- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- systeme

Results for

Systeme - Import export

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

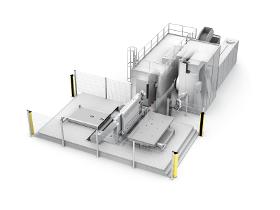

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for highspeed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5axis simultaneous machining process. At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life

Request for a quote

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life.

Request for a quote

3D-MICROMAC AG

Germany

The microDICE™ laser micromachining system leverages TLSDicing™ (thermal laser separation) – a unique technology that uses thermally induced mechanical forces to separate brittle semiconductor materials, such as silicon (Si), silicon carbide (SiC), germanium (Ge) and gallium arsenide (GaAs), into dies with outstanding edge quality while increasing manufacturing yield and throughput. Compared to traditional separation technologies, such as saw dicing and laser ablation, TLS Dicing™ enables a clean process, microcrack free edges, and higher resulting bending strength. Capable of dicing speeds up to 300mm per second, the microDICE™ system provides up to a 10X increase in process throughput compared to traditional dicing systems. Its high throughput, outstanding edge quality and 300mm wafer capable platform enables a true high volume production process, especially for SiC based devices.

Request for a quote

3D-MICROMAC AG

Germany

The microMARK™ MCF is a premium engraving system. Using an UV excimer laser results in a superior engraving quality considering all cosmetic aspects – without any heat affection and micro cracks. The system is suitable for marking of all kinds of materials and coatings including highindex, tinted, and coated lenses. The microMARK™ MCF is the right choice for concave or convex as well as for blocked and unblocked lenses. The industryapproved system guarantees maximum throughput and availability. Premiumquality excimer laser marking Technical engraving and branding on all kinds of lenses and coatings UDI marking of hard and soft contact lenses Maximum throughput by automatic handling Superior availability by second laser source

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s laser system microMARK™ RXe has revolutionized the efficiency of blocked lens engraving by using excimer lasers. Equipped with an optimized optical components setup and a large sized magnification ratio, this new generation of RX marking devices offers an increased depth of focus at lowest laser power operation on all materials. Customers benefit from low investment and small operating costs. High quality engraving Accurate contrast adjustment Low investment and operating costs Reliable process stability Smallest excimer system footprint available on the market High quality engraving with accurate contrast adjustment on a variety of spectacle lenses and coatings Smallest required space on the market Low investment and operating costs Easy retrofit of automated handling system at customer’s site on request

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microSTRUCT™ C is a highly flexible laser micromachining system predominantly used in product development and applied research. Superior flexibility makes the system ideally suited for laser structuring, cutting, drilling and welding applications on a variety of substrates, e.g. metals, alloys, transparent and biological material, ceramics and thin film compound systems. The microSTRUCT™ C offers a maximal degree of freedom regarding the positioning of the substrates. Flexible, stable and repeatable machining results Two independent and free configurable working areas with various optical setups Open system concept for the integration of different laser sources High range of software functions (Masterscript) User friendly, flexible, upgradeable system

Request for a quote

SUVIS GMBH

Germany

Another working area of the Suvis GmbH is the field of innovative sensor systems applied to particle and flow measurements taking into account microsystems. We develop novel flow and particle sensor systems for the application in environmental technology, process and mechanical engineering, and automotive technology. Important aspects are robustness and economicalness of the complete sensor system in order to create for the above mentioned application fields practical and affordable solutions. The respective sensor system will be developed as a whole solution. This means besides the hardware set up that we also take care of the evaluation of the sensor signals with our own solutions. We develop from scratch up to prototype level including periphery technology development. Please contact us for a not binding offer. We would like to know more about your challenge!

Request for a quoteResults for

Systeme - Import exportNumber of results

16 ProductsCountries

Company type