- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearing elements

Results for

Bearing elements - Import export

FRANKE GMBH

Germany

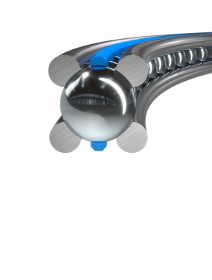

Franke bearing elements of type LEL are suitable for high demands on running characteristics and accuracy. Due to the hardened and CNC-ground raceway as well as the ideal geometrical adaptation of ball and raceway radius, they have outstanding bearing characteristics. Bearing elements of type LEL allow the greatest possible freedom of bearing design. The mounting space is between 5.9 mm and 20.9 mm. For special requirements, raceway thicknesses up to 20 mm and ball sizes up to 50 mm are possible.

Request for a quote

FRANKE GMBH

Germany

Franke bearing elements type LER are suitable for medium rotational speeds and accuracies. They convince by smooth running, high dynamics and compact installation space. Due to the straight contact surfaces, they can be easily integrated into the surrounding design and have a high rigidity. The low price makes the bearing element of type LER an economical solution. LER are generally mounted without clearance. The preload can be individually adjusted according to the requirements.

Request for a quote

IGUS® GMBH

Germany

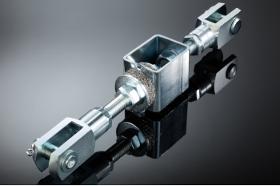

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

IGUS® GMBH

Germany

igubal® pillow block bearing, mm/inch Dimensional series K in mm and inch dimensions igubal® pillow block bearing, mm/inch igubal® pillow block bearing KSTM-GT Dimensional series K, large dimensions igubal® pillow block bearing KSTM-GT igubal® pillow block bearing ESTM Dimensional series E igubal® pillow block bearing ESTM igubal® pillow block bearing ESTM-SL Dimensional series E, narrow dimensions igubal® pillow block bearing ESTM-SL igubal® pillow block bearing AD-01-ESTM Adapter for pillow block bearings of dimensional series E igubal® pillow block bearing AD-01-ESTM igubal®- pillow block bearing ESTM-GT..-GT Dimensional series E with split housing and split ball igubal®- pillow block bearing ESTM-GT..-GT igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT with cylindrical bore igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT150 igubal® ESTM-GT150 - Large pillow block bearing with gliding layer for diameters up to 150 mm. igubal® pillow block bearing ESTM-GT150 Maintenance-free, self lubricating High stiffening High fatigue strength in varying loads Compensation for alignment errors Compensation of edge loads Corrossion-resistant Chemical resistant High dampening qualities Suitable for rotary, oscillating and linear movements Very low weight High radial loads Usable in media Space saving Easy to fit Life time predictable Maintenance- and lubrication-free igubal® pillow block bearings are very easy-to-mount bearing elements which compensate for errors and prevent misalignments. Application area igubal® pillow block bearings ideally compensate for shaft misalignments, tilts and bends through their spherical adjustability. Main application areas are wherein such effects should not hinder special designs. igubal® pillow block bearing - Applications Tolerances Maintenance-free igubal® pillow block bearings have a tolerance in the inner diameter, according to E10. The shaft should have a tolerance between h6 and h9. The bearing clearance compensates for bearing expansions during heating. Installation igubal® pillow block bearings are designed to be fastened with 2 screws. A precise alignment of the bearing housing is not required as the spherical bearing automatically compensates for error. Delivery program igubal® pillow block bearings are available in the dimensional series K and E for shaft diameters from 5 to 50 mm. The dimensional series K is also available in inch dimensions. Please ask us for other dimensions. When to use it? When chemical resistance is required When a low-cost alternative is desired When dirt-resistant bearings are needed When misalignments should be compensated When fully split components are needed When not to use? When temperatures above +80°C prevail When an integrated collar is required When dimensions over 50 mm are needed When rotation speeds in excess of 0,5 m/s should be implemented igubal® pillow block bearing, mm/inch Dimensional series K in mm and inch dimensions igubal® pillow block bearing, mm/inch igubal® pillow block bearing KSTM-GT Dimensional series K, large dimensions igubal® pillow block bearing KSTM-GT igubal® pillow block bearing ESTM Dimensional series E igubal® pillow block bearing ESTM igubal® pillow block bearing ESTM-SL Dimensional series E, narrow dimensions igubal® pillow block bearing ESTM-SL igubal® pillow block bearing AD-01-ESTM Adapter for pillow block bearings of dimensional series E igubal® pillow block bearing AD-01-ESTM igubal®- pillow block bearing ESTM-GT..-GT Dimensional series E with split housing and split ball igubal®- pillow block bearing ESTM-GT..-GT igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT with cylindrical bore igubal® pillow block bearing ESTM-GT igubal® pillow block bearing ESTM-GT150 igubal® ESTM-GT150 - Large pillow block bearing with gliding layer for diameters up to 150 mm. igubal® pillow block bearing ESTM-GT150

Request for a quote

FRANKE GMBH

Germany

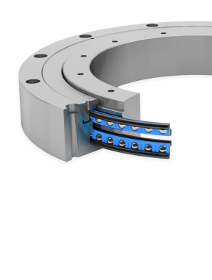

Franke bearing elements type LEW are suitable for medium rotational speeds and accuracies. They convince by smooth running even under tilt moment loads, high rigidity and compact installation space. The crosswise arranged rollers can support high loads from all directions. Bearing elements of model LEW are insensitive to shock and vibration. They offer the greatest possible flexibility in terms of preload, running characteristics and diameter ranges.

