- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- leak test benches

Results for

Leak test benches - Import export

MERECS ENGINEERING GMBH

Germany

We develop and build test stands for pumps and can refer to several references in this field. In addition, we build press-off facilities and design them individually, including suitable risk assessment. Our process visualisation is suitable for customer presentations of the running pumps directly at the pump test stand. In addition, Merecs Engineering provides the connection to the IT infrastructure of our customers (ERP systems or databases). - Planning, calculations and construction - Coordination of suppliers - LabVIEW software development - NI-Real-Time & FPGA for high-speed evaluation of speed and acceleration measurement values - Vibration analysis via FFT (updated live) - LabVIEW, NI-cRIO and Siemens S7-1500 PLC in combination possible - Database connection - On-site assembly and IB

Request for a quote

MERECS ENGINEERING GMBH

Germany

We are experienced in test system development for leakage testing, life time testing and end-of-line test stands in the field of gas & hydrogen technology. We also have a network of suppliers and partners who provide key components for leakage measurement, piping, sealing and instrumentation. As a general contractor and integrator, Merecs Engineering can individually design, assemble and commission the test system at our customers' sites.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to ensure that castings, valves, pumps, hoses and other components or groups have been manufactured free of leakage, they are tested in non-destructive leakage tests. Oxygen, air, nitrogen or sulfur hexafluoride (SF6) can be used as the test medium.

Request for a quote

MERECS ENGINEERING GMBH

Germany

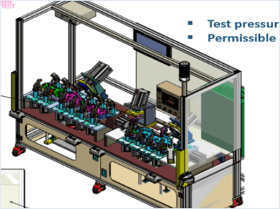

We design and manufacture individual test systems for the pressure testing of valves and pumps. Merecs Engineering has a competent network of partners for this purpose. Within this framework, we carry out the risk assessment, design, manufacturing, installation and commissioning. In addition, we connect the systems to the individual IT infrastructures (databases, ERP systems, MS PowerBI) of our customers.

Request for a quote

MERECS ENGINEERING GMBH

Germany

EOL test stand for e-charging columns and their power electronics for the simulation of different electrical loads and mains fluctuations. The test stand has automatic contacting and achieves high test throughputs in end-of-line operation. Different variants of the power electronics of electric charging columns can be tested. On the software side, Merecs Engineering relies on NI-LabVIEW and NI-TestStand.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CETA TESTSYSTEME GMBH

Germany

The CETATEST 715 series includes fully automatic working leak tester for the detection of untight parts within the cycle time of the production process. The leak tester uses a gauge pressure sensor and has a large measurement range. Therefore the CETATEST 715 is especially qualified for the simple testing of parts with large leakages, as they occur in the testing of valves. The test types "sealed component" and "dynamic pressure" can also be integrated. Typical applications: Testing of sanitary fittings, plastic welds, check valves Operating methods: Single-channel operation, two-channel operation The measurements in two-channel operation are synchronous. Measurement ranges: Max. +/-10,000 Pa Result units: Pa, hPa, PSI, Pa/s, hPa/s, mbar*l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr Pressure ranges: -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar, 16 bar, 20 bar, negative gauge pressure and positive gauge pressure ranges can be combined.

Request for a quote

CETA TESTSYSTEME GMBH

Germany

Pressure ranges: -1 bar, +/- 5 mbar, +/- 50 mbar, 200 mbar, 1 bar, 6 bar, 10 bar, 20 bar, 30 bar, 400 bar (high pressure version), negative and positive gauge pressure ranges can be combined. Measuring ranges: ± 500 Pa / ± 5,000 Pa (display resolution: 1 Pa, internal resolution: effectively 0.01 Pa) Result units: Pa, hPa, PSI, Pa/s, hPa/s, mbar • l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr Types of test: Standard: Pressure decay Optional: sealed component, dynamic pressure measurement, pressure steps, pressure rise (with double leak connector) Parameters can be exported to a USB stick or imported again. The storage of measurement series and waveforms is possible. Interfaces: Standard: Digital I / O, RS-232 Optional: Profibus DP, Profinet, Ethernet, EtherCAT, Bluetooth, USB Dimensions: 345 mm x 145 mm x 435 mm (W x H x D) In the high-pressure version, leak tests up to a test pressure of 400 bar can be carried out according to the pressure rise method.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Package Leak Detection system using a water-based bubble test. LEAK-MASTER® EASY allows the detection even of the smallest of leaks. After the package is placed into the chamber filled with water, the head space above the water level is evacuated using a venturi vacuum (compressed-air) system. This causes the package immersed in the water to inflate, allowing any leaks and their location to be identified by a stream of bubbles. Benefits: economical and uncomplicated visual inspection allows localisation of the leak for all flexible and rigid kinds of packaging (food-, pharmaceutical-, industrial- and other packaging) short testing period (< 30 sec.) easy-to-use intuitive operation – no special skills required easy installation and start-up no trace gas required in package can also be used for altitude simulation optionally also for vacuum packaging, set order-No. 956992700 no calibration required various chamber sizes avail

Request for a quoteResults for

Leak test benches - Import exportNumber of results

10 ProductsCountries

Company type