Product

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Produce your air cushions automatically to avoid unnecessary waiting times. Once the stock level is reached, your AirWave1 or AirWave2 automatically stops the production using the level sensor. The machine automatically starts again as soon as cushions are removed from the container. The level sensor with infrared light barrier has a sensor range up to 400 mm. Fits the AirWave1 and AirWave2 air cushion machine. Cable length: 1.35 meters

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

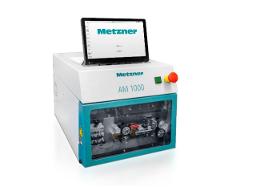

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials. Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The EM 600 can integrate up to six successive process tools in one single station. After insertion, the cable remains in a fixed position while the tools move towards the cable to provide optimum protection for the HV cable wires. The total cycle time of an EM 600 station is approx. 35 seconds for all operations of this station, with a total capacity of approx. 400,000 cable ends per year.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

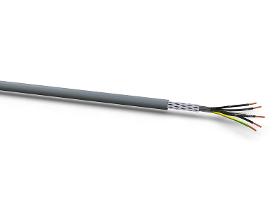

GLOBALFLEX®-CY-control cables are used in tool-machines conveyor belts, production line in machinery production, in air-conditioning and in steel production for low loss data and signal transmission. They are used for installing in dry, moist and wet rooms, especially under the terms of industrial environment. Outdoor use only with UV-protection allowing for temperature range. GLOBALFLEX®-CY-control cables are suitable for medium mechanical stresses with free movement without tensile stress or forced movements. The high level of screening ensures a high degree of interference protection. the screening density assures disturbance free transmission of all signals and impulses. The product corresponds to the directive 2014/35/EU (low voltage directive).

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

GLOBALFLEX®-CY-control cables are used in tool-machines conveyor belts, production line in machinery production, in air-conditioning and in steel production for low loss data and signal transmission. They are used for installing in dry, moist and wet rooms, especially under the terms of industrial environment. Outdoor use only with UV-protection allowing for temperature range. GLOBALFLEX®-CY-control cables are suitable for medium mechanical stresses with free movement without tensile stress or forced movements. The high level of screening ensures a high degree of interference protection. the screening density assures disturbance free transmission of all signals and impulses. The product corresponds to the directive 2014/35/EU (low voltage directive).

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

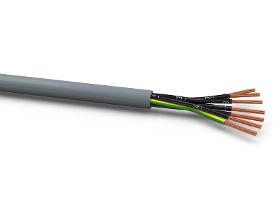

PVC-Control cables are used in tool-machines, conveyor belts, production lines in machinery production, in air-conditioning and in steel production. They are used for installing in dry, moist and wet rooms, specially under the terms of industrial environment. Outdoor use only with UV-protection allowing for temperature range. GLOBALFLEX®-control cables are suitable for medium mechanical stresses with free movement without tensile stress or forced movements.

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

Used as control cables and supply lines in machine engineering, plant engineering, enameling lines, power stations, air conditioning, cool systems, office machines and data precessing systems. Mainly suitable for dry, damp or wet interiors, especially in industrial environments at medium mechanical stress. Outdoor use with UV-protection only and in observance of the temperature ranges. Suitable for free, not continously returning movement without tensile stress or compulsory guidance as well as for fixed laying. GLOBALFLEX®-COLD is mainly used for cold-flexible applications due to cold-resistance up to -30°C.

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

Used as control cables and suply lines in machine engineering, plant engineering, enameling lines, power stations, air conditioning, cooling systems, office machines and data precessing systems. Mainly suitable for dry, damp or wet interiors, especially in industrial environments at medium mechanical stress. Outdoor use with UV protection only and in observance of the temperature ranges.Suitable for free, not continously returning movement without tensile stress or compulsory guidance as well as for fixed laying. GLOBALFLEX®-JZ/OZ 0,6/1kV is UV-resistant and mainly used for applications in southern European countries, Arabic countries and eastern European contries.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

With VIBRONET Signalmaster, up to 162 measuring points can be installed and entire production areas can be included in the monitoring. The distance between the basic unit and the sensor does not play a decisive role, because the wiring concept used reduces installation costs to a minimum. VIBRONET Signalmaster is therefore one of the most efficient and costeffective monitoring systems for large machinery and extensive plants with productioncritical units. Vibration, temperature, RPM and other process parameters can be integrated into a monitoring network that covers whole plant sections.The robust cabling installation guarantees reliable machine monitoring even in harsh environments such as cement plants, openpit and underground mining or refineries. VIBRONET Signalmaster is easily expandable. The data recorded can be analyzed in OMNITREND CENTER, the universal software platform for PRUFTECHNIK's Condition Monitoring systems.