Request for a quote

FRANKE GMBH

Germany

Franke slim bearings of the type LSA convince by their smooth running, extremely compact installation space, simple mounting and favourable price. Slim bearings of type LSA consist of an inner and outer race with hardened and profiled raceways and a plastic cage with retained balls. The rolling elements rest against the raceways at two points each, thus maintaining the 4-point system. The raceways are split and can therefore be changed elastically in diameter for installation.

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Vibration dampers of the series GAB are especially used to stabilize your pipe system. You can use these elements to absorb thermal expansion of the pipes, too. These elements are often used in the field of plant engineering. Depending on the chosen series you are able to couple your system with this elements by a welding profile or a fork head. RG+ offers these suspensions in the following designs: GAB-( )-2 with one fork head on each site GAB-( )-5 with one fork head on one site and a welding profile on the other

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Fastening elements, bearings and add-on elements for pneumatic cylinders according to ISO 6432 and ISO 15552.

Request for a quote

FRANKE GMBH

Germany

Franke bearing asseblies type LVD are ready to install bearing assemblies with external gear, steel housing rings and integrated bearing elements. Franke bearing assemblies type LVD are suitable for medium rotational speeds and accuracies. They can be supplied at short notice, in some cases even from stock. Designed as 4-point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. The bearing elements are sealed on both sides and adjusted to preload.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Pneumatic cylinders according to the norm, standard or special design, completely configured ready for installation and pre-assembled with add-on parts, bearing elements, compressed air connections, position sensors or control valves according to customer specifications.

Request for a quote

FRANKE GMBH

Germany

In the case of larger bearings and bearing elements, adjustment of the rotational resistance is simplified by using washers between the split inner or outer rings. The washers are made of stainless steel. For the coordination it is advisable to provide a theoretical starting gap of 0.5 mm in the design.

Request for a quote

FRANKE GMBH

Germany

For our bearing assemblies and linear systems, we use high-quality lubricants as standard that are suitable for most applications. Special operating conditions require special lubricants. Standard and special greases are available in the respective container sizes from us as accessories. They can be used when our bearing elements are used for the first time or for relubricating slewing rings.

Request for a quote

FRANKE GMBH

Germany

The bearing assemblies are equipped with the S10 boot seal as standard. Temperature: –30 ° C to +80 ° C (NBR). Max. Peripheral speed: 5 m / s. For the sealing of the construction (e.g. when using a bearing element) the seal can be ordered by the meter. The joint is then glued with Loctite 401® adhesive. Special seals are available on request. Franke offers Viton seals for high temperatures or aggressive media.

Request for a quote

FRANKE GMBH

Germany

Franke bearing assemblies type LVE are bearing assemblies with toothed belt gearing, aluminium housing rings and integrated bearing elements. Franke bearing assemblies type LVE are suitable for medium rotational speeds and accuracies. They convince by their low weight and are available at short notice, in some cases even from stock. Designed as 4-point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. The bearing assemblies are sealed on both sides and adjusted to preload.

Request for a quote

FRANKE GMBH

Germany

Franke Bearing Assemblies Type LVA are ready-to-install bearing assemblies with steel housing rings and integrated bearing element. They are suitable for medium rotational speeds and accuracies. They are available at short notice, some of them even from stock. Designed as 4 point bearings, they can support equally high loads from all directions and are insensitive to shocks and vibrations. Type LVA bearing assemblies are sealed on both sides and adjusted with preload.

Request for a quote

FRANKE GMBH

Germany

Franke bearing asseblies type LVG are bearing assemblies made of aluminum, designed as double row angular contact roller bearings with integrated bearing elements. LVG bearing assemblies are suitable for the highest load ratings. They convince by high rigidity, low rotational resistance and low weight. Designed as roller bearings, they can support high loads from all directions and are insensitive to shocks and vibrations. Franke LVG are sealed on both sides and are set with preload. By using aluminum, Franke beaing assemblies type LVG are 60% lighter than comparable steel bearings.

