- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnet manufacturer

Results for

Magnet manufacturer - Import export

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned flat pot magnets are manufactured from standard parts according to DIN EN ISO 4017-8.8. Dimensions and tolerances depend on the current status of the standard. Hexagon screws are suitable for being tightened with an open-end spanner. This is a special advantage in comparison to our round flat pot magnets, which only can be screwed on by hand. The hexagon screws are available with different lengths corresponding to fixed standards. By this simplified production method they are quite economical resp. there is a cost benefit compared with the turned special parts.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned flat pot magnets are manufactured from standard parts according to DIN EN ISO 4026-45H. Dimensions and tolerances depend on the current status of the standard. The threaded pins with hexagon socket have a universal thread and are available with different lengths corresponding to fixed standards. By this simplified production method they are quite economical resp. there is a cost benefit compared with the turned special parts. Moreover, through the universal thread, they benefit from a continuously adjustable magnetic attachment point.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

We also manufacture permanent magnet lifting trusses according to your individual requirements. As a load-bearing load beam or light spreading beam with two or more magnets, the possibilities are manifold. FXE-T truss solutions with onBoard control technology are operated directly on mains voltage and can therefore be used very quickly on different cranes without individual control installation. Flaig Magnetsysteme offers trusses for all sheet metal formats, beams and profiles and also for clearing cutting tables in just one stroke.

Request for a quote

STRONG MAGNETS GMBH

Germany

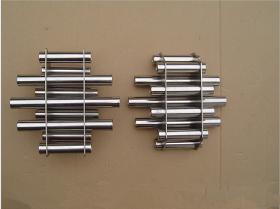

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

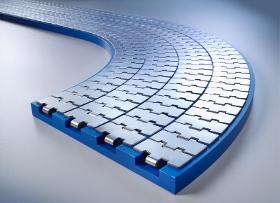

iwis Magnetic radial corner bends Having optimized magnet fluxes around the curve layout, the new generation of FLEXON Maxxtop Magnetic corner tracks from iwis virtually eliminates pulsation and can help reduce tensile forces in our curves by up to 60 %. FLEXON Highlights - Up to 60 % less tensile force than previous magnetic corner tracks - Reduced power consumption - Guaranteed energy saving - Possibility of longer conveyors reducing cost - Reduced chain wear - Reduced pulsation increases product stability - Quieter operation improves environmental conditions for employees - Excellent friction co-efficient properties reduces chain wear - Excellent material quality offers longer service life - FLEXON Maxxtop Magnetic corner tracks are available in all standard sizes - FLEXON Maxxtop Magnetic corner tracks can be manufactured to drawings

Request for a quoteResults for

Magnet manufacturer - Import exportNumber of results

7 ProductsCountries

Company type