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: ■ Ideal cutting results ■ Improved sample quality through an exact and reproducible sample thickness ■ Suitable for a wide variety of materials ■ Robust and durable blade with double wear time (2-sided usable) ■ Exact adjustment of the rotating speed ■ The influence of the operator is minimized by the predefined blade feed ■ Fine, manual dosing of the progessive feed Area of application: ■ Sample preparation according to IEC EN 60811 ■ Cutting device for samples with an outer diameter up to 65 mm (2.56 Inch) ■ Optimal preparation of samples before the precise analysis on the offline cable meaurement device ■ Use of the O-Ring Cutter VC is essential for your Quality Management ■ Precise and repeatable measuring results possible with conistent cut samples ■ The VC65 supplements the measurement devices of the VCP series with even and consistently cut samples ■ Compact and light device for laboratories and in the production

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: Save up to ⅔ measuring uncertainty with well prepared samples ■ Quick and efficient cut ■ Thin, evenly and parallel cut samples with a smooth surface ■ Is a ideal complement to ORC65 and ORC150 ■ First ORC device which cuts sectors with ease ■ LED light to illuminate the cutting process Area of application: ■ Sample preparation according to IEC 60811 ■ Quick and efficient cut of hard materials (PE, XLPE) with an outer diameter up to max. 80 mm (3.15“) ■ Optimal cable preparation device for measurements with offline cable measurement devices ■ Use of the Cable O-Ring Cutter is essential for your Quality Management ■ Compact and light device to easily use in laboratories and production halls

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Save up to ⅔ measuring uncertainty with well prepared samples ■ Easy and fast operation ■ Robust, compact device out of stainless steel - no corrosion ■ 4 different adapters to stabilise the samples (on request more adapters of different sizes available - Product No.: 402.0007.13) Area of application: ■ Sample preparation according to IEC 60811 ■ Sample cutting device for cutting very small samples up to 3.5 mm (0.14“) outer diameterdepending on material and wall thickness ■ Optimal cable preparation device for measurements with offline cable measurement devices ■ Use of the Cable O-Ring Cutter is essential for your Quality Management ■ Compact and light device to easily use in laboratories and production halls

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: ■ Quick and efficient cut ■ Thin, evenly and parallel cut samples with a smooth surface ■ Very robust device made of aluminium and stainless steel - no corrosion ■ By using special chuck jaws it is even possible to cut larger samples with an outer diameter up to 200 mm (7.87“) ■ Light to illuminate the cutting process ■ Precise and repeatable measuring results possiblewith the cut samples Area of application: ■ Sample preparation according to IEC 60811 ■ Optimal cable preparation device for measurements with offline cable measurement devices ■ Cut samples complement the cable measuring devices from the VisioCablePro® series ■ Use of the Cable O-Ring Cutters is essential for your Quality Management ■ Easy use in laboratories and production halls

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: ■ Save up to ⅔ measuring uncertainty with well prepared samples ■ Very robust device for quick and efficient cutting of flat cables ■ Exact adjustment of the sample thickness (depending on material) ■ Thin, evenly and parallel cut samples with a smooth surface (especially the very small and many cores require a very thin cut to avoid shadows) ■ Precise and repeatable measuring results due to reproducible samples Area of application: ■ Sample preparation according to IEC 60811 ■ Cutting device for flat cable samples up to a width of max. 75 mm (2.95“) and a height of max. 8mm (0.31“) ■ Optimal cable preparation device for measurements with offline cable measurement devices ■ Use of the FCC75 is essential for your Quality Management ■ Compact and light device to easily use in laboratories and production halls

Request for a quoteResults for

Cabling machines - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (9)

- Copper wires and cables (5)

- Cutting, plastics - machinery (5)

- Cables, high-voltage (2)

- Silicones (2)

- Cable ducts (1)

- Copper and copper alloys (1)

- ELECTRIC EQUIPMENT (1)

- Electric cables (1)

- Industrial cabling (1)

- Monitoring and control equipment (1)

- Presses, hydraulic (1)

- Switching systems (1)