Request for a quote

FRANKE GMBH

Germany

Franke bearing asseblies type LVC are bearing assemblies made of steel, designed as double row angular contact ball bearings with integrated bearing elements. Franke LVC are suitable for highest circumferential speeds. They convince by very high dynamics and a very low rotational resistance. The double row angular contact ball bearings in a 4-point arrangement are preloaded. They are insensitive to shocks and vibrations. The low rotational resistance and the minimal breakaway torque reduce the required drive power. Due to the low coefficients of friction, Type LVC bearing assemblies operate almost maintenance-free and achieve a long service life.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OHRA-REGALANLAGEN GMBH

Germany

Cantilever racking systems are highly load-bearing storage systems intended for storage of long and/or bulky storage materials. Such goods include timber, wooden boards, metal sheets, sections, beams or steel elements, building materials but also scrap cars and all kinds of heavy loads. Cantilever racking by OHRA is distinguished from standard racks using solid steel sections for all load-bearing elements. Thanks to this slim construction of our racks a high storage capacity can be achieved across a small floor space. There are specific types of cantilever racks for every product and for every industry. They differ based on requirements, height, useable depth, load-bearing capacity or section thickness. All cantilever racking are produced individually according to customer requirements; they are equipped with a high-quality powder coat or hot-dip galvanised for outdoor storage.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS slewing rings offer precise rotation technology to reliably connect two or more parts in your application. They are available in a wide variety of designs. As high load-bearing machine elements, they can safely absorb radial, axial and tilting moment loads with one bearing point and thus significantly reduce the effort required for the design of the adjacent construction. Sealed and lubricated, our slewing rings offer long-term performance even under demanding operating conditions. They are used in the fields of mechanical engineering, automation and robotics, among others. We are happy to work with you to develop the right slewing ring for your specific application requirements.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

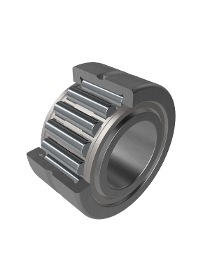

KIS needle roller bearings are ideal for applications that require space-saving rolling bearings with high load carrying capacity. We offer needle roller bearings in both radial and axial designs as well as in combined designs. In bearing technology, cylindrical rolling elements are referred to as needles if the rolling element diameter is ≦ 6 mm and the ratio of rolling element diameter to rolling element length gives a value Dw/lw < 1:3. Radial needle roller bearings are intended exclusively for use as non-locating bearings. The given axial displacement path for bearings with an inner ring allows axial movements between the shaft and the housing. If necessary, wider inner rings are available to allow larger axial displacement paths. Our combined needle bearings are characterised by particularly high precision and efficiency. By integrating both bearings into one unit, combined needle roller bearings are often easier to press in and easier to handle than individual solutions.

Request for a quote

ABS SAFETY GMBH

Germany

This rail guard system has been awarded national technical approval and is based on a lightweight aluminium design. This easy-to-use anchorage device with its integrated glider can be installed on walls, ceilings or roofs. A wide range of angular and curve elements are available to adapt your system to perfectly match your architecture. National technical approval ("abZ"): Z-14.9-807 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, D + CEN/TS 16415:2013 Secures 3 individuals simultaneously (1 individual per glider) High-strength aluminium design, extremely lightweight Simple and quick installation on a roof, wall or ceiling Expands and contracts with heat and cold based on a floating bearing design (straight systems) Rail element: 2.34 m; Optional: Custom lengths available Horizontal and vertical curve elements: Standard 90°; Optional: Custom angle/radius upon request

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 630 - 1600 P The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination. Special properties for the customer’s benefit: Swinging open housing for easy inspection Clean room installation possible Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit Fully automatic, validated CIP-process possible Design virtually free of dead spaces, minimized number of screwed connections in the process housing Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing High flexibility at frequent product changes Quick change of the filter element Bearing designed as exchangeable unit

Request for a quote

MEGATRON ELEKTRONIK GMBH & CO. KG

Germany

The FHx58 family is ideally suited for use in the food industry, pharmaceuticals and offshore applications. Encoders are available in two sensor technologies: Optoelectronic: incremental encoder (FHI58) 3D Hall: absolute encoder (FHB58 & FHS58) The high-class mechanical encoder design is independent of the installed sensor technology. High-quality ball bearings allow shaft loads up to 100 N. The dead-space-free sealing and bearings elements guarantee a wobble free shaft operation and ensures that no impurities can infiltrate. The FHx58 can be cleaned with high pressure and steam jets (IP67/P69k). The stainless steel encoder body which is specially surface-treated in combination with PTFE, TPE sealing elements allow that the FHx58 can be used in applications with high hygienic standards. Precisely it is this design which allows to operate the FHx58 also in salty atmospheres permanently or to clean the encoder with cleaning-fluids containing acids and chemicals.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Lightweight structures in the automobile industry demand savings in materials and weight, while using materials and components with high load capacities. Plastic-moulded bushes take account of this development. They reinforce the plastic, make weak points for load-bearing functional elements and receive the pre-load forces of screw fastenings. The use of aluminium bushes saves even more weight, providing sophisticated solutions when combined with TAPTITE 2000® thread-rolling screws. Conform® bushes indicate high accuracy in length and diameter.

Request for a quoteResults for

Bearing elements - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Bearings, antifriction (15)

- Bearings, ball (15)

- Bearings - ball, needle and roller (13)

- Bearings, needle (2)

- Bearings, roller (2)

- Plain bearings (2)

- Cylinders, pneumatic (1)

- Industrial piping (1)

- Mechanical transmission - components (1)

- Sensors (1)

- Shelving, storage (1)

- Vehicles - mechanical components and parts (1)