- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnet manufacturer

Results for

Magnet manufacturer - Import export

STRONG MAGNETS GMBH

Germany

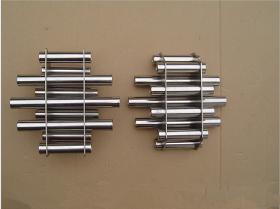

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

STRONG MAGNETS GMBH

Germany

Produced by the powder metallurgical method with chemical composition of ND2Fe14B Very brittle and hard Poorest corrosion resistance of all commercial magnetic material High resistance to magnetic demagnetization Excellent cost to performance ratio Reasonable temperature stability Not suitable for application which exposed to high temperatures Earth permanent magnet (NdFeB) has the strongest magnetism nowadays.It does not only has high remanence, high coercivity, high energy product, and highfunctional, but also it can processed into a variety of sizes easily.Now, it is widely used in avigation, spaceflight, electron, electrical sound, electrical machinery, apparatus, meters, medical technology, and especially apply to develop highperformance, small and light replacements. Our factory produce and manufacture magnets according to customer's design on shape, dimension, grades, coatings etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Magnet manufacturer - Import exportNumber of results

3 ProductsCompany type

Category