- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- log system

Results for

Log system - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Logistics software solutions to optimise your work process The software house of Lödige Industries LogIT GmbH, the software house of Lödige Industries, has 30 years of experience in data processing and host systems in the field of logistics. Based on standardized software modules, we develop solutions tailored to the specific projects of our customers. Experience, practical knowledge and competent handling are guaranteed by specialists in data and information processing. Storage management, material flow and transport technique, data base applications are implemented in state of the art logistics software. LogIT GmbH realizes and optimizes business processes within the logistic chain, from primary production to recycling. Our products include: Manual consignment solutions for distribution centers (MAN-Log) Truck dock management (TRUCK-Log) Air cargo systems (Cargo Professional)

Request for a quote

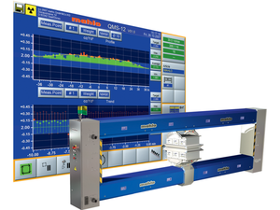

MAHLO GMBH & CO. KG

Germany

Web process control The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight, coating weight, thickness, moisture etc.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes finishing The Orthopac VMC is a modular process control system for textile refinement. It optimises drying or fixing processes as well as the processes all about the stenter. The system measures, logs and controls critical process parameters over the entire working width like temperature, dwell time, residual moisture, exhaust air moisture, thread density, basis weight and more. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met. The system can also be integrated into an Orthopac straightening system. It thereby combines the functionality of a weft straightener with that of a process control system in one compact device.

Request for a quoteMPT DOSING GMBH

Germany

WPH webReady The pH/ORP on-line process controllers are designed for industrial, commercial, and municipal water treatment applications. The output configuration allows you to program up to four outputs in a variety of control modes. Select from on/off mechanical relays or pulse proportional control for direct connection to metering pumps. The easy-to-use menu format and pre-wired, pre-mounted panel system options make set-up and installation quick and simple. Integrated data logging is available to validate system performance. With a USB memory stick data and event logs that include electrode measurements, temperature and relay status can be extracted. Then download log files from the USB stick to a PC. Product features: Range of applications Select from pH or ORP measurements and from five output options. Use In-Range to control a solenoid valve to dump a batch treatment tank when measurement value is within limits, or program for Out-of-Range Alarm in waste treatment applica

Request for a quote

MPT DOSING GMBH

Germany

Controller for electroless nickel baths / Controller for electroless copper baths Controller for electroless nickel baths Nickel controller with flow-through sensor Walchem's WNI Nickel Controllers are optoelectronic on-line analyzers that measure the actual concentration of nickel in solution. The WNI410 is available as nickel-only, or with a pH control option which may be added in the field. Two separate pump outputs for nickel and reducer and another for pH are used, each of which is capable of totalizing either pump on-time, volume pumped, or metal turnovers. Integrated data logging is available to validate system performance. With a USB memory stick data and event logs that include nickel measurements, and relay status can be extracted. Download logs from the USB stick to a PC. Product features: Concentration Read in Units Selectable between grams per liter (g/L) or ounces per gallon (oz/gal). Backlit digital display also acts as a bar graph for a continuous "visual summar

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OSMO MEMBRANE SYSTEMS GMBH

Germany

Construction of customized pilot plants Osmo Membrane Systems GmbH is very experienced in layout, manufacturing and start-up of pilot plants. From a container-installed plant which can be designed frost-proof, up to commercial Pilot plants with remote control and online integration, our product range covers a multitude of applications. Depending on the task, we rent an existing pilot plants or we design a new one. Our product range covers laboratory plants like our plant “MemCell” up to large scale plants. The plants can be delivered with an individual visualization. So, this includes data logging and remote control. By request, the plants may be delivered with a customized visualisation system. You are able with the process control system (PCS) to control the plant and a measurement data logging / interpretation system is implemented too. On customers request a secured remote maintenance and remote control will be also installed.

Request for a quote

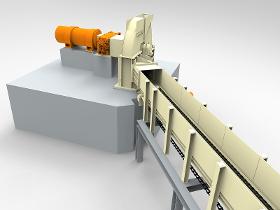

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of berboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Key features Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Options Horizontal convey for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The line for tree-length logs is designed for the processing of whole logs with lengths of up to 20 meters: With the log feed, debarker, washing system, dosing system all the way to the highly-efficient disc chippers, the production of high-quality chips is guaranteed. Features, Function Feeding of the wood from the truck or storage area Large gantry or rotating cranes for loads of up to 30 metric tons of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The OSB line is designed for processing logs with lengths between 3 and 4 meters and diameters between 50 and 850 mm. With the log feeder, debarker, dosing system, bundle maker all the way to the world‘s largest knife-ring flaker, the production of high-quality strands is guaranteed. Features, Function Feeding wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The line for tree-length logs is designed for the processing of whole logs with lengths of up to 20 meters: With the log feed, debarker, washing system, dosing system all the way to the highly-efficient disc chippers, the production of high-quality chips is guaranteed. Features, Function Feeding of the wood from the truck or storage area Large gantry or rotating cranes for loads of up to 30 metric tons of...

Request for a quoteResults for

Log system - Import exportNumber of results

14 ProductsCountries

Company type