- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- joints

Results for

Joints - Import export

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie DP 2,75 bar DT 250° C ax. mov. -20 mm lat. mov. +/-8 mm

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie outside material: 2.4610 inside material: PTFE (s=5mm) DP 10 bar DT 230° C ax. mov. +/-30 mm

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie exhaust expansion joint DN500 with a bend segment DP 0,5 bar DT 550° C ax. mov. +/-20 mm lat. mov. +/-20 mm

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie chamber expansion joints DN50 / DN150 / DN200 DP inside 6 bar DP outside 4,5 bar DT 155° C ax. mov. +/-15 mm lat. mov. +/-10 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLEXOMAT GMBH

Germany

Lateral expansion joints absorb movements vertical to the bracing plane. The reaction forces caused by the internal pressure are absorbed by the joint mounting. Under internal pressure expansion joints generated pressure reaction forces. For a better understanding, the following considerations with different diamaters, pressures and resulting from it the forces: DN 150 -> 25 bar ~ 80 kN = 8 t DN 300 -> 10 bar ~ 100 kN = 10 t DN 1000 -> 1.5 bar ~ 130 kN = 13 t Due to high forces, movements in pipelines of higher nominal size and higher pressure can only be absorbed with braced expansion joints. Applying braced expansion joints pressure stress can be absorbed, while fixed bearings can be dimensioned smaller. In case a 3-hinge-system cannot be applied due to missing space, special-purpose solutions like pressure-balanced expansion joints can be installed. Types of design for lateral expansion joints: ball bearing types with tie rods for all-side movements cross hinged types for...

Request for a quote

FLEXOMAT GMBH

Germany

Universal expansion joints absorb axial, lateral and angular movement simultaneously. Installation is primarily in the low pressure area. Using a guide tube protects the metal bellows from abrasive media or flow-induced oscillations. The reaction forces caused by the internal pressure must be absorbed by sufficiently dimensioned anchor points.

Request for a quote

FLEXOMAT GMBH

Germany

Axial expansion joints compensate assembly tolerances and thermal longitudinal expansion in the direction of the tube axis. Depending on the design, they can be impinged with pressure internally and externally. Using a guide sleeve protects the metal bellows from abrasive media or flow-induced oscillations. The reaction forces caused by the internal pressure must be absorbed by sufficiently dimensioned anchor points.

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie DP 1,2 bar DT 143° C ax. mov. +/-18 mm lat. mov. +/-23 mm

Request for a quote

PANEL SELL GMBH

Germany

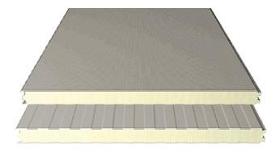

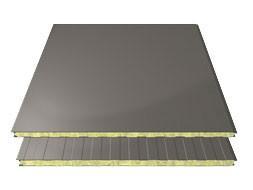

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

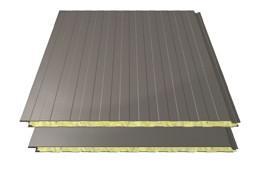

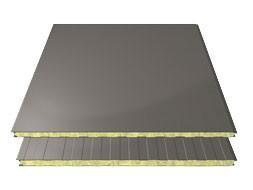

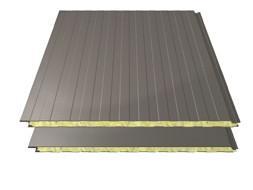

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteResults for

Joints - Import exportNumber of results

16 ProductsCountries

Company type

